If you run a metal fabrication shop with anywhere from 10 to 200 employees, you probably know how demanding it can be. You’re facing a new set of challenges every day: special customer requests, design tweaks, and juggling multiple jobs at once. And if you don’t keep tight control over your schedule, materials, and costs, things can escalate fast. And that’s exactly where a Manufacturing Execution System (MES) comes in handy.

A manufacturing execution system may sound like something only large corporations need, but in reality, smaller metal fabrication shops can reap huge rewards and increase their profits by putting an MES in place—especially those that do project-based or highly customized work.

In this article, we’ll walk through what an MES is, why it’s so helpful for small-to-midsize fab shops, and how a solution like EZIIL Starter can bridge the gap between “organized chaos” and streamlined efficiency.

What is Manufacturing Execution System, exactly?

A Manufacturing Execution System (MES) is a software that coordinates, monitors, and records every step of your production process—from the moment you approve a job all the way to finishing and shipping the product.

You can think of it as:

- Your production control tower: It tells you what’s happening on the shop floor in real time.

- A central data repository: It keeps all the important records—like which materials you used, the steps you followed, who performed the work and how long it took them.

- A tool for scheduling and tracking: It updates everyone on changes, ensures quality checks happen, and captures any deviations from the plan.

In a nutshell, MES is a good place for small metal manufacturers to start from to ease into digital project management — it will have a significant immediate impact on production speed and efficiency. However, if you already have an ERP system (Enterprise Resource Planning) in place to help you handle financials and purchasing, MES will complement it by focusing on day-to-day, minute-by-minute shop-floor operations.

Key functions of a Manufacturing execution system

- Production scheduling and resource allocation: Dynamically plan which machine or workstation does what, at what time.

- Shop floor visibility: See which jobs are in progress, which ones need immediate attention, and how close you are to completion.

- Quality and traceability: Track weld parameters, materials used, and inspection results in one place.

- Inventory and materials management: Know if you have the right plates, tubes, or bar stock for tomorrow’s job.

- Data analytics: Spot trends in rework rates, cycle times, or potential bottlenecks.

MES vs ERP vs other systems

It’s easy to confuse an MES with other manufacturing software acronyms.

Here’s a quick comparison to help you grasp the concept:

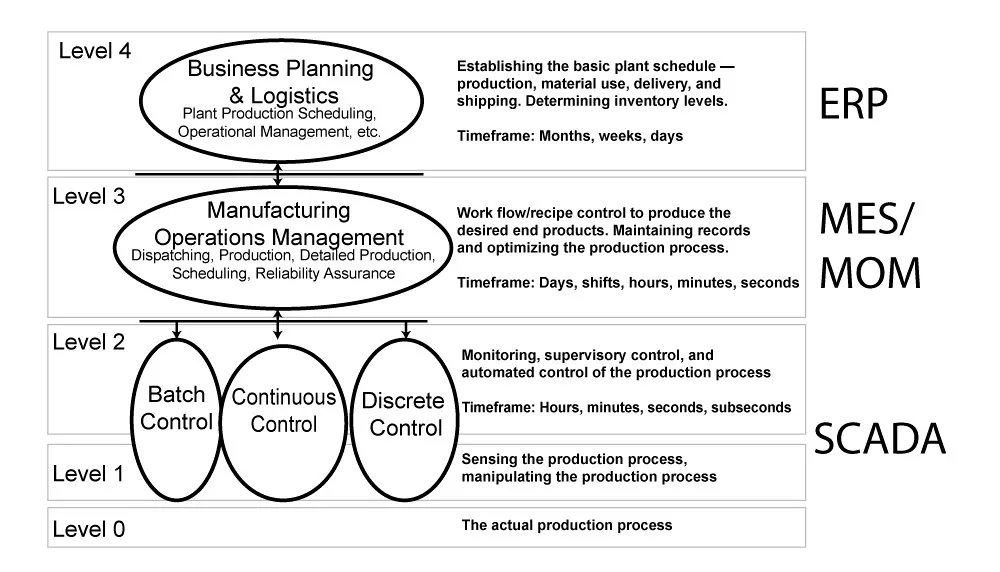

- ERP (Enterprise Resource Planning): Focuses on business-level functions—like quoting, financial accounting, purchase orders, and high-level scheduling.

- PLM (Product Lifecycle Management): Handles product development stages, revisions, and engineering data.

