Specific welding processes use various types of equipment. And although tack welding might seem like a separate process, it is a particular application of any welding process. It amounts to applying tiny beads of weld throughout the joint’s length to hold metal pieces in position so they can be welded. The joint’s length, metal type, thickness, and geometry determine the number of tack welds.

Every welder must know tack welding as a fundamental skill since many welding jobs require tack welds, especially those with complex joints. This article will explain how tack welding works, the different types of tack welding, when you would use it, and its pros and cons.

How does tack welding work?

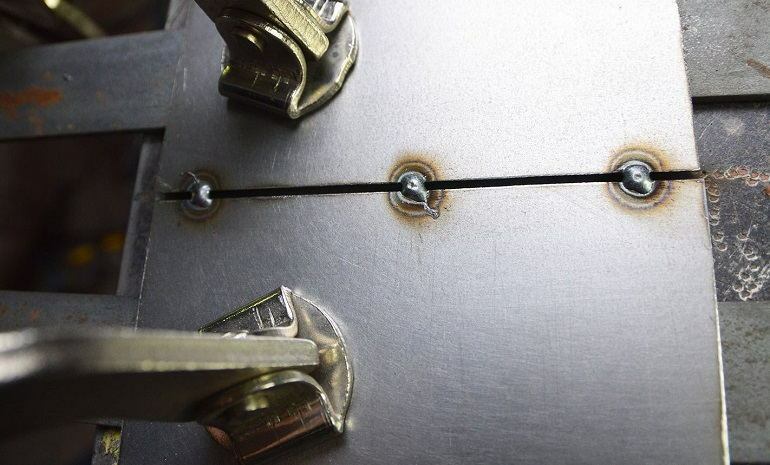

You tack weld using the same method as you’ll use for the final bead. However, instead of welding several inches, you would add a few small 1/4 to 1/2-inch long tacks along the workpiece to stabilize it. Tacking, as it’s often called, keeps the parts of a weldment in correct alignment while the welding occurs. Its significance is obvious; mess up the tack welding, and you’ll ruin your work.

Although welders sometimes hold a joint in place with clamps or magnets before tack welding, these fixtures might not hold the joint geometry when it’s under internal or external welding stresses. Since tack welds can endure these forces better until the weld seam is finished, it is a preferred method for getting quality welds.

What are the different types of tack welding?

Welders can choose from three types of tack weld: standard, bridge, and hot tack weld. Here is how they differ:

1. Standard tack welds are meant to be consumed during the final weld

The primary purpose of standard tack welding is to hold two pieces of metal in the correct position and should not be visible after the final welding. Tack welds are placed within the weld joint; if sized correctly, they will disappear into the final weld.

Tack welding is all about striking the right balance. They must be large enough to handle the material’s weight and heat during the welding process yet small enough to ensure they do not show after the permanent welding and assembly is completed.

2. Bridge tack welds are used across gaps

If a fit-up leaves a gap to be filled with weld, the bridge tack is used across the gap. These gaps may occur when the material is cut too short in the shop or arrives from the supplier with distortion.

One way to bridge the gap is to apply a weld in a sweeping motion. You must be careful not to use too much weld at once so it doesn’t get too hot and fall through the gap. Taking breaks between quick passes will keep the temperature down.

Another method is to apply small tacks to each side, alternating to allow the other side to cool. Eventually, you will reach the middle of the gap and join both joint sides. This method is more time-consuming and works best with MIG or flux-cored welding. Remember, bridge tacks do not penetrate the joint’s root, and you grind them off after the first root pass.

