Production Routing

What is Production Routing?

Production Routing is the detailed sequence of operations and work centers that a job follows through the shop. It’s essentially the process plan for how raw stock transforms into a finished structure.

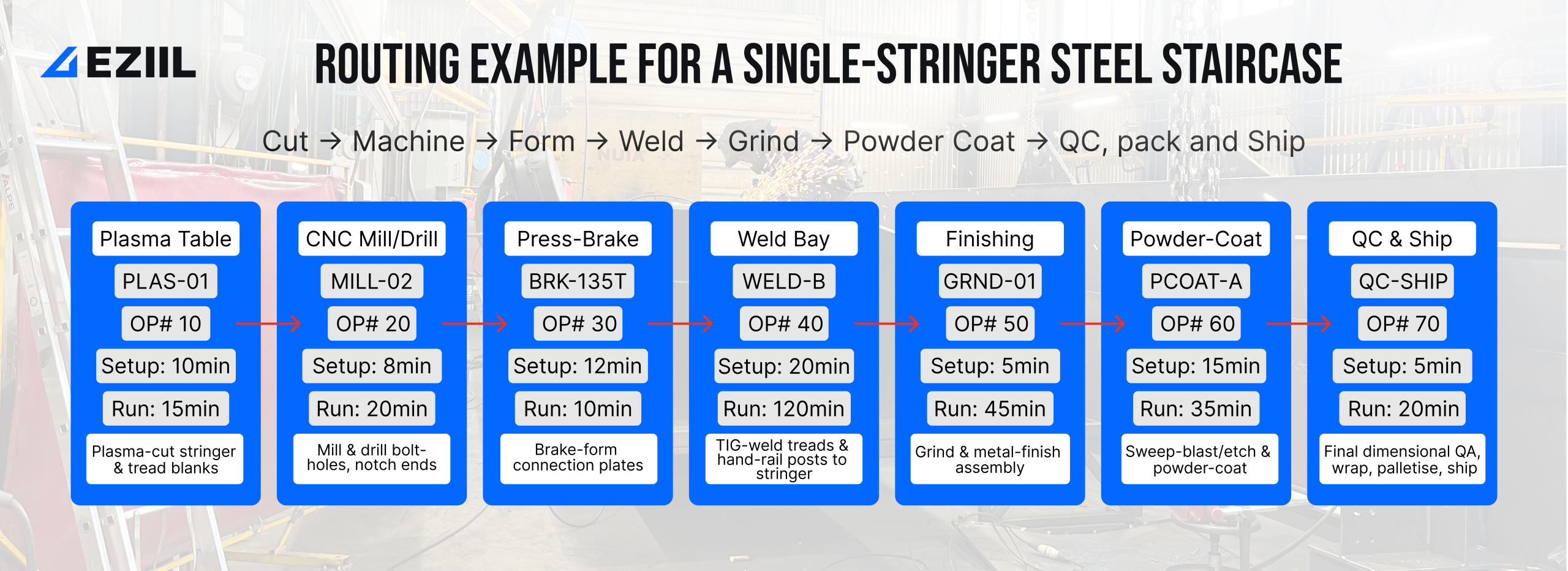

For example, a simple Production Routing in a steel fabrication shop could look like this:

Sawing → Drilling → Fit-up → Welding → Painting

A clear routing specifies each step’s machine or station, setup time, and cycle time.

In custom steel fabrication, routing is relatively static for common part types but must be tailored per project.

Effective routing lets a small shop schedule jobs realistically, prevent misrouting or bottlenecks (like two jobs fighting for the single CNC drill line), and calculate labor and machine loads for each project. It forms the basis of accurate scheduling and costing by standardizing how work travels through the shop.