- SCADA or PLC systems: Equipment-level control, sensors, and automation on the factory floor.

MES sits in between ERP and the machine control systems when it comes to bigger productions. It translates the “what” and “when” from the ERP into the “how” on the shop floor. If the ERP is the brain, you can think of the MES as the eyes, ears, and hands that coordinate and track the actual work as it happens.

However, very often in smaller fab shops, where there’s no need for a full-blown ERP system yet, MES is a standalone solution to help coordinate and optimize project workflow.

Why is this important for small/medium metal fab shops?

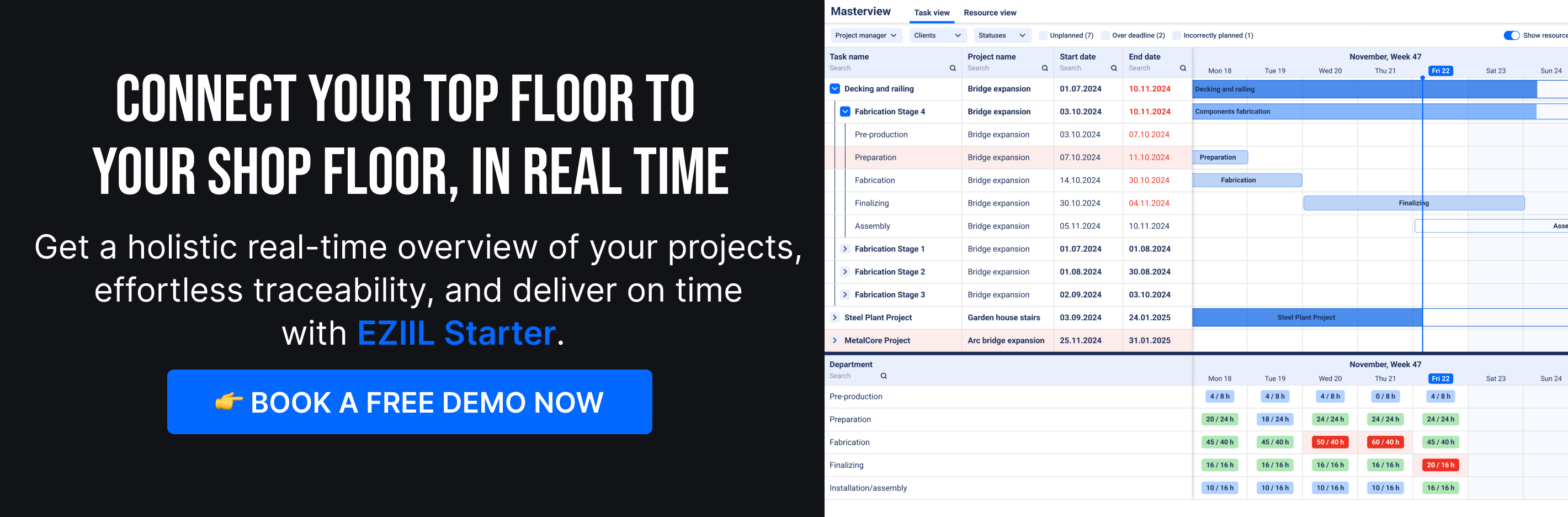

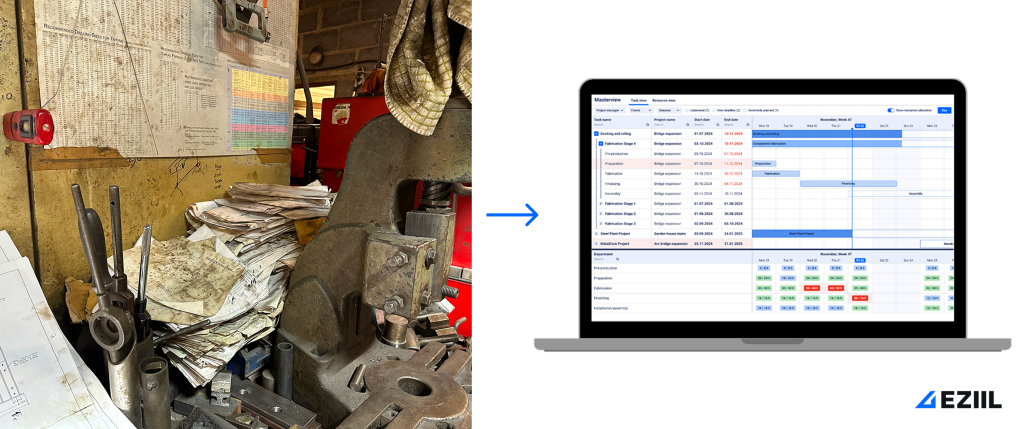

You might not have super sophisticated automation with SCADA/PLC systems, and your ERP might be doing only basic resource planning. Or you might even still be using pen and paper or disconnected tools like Excel and Google Drive to plan and track your projects and run your business. An MES like EZIIL Starter bridges the gap by organizing daily tasks, digitizing your production steps, and feeding back real-time insights to management.

