Cross training the crew in custom steel fabrication is one of the most practical ways a small shop can protect on-time delivery and reduce day-to-day chaos.

In most custom metal fabrication shops, the “system” behind production, is a handful of dependable people, tribal knowledge, and whatever planning tool has grown over time (often a mix of whiteboards, spreadsheets, and pen/paper). It works, until it doesn’t. One key welder is out, the only person who can program the plasma is tied up, or your planner gets pulled into a customer fire drill, and suddenly the whole week starts slipping.

That’s the hidden risk of small-team specialization. When critical skills live in one person’s head, you end up with single points of failure that create bottlenecks, overtime, rushed handoffs, quality misses, and stressful “hero mode” saves. The shop might still ship, but it costs margin, energy, and trust with customers.

The good news is you don’t need to double headcount to get more reliable output. With a focused approach to cross training (not “train everyone on everything,” but building backup coverage for the steps that control flow), you can make your schedule more resilient, spread the load more fairly, and improve performance without burning out your best people. This article breaks down why cross training matters in custom steel fabrication, where it pays off fastest, and a simple way to start that fits into real production weeks.

What cross training actually means in a steel fab shop

Cross training in a steel or metal fabrication shop is not about “everyone learns everything.” In practice, it’s a targeted coverage plan for the handful of steps that keep jobs moving when things get messy.

Actually, most shops already accidentally cross-train. The classic “fab guy” ends up fitting, welding, grabbing material, running the crane, maybe even jumping on the plasma table when it’s on fire. Or as one shop manager summed it up bluntly: the most valuable people are the ones who can fit, weld, run the plasma table, operate the cranes and forklifts, because they’re the ones who keep work flowing when the plan breaks.

The difference between accidental cross training and targeted cross training is this: you decide which skills need backup, who gets trained, and what “good enough” looks like.

If you want a simple rule to guide your cross training decision, try this:

For every “keep-WIP-moving” step, have at least two people who can do standard work without supervision.

Not two people who can do it perfectly. Two people who can do the normal 80% safely and to spec. That’s it.

This matches what broader manufacturing research shows too: cross-functional training is widely used because it improves day-to-day performance, not because it’s a nice HR initiative. In the 2020 Manufacturing Institute training survey, 82.3% of manufacturers reported using cross-functional training.

It is also office-to-floor coverage. In custom fab, planning and quoting mistakes can create just as much chaos as a bad weld. So cross training matters in engineering, detailing, purchasing, and scheduling too.

The 4 types of cross training that matter most in small fab shops

1) Neighboring-process coverage (cut → kit → fit → weld → finish)

This is the most common, most realistic form of cross training, because it’s adjacent work.

For example:

- A fitter who can run the saw for standard cuts and prep kits when cutting backs up.

- A welder who can do basic fit-up and tack so welding isn’t waiting on parts.

- Someone in assembly who can jump into deburr, hardware install, labeling, packing to keep shipping from stalling.

This is exactly the kind of flexibility people describe when talking about surviving uneven demand and staffing variability. Businesses don’t run steady-state, so cross training is one of the cleanest ways to absorb the up-and-down without constant chaos.

2) “Only-one-person-knows-how” coverage (programming, setup, tribal knowledge)

In most small steel fabrication shops, the real risk is rarely the basic task. It’s the setup knowledge living in one person’s head.

Common single-point failures include:

- Plasma/laser programming and nesting

- Machine setup quirks (feeds/speeds, preferred consumables, fixture habits)

- Inspection routines that only one person remembers

- Code and documentation workflows (WPS/PQR basics, sign-offs, traceability steps)

You see the same pattern across job shops: one person becomes “the CNC guy,” and everyone else is locked out of the process.

What cross training looks like here is smaller than you think:

- Train a backup to handle standard material/library jobs and common nests.

- Create a “known-good” template pack (post settings, common materials, standard lead-ins, common part families).

- Document the top 10 “gotchas” (consumable wear signs, common pierce failures, how to zero, where scrap traps happen).

You’re not trying to turn a helper into your best programmer overnight. You’re trying to stop the entire shop from stopping when your programmer is sick.

3) Plan-release and status coverage (office-to-floor, not “admin stuff”)

In custom fabrication, a planning miss can be just as expensive as a bad weld.

Cross training should include at least one backup for:

- Job release/priority updates

- Updating statuses so everyone knows what’s actually done

- Customer date communication (so sales isn’t guessing, and ops isn’t surprised)

Reddit’s “skills matrix goes stale” discussion in r/LeanManufacturing nails the point: if your matrix isn’t used to enable real flexibility, it becomes “a pretty chart for auditors.” Real value is when it guides who can jump in where, and who should be next in line for training.

This is also where tools matter. Whether you do it in a spreadsheet or in EZIIL, the goal is the same: make it obvious who can release work, who can update progress, and who can cover those tasks when the usual person is out.