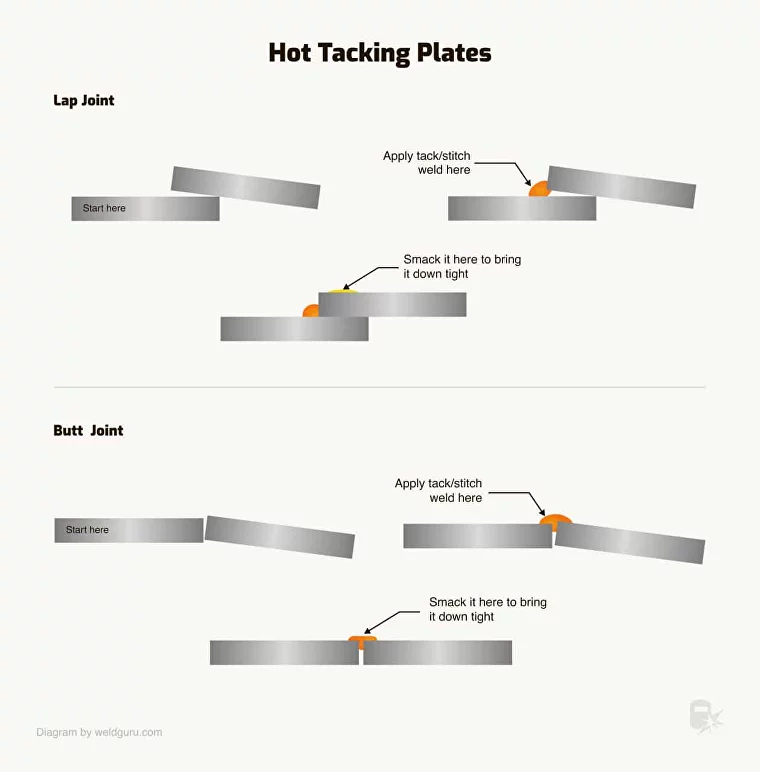

3. Hot tacking can also close a gap

If weld quality is not high on your list of concerns, you can bridge a significant gap using excessive heat and filler and hammering it in place. The extra heat can cause a powerful contraction, and as the metal cools, you can beat the gap closed. Keep in mind that this is not an ideal method of tack welding, and many welding codes do not allow it.

Where is tack welding used?

Tack welding can happen wherever you perform any welding, but you’ll see specific types used more in particular industries. For example, you’ll find large bridge and hot tacks more frequently when working with structural steel, as in fabrication shops and building construction.

You’re unlikely to see much hot tacking in TIG welding because the lighter gauge material involved would not tolerate a good beating. However, since thinner stainless is susceptible to heat distortion, smaller tacks are used to help stay within the tight tolerances on blueprint dimensions.

Although all types of welding employ tack welding, sometimes it’s not practical. Tacking typically eliminates the need for fixtures, but some industries find it more efficient to use them. For instance, companies fabricating dozens of one type of weldment each day will choose machined fixtures over tack welding to hold tighter tolerances and be more productive.

Also, want to read about Gas Welding Types?

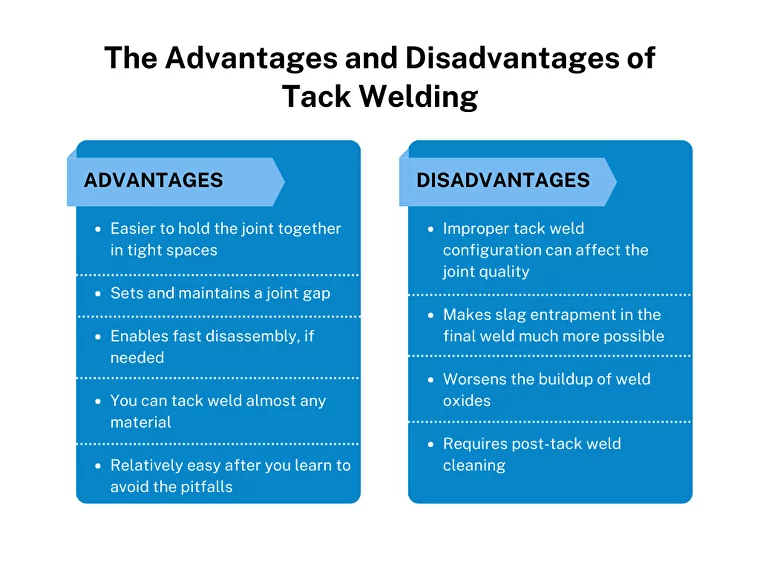

The advantages of tack welding

Tack welding allows welders to hold metal parts in place better than clamps or by hand. It saves the time and expense of building a fixture each time you assemble a weldment, and it prevents distortion during welding better than clamps. Here are a few other benefits:

· It’s easier to hold the joint together in tight spaces

· Sets and maintains a joint gap

· Enables fast disassembly, if needed

· You can tack weld almost any material

· It’s relatively easy after you learn to avoid the pitfalls

Book a 60-minute demo to see

how eziil mrp solution works for you

Some disadvantages of tack welding

One of the few downsides to tack welds is they initiate quick, localized heating and cooling, and some materials don’t handle that well. Also, some hard and brittle steels require a specific tack welding procedure since it could cause hard and crack-sensitive spots, meaning only the most qualified welders should work on these steels. A few other difficulties include:

· Improper tack weld configuration can affect the joint quality

· Tack welding makes slag entrapment in the final weld much more possible

· Worsens the buildup of weld oxides

· Requires post-tack weld cleaning

In conclusion

After you learn the correct techniques, tack welding gets easy. Welders often go wrong in placing the tacks, so ensure the tacks and heat input are evenly spaced and spread out, and you’ll prevent many tack welding issues.

Also, learn to find the right balance between the number of tack welds and their size. Practice tack welding on a piece of scrap metal, and you’ll soon know the best tack weld configuration every time.