Shop floor scheduling

What is shop floor scheduling in steel fabrication?

Shop floor scheduling is the day-to-day sequencing and dispatching of work to each work center (today, this shift, this week). It answers: “What should this machine or crew run next?”

A common output is a dispatch list, which is a prioritized list of work orders or operations for a given work center, typically generated daily.

Master scheduling says what should happen over the next weeks. Shop floor scheduling is where that plan becomes real, one decision at a time.

Why shop floor scheduling matters in steel fabrication?

Steel shops lose days in the gaps between steps. Work sits “almost done” while the next station is unsure what to pull, or the crew starts something that is not ready and gets blocked.

Good shop floor scheduling:

reduces waiting and searching

prevents WIP explosions (too many jobs half-started)

improves on-time delivery by keeping the right jobs moving

makes priorities fair and transparent (not “whoever asked last”)

It matters even more in HMLV environments, where every job is different and the “default sequence” is rarely correct.

Best practices for for practical shop floor scheduling

1) Define “ready to run” rules

Before a job hits a dispatch list, confirm:

drawing revision is correct and released

material is available (or the missing items are known and planned)

prior operation is complete and parts are physically accessible

This prevents false starts.

2) Keep the priority rule simple

Pick 1-2 rules and stay consistent. Examples:

earliest ship date first, unless it starves the bottleneck

bottleneck-first (keep the constraint busy), then due date

The point is not perfection. The point is consistency.

3) Limit WIP on purpose

If every department has 20 jobs “in progress,” nothing flows. Set WIP limits by area, especially in fit-up and welding where jobs can get stuck.

4) Run a daily dispatch huddle

10 minutes is enough:

what is running now

what is next

what is blocked and who owns the unblock

This reduces the need for constant mid-day interruptions.

5) Capture blockers as data

Blockers are scheduling inputs. Track them:

waiting on material

missing info

rework/quality

machine downtime

Then fix the top 1-2 root causes.

6) Keep a small buffer before the bottleneck

The bottleneck should never be waiting for work. Keep a short, ready queue so it stays productive.

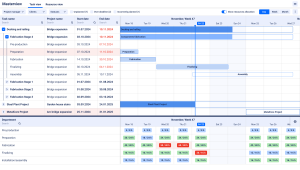

How EZIIL supports shop floor scheduling

Shop floor scheduling gets easier when the plan and the reality are visible in the same place.

EZIIL helps by:

making job status and ownership clear, so supervisors can see what is actually ready, not what someone thinks is ready

allowing quick updates and notes when something is blocked, so dispatch decisions reflect reality

supporting better handoffs between departments because tasks and phases are explicit, not implied

A common win: instead of chasing updates, supervisors spend that time removing blockers early, which is one of the fastest ways to improve OTD.