4) Cross training that respects pay and pride

This is the part a lot of owners miss: cross training is motivating only if it feels fair.

Machinists talk about this openly: cross training is great, but pay needs to keep up, otherwise you’re just training someone into more responsibility for the same money.

And the retention research backs up why this matters: “cross-training with opportunities for broad and challenging assignments” shows up as part of more sophisticated retention approaches, and younger workers in particular cite training and career opportunities as a big reason they stay.

So in practice:

- Be explicit about the “why” (less firefighting, fewer late nights, less hero culture).

- Tie new skills to something real: pay bands, lead opportunities, preferred work, or clear progression.

What the evidence says about cross training

1) Cross training is a proven way to handle “life happens” disruption

Operations research on workforce flexibility calls out internal worker uncertainty (like absenteeism) and day-to-day system fluctuations as core realities in manufacturing. Cross-training is one of the standard levers to stay productive when those disruptions hit.

And when demand mix changes (classic custom fabrication), research on cross-training specifically frames it as a way to cope with variable requirements, because more cross-training generally means more flexibility (with the tradeoff that it needs to be implemented intentionally).

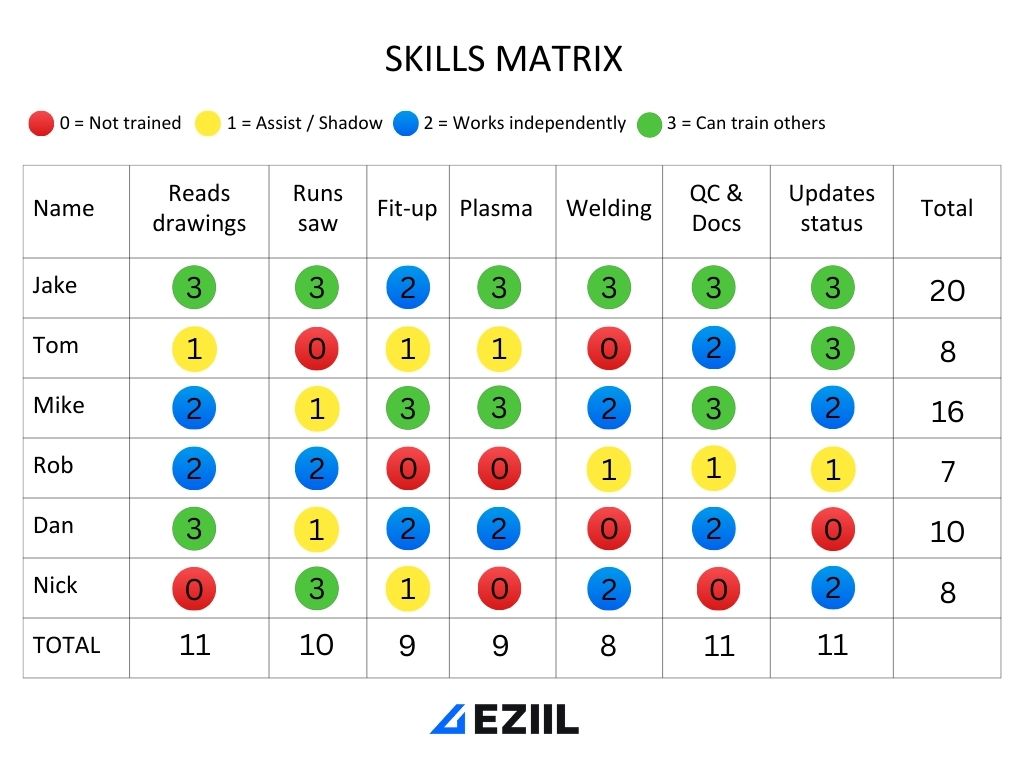

2) There’s a standard, shop-friendly tool for making it real: the Skills Training Matrix

Lean fabrication shops don’t treat cross training as a vague goal. They operationalize it with a Skills Training Matrix that shows required vs attained skills, and it includes the training schedule.

That matters because small shops usually think they know who can cover what… until the day they actually need it. The matrix forces the uncomfortable but useful truth: where you have a single point of failure, and where you already have depth.

3) Most manufacturers already do cross-functional training, and the biggest blocker is time

This is where the data gets refreshingly practical.

In the Manufacturing Institute’s training survey, cross-functional training is one of the most commonly used training approaches (reported by 82.3% of respondents).

The same survey also spells out why shops struggle to do it consistently: the top obstacles include interrupting work hours (74.1%) and scheduling (59.5%).

You’re not “behind” if you haven’t nailed cross training. The constraint is real. The solution is designing training that fits production, not pretending you’ll find a spare week.

4) Cross training shows up in serious retention programs (and younger workers care a lot about it)

The aforementioned retention research explicitly lists cross-training (alongside development plans and clear career paths) as part of more comprehensive programs to keep people. It also highlighted something shop owners feel but don’t always quantify: workers under 25 reported staying because of training and development (69%) and career opportunities (65%).