Why metal fabricators need a Manufacturing Execution System in the first place

Your first question might be: “Aren’t MES tools for giant factories?” Sure, many large global manufacturers rely on sophisticated MES platforms. But in today’s fast-changing world, even a job shop with 50 employees will immensely benefit from the real-time visibility and digital record-keeping that an MES provides.

Common pain points for project-based metal fabricators

Real-time (or lack thereof) visibility

An MES connects the “top floor” to the “shop floor” in real time—so instead of waiting for end-of-day (or end-of-week) updates, you know exactly what’s happening as it happens*.* For example, if a project is running behind, you’ll get an alert and can decide whether to add more manpower or prioritize certain tasks. That means fewer surprises, quicker decision-making, and more efficient use of your resources. For metal fabricators who often juggle multiple custom jobs at once, real-time visibility is critical to staying profitable and delivering on time with confidence.

Estimation vs reality

Project-based shops often quote based on experience (or best guesses). But once the job’s underway, it’s all too easy to underestimate labor hours or forget about extra rework. An MES keeps tabs on who’s doing what and how long it takes, so you’ll see accurate costing data for future quotes.

Traceability: material certifications and compliance

If you’re working on structural steel components, or jobs requiring certain weld qualifications, you need to maintain a paper trail of material certs and welding logs. Even if you’re not in a heavily regulated sector, you may still need to produce verifiable QA records—often at short notice. An MES can store these documents digitally and link them to the specific job. That way, if your customer or an auditor ever asks, you can retrieve them in seconds rather than sifting through filing cabinets.

Custom, project-based orders

Every job is different, from big welding assemblies to small bracket orders. Tracking specs, drawings, tasks and project progress across multiple spreadsheets can get messy fast. MES keeps all your project data, from drawings and specs to tasks and scheduling in one place, eliminating the risk of miscommunication and making sure your team is aligned at all times. Additionally, setting up and preparing new projects without an MES might take you weeks, whereas an MES will let you set up a new project, plan and sequence the tasks in minutes.

Handling frequent design updates

Metal fabrication is rarely straightforward. Clients make changes, or your own design team sees a need to tweak the design to reduce costs. An MES helps ensure everyone on the shop floor sees the latest, correct prints and work instructions—no more outdated drawings taped to someone’s station.

Limited manpower

Unlike huge factories, smaller fab shops don’t have a full department of process engineers or data analysts. It’s usually the opposite: many smaller shops rely heavily on a handful of experienced people who hold critical knowledge in their heads. When they’re out of office or overloaded, the entire operation is at risk. So capturing real-time data in a user-friendly system matters a lot. This is where an intuitive and easy-to-adopt platform like EZIIL Starter can save you from “tech overwhelm.”

Last-minute schedule shifts

Supplier delays, last-minute “urgent” jobs, or a higher priority from a VIP customer can throw off your well-intentioned Gantt charts or whiteboard schedules. If you’re asked to stop Job A midstream to tackle a more urgent Job B, a manufacturing execution system software quickly updates the schedule and notifies relevant operators. No more yelling across the shop or forgetting to tell the night shift about the new priorities.

How can tools like EZIIL Starter help?

EZIIL Starter was built from the ground up with smaller, project-based metal fabrication shops in mind. Instead of forcing you to adopt a rigid, enterprise-level process, it offers a user-friendly experience that’s easy to set up and maintain on a lean budget—meaning you won’t need extensive IT resources or a background in advanced manufacturing software.

It’s a flexible solution especially in environments where frequent design changes and high-mix, custom jobs are the norm. Whether you’re revising an existing part mid-production or juggling multiple smaller runs, EZIIL Starter keeps all your project data, tasks, and schedules in sync so your entire team—machine operators, welders, office staff—stays on the same page. By removing guesswork and manual spreadsheets, it helps you achieve real-time visibility, fewer errors, and quicker job turnarounds without drowning in complexity.

