Make to order shops (MTO)

What is make to order (MTO) in steel fabrication?

Make to order (MTO) is a production approach where work starts after a customer order is confirmed. You’re not building to forecast, you’re building to a real spec and ship date.

MTO is great for customization, but it puts pressure on:

Quoting accuracy (because every job is a mini-project)

Material readiness (late purchasing becomes late production)

Capacity planning (too many promised ship dates, not enough welding hours)

Visibility (you can’t hide behind inventory)

Best practices for make to order job shops

Quote with capacity in mind: your backlog is a promise, not a wish

Gate the release: don’t release to the floor until drawings, materials, and approvals are ready

Use realistic internal milestones (fab complete, coating complete, packing complete)

Keep WIP controlled: MTO shops drown when everything is “in progress”

Do quick post-job reviews: what was planned, what happened, what changes for next quote

How EZIIL helps Make to order steel shops

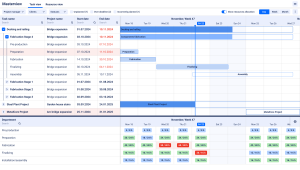

EZIIL was specifically built for Make to Order steel shops and fits the workflow because it treats each order like a managed project:

One place to track project scope, deadlines, and ownership across departments

Live progress updates so you can spot risk early and act while there’s still time

Plan vs actual insights that improve quoting and job selection over time

Clear alignment between engineering, production, and delivery dates