It’s safe to say that cross training is not only a scheduling tactic. It’s also part of how you keep good people, especially as experienced trades get harder to replace.

So the “why” is clear in both research and shop-floor reality. The real question (and the part most shops get stuck on) is: how do you build coverage without sacrificing output or burning out your best people?

How to implement cross training in a small custom steel fabrication shop

Step 1: Build a skills matrix that matches how fabrication actually works

A good skills matrix is not a HR spreadsheet. It’s a risk map. The concept is simple: required skills vs attained skills, plus the training schedule.

Build yours like this

Rows=people

Include shop + office roles that affect flow:

- detailing/engineering

- nesting/CAM

- saw/laser/plasma

- fit-up

- welding (MIG, TIG, FCAW, etc.)

- grinding/finishing

- coating/paint

- assembly

- loading/shipping

- planning/job release

- purchasing coordination

Columns=capabilities (not job titles)

For example:

- reads fabrication drawings confidently

- performs fit-up on complex assemblies

- runs saw safely and hits cut accuracy

- sets up and runs plasma

- welds structural assemblies to spec

- performs basic QC checks and documentation

- runs paint booth and understands cure constraints

- updates job status and notes in the system

Levels (keep it simple)

- 0 = not trained

- 1 = can assist/shadow

- 2 = can run standard work alone

- 3 = can train others

Then highlight any column where only one person is a 2 or 3. Those are your single points of failure.

Step 2: Pick the first 2–3 cross-training targets

Choose your first wave using three filters:

- Bottleneck step (where work piles up most often)

In many small shops: fit-up, welding, paint, and planning. - High-risk skill (only one person has it at level 2/3)

- Human risk (your “hero” is overworked, near retirement, or clearly burning out)

If you pick 2-3 targets that hit all three filters, you’ll feel results fast without turning this into a “training program” that dies in a month.

Step 3: Make training low-friction by using real jobs and small time blocks

The main enemy of your cross training system will most likely be time disruption. So design cross training around reality.

Here’s a format that works well for a 10-50 person custom fab shop:

- 1-2 hours/week per trainee, scheduled like a real job

- One trainer + one trainee (two max)

- Use real backlog work, not classroom sessions

- Define a finish line: “After 6 sessions, you are level 2 on saw for standard profiles.”

Then track progress back in the matrix every month.

Step 4: Put safety and quality guardrails in place (so cross training doesn’t create rework)

Cross training is not a free-for-all. When someone touches a new machine or process, safety and training requirements matter.

OSHA’s training requirements guidance emphasizes employers’ responsibilities around safety and hazard recognition.

In steel fabrication terms, that means:

- Do a basic task hazard review before a trainee runs equipment solo

- Use checklists for setup and shutdown

- Define what work a level-1 person can touch (and what they cannot)

- Require a quality sign-off step until someone is proven at level 2

This is how you avoid “cross training” turning into expensive scrap.

Step 5: Make it visible, so coverage becomes a normal planning habit

One reason cross training fails is that it stays in someone’s head.

Put the skills matrix where planning decisions happen. Make it part of your weekly production meeting.

If you’re running EZIIL Starter, you can tie this directly into how you already plan and execute work:

- plan capacity and spot workload conflicts in a visual resource view (MasterView)

- assign tasks to departments and keep instructions attached to the job

- let the shop floor log hours and update job status from mobile, so you see progress in real time

- compare planned vs actual hours to see where training is reducing overruns over time

That last one is underrated: cross training is not just “coverage.” It should improve predictability.

Step 6: Don’t burn your best people by accident

A common failure mode: cross training becomes “let’s pile more on the same reliable folks.”

Instead:

- Replace hours, don’t add hours. If someone trains for 2 hours, remove 2 hours of lower-value work that week.

- Explain the point clearly. The goal is fewer late nights and less firefighting.

- Reward skill growth. Even small recognition matters. Cross-training shows up in retention best practices because people want growth and a path, not just repetition.

Step 7: Measure success with shop metrics that actually matter

Pick 3-5 metrics and review monthly:

- on-time delivery (by job and by department)

- overtime hours and expediting events

- WIP age (how long jobs sit between steps)

- rework and NCR drivers

- variance between planned vs actual labor

If you’re using EZIIL’s time/operation tracking (mobile reporting + labour hour confirmation), you can get a clean view of where training is shrinking bottlenecks and stabilizing throughput.

common cross-training mistakes (and how to avoid them)

- Rotating too fast. People need repetition to become level 2.

- Training with no standard work. You want “consistent done right,” not “everyone does it their way.”

- Only training shop roles. In custom fab, planning and job release are often the real bottleneck.

- Not scheduling training time. If it’s optional, it disappears.

- Letting cross training bypass safety. New tasks need the right training and guardrails.