How to implement a Manufacturing execution system in a small-to-midsize metal fab shop

So, how do you go from spreadsheets and guesswork to a fully functioning MES? Let’s take a look at some of the best practices to keep in mind:

- Define clear goals and KPIs. Decide what success looks like. Maybe you want to cut rework by 20%, reduce lead times for custom orders, or improve your on-time delivery rate. Document these goals to measure progress once your MES is up and running.

- Select the right platform. For smaller shops, find an MES that’s affordable, easy to install and doesn’t require an entire IT department to maintain. Cloud-based options like EZIIL Starter are popular because they don’t involve a steep learning curve, are budget-friendly and let you enrol the system out gradually, at your own pace, keeping each department involved in each stage.

- Clean up your existing data. Make sure your part numbers, customer info, and job templates are up to date. A new system can’t fix old, inaccurate data. If you have hundreds of part codes, maybe start with your top 20 or 30 to keep the transition manageable.

- Train your team. Emphasize the “why”: Show your operators and supervisors how the MES will make their jobs easier, not harder. Short, hands-on sessions tend to work better than long, theoretical lectures.

- Incremental rollout. As you refine the system in your pilot area, gradually expand to more processes or product lines. With EZIIL, you can layer on modules, without having to pay for a full-blown set of features that you won’t even use initially, whenever you’re ready.

Real-world examples

How a 50-Person custom weld fab shop supercharged their production in six months

Challenge: For decades, the weld fab shop used email threads and a giant whiteboard for scheduling. When urgent orders came in, it caused chaos because nobody knew which jobs to bump or who to notify.

Solution: Implementing a lightweight MES (EZIIL Starter) let them rearrange schedules digitally, send notifications to each operator’s station, and keep a record of changes.

Result: They reduced back-and-forth communications by 70% and improved on-time delivery from 65% to 85% within six months.

A steel frames manufacturer significantly reduced reworks with EZIIL

Challenge: Frequent rework due to outdated specs on the floor. Operators were using last week’s blueprint, leading to scrap and lost hours.

Solution: With the EZIIL in place, any design changes automatically updated the digital job card.

Result: The steel frames manufacturer cut rework in half and saved thousands of dollars in material costs each quarter.

These aren’t isolated success stories. Across the industry, shops that adopt an MES typically see improvements in efficiency, quality, and the ability to handle more projects without adding overhead.

Explore EZIIL customer stories here.

Future trends in MES for metal fabrication

Even for smaller shops, technology is advancing at a remarkable pace. Here are a few things on the horizon:

Cloud-based systems

Cloud-based MES solutions are becoming the norm, especially for SMEs that can’t afford complex IT. This means remote access—check job status from your smartphone if you need to.

AI auto-scheduling

Some advanced systems are experimenting with AI to automatically shuffle jobs based on priority, machine availability, and operator skillsets. This next level of optimization is still evolving, but it’s coming.

Deeper CAD/CAM integration

Imagine changes to a CAD design automatically updating every station’s instructions in real time. That’s the goal. MES solutions will increasingly integrate with the design side of the business for seamless, end-to-end workflows.

Predictive analytics and maintenance

By collecting data on how each job runs, how your machines perform, and when breakdowns typically occur, MES systems can help plan maintenance before big issues arise. Fewer nasty surprises, more controlled downtime.

EZIIL continues to evolve with these trends in mind, focusing on ease of use and cost-effective expansion of capabilities—so small or mid-sized fab shops can stay competitive without overextending resources.

Final words

Metal fabrication shops of all sizes face many of the same fundamental challenges: unpredictable schedules, complex orders, tight profit margins, and the need for accurate tracking. A Manufacturing Execution System helps tame these complexities by giving you real-time visibility, streamlined communication, and data-driven insights.

If you’ve been putting off looking into an MES because you assumed it was “only for the big guys,” now is the perfect time to explore a solution designed for small-to-medium metal fabricators—especially those doing project-based work. Solutions like EZIIL Starter can be implemented quickly, offer robust functionality without breaking your budget, and scale as your business grows. Once you’ve experienced the agility, traceability, and clarity an MES can bring, you’ll wonder how you ever managed without it.

In the end, an MES won’t just help you manage day-to-day operations—it will free up your best people to do what they do best: fabricate quality products, grow the business, and keep customers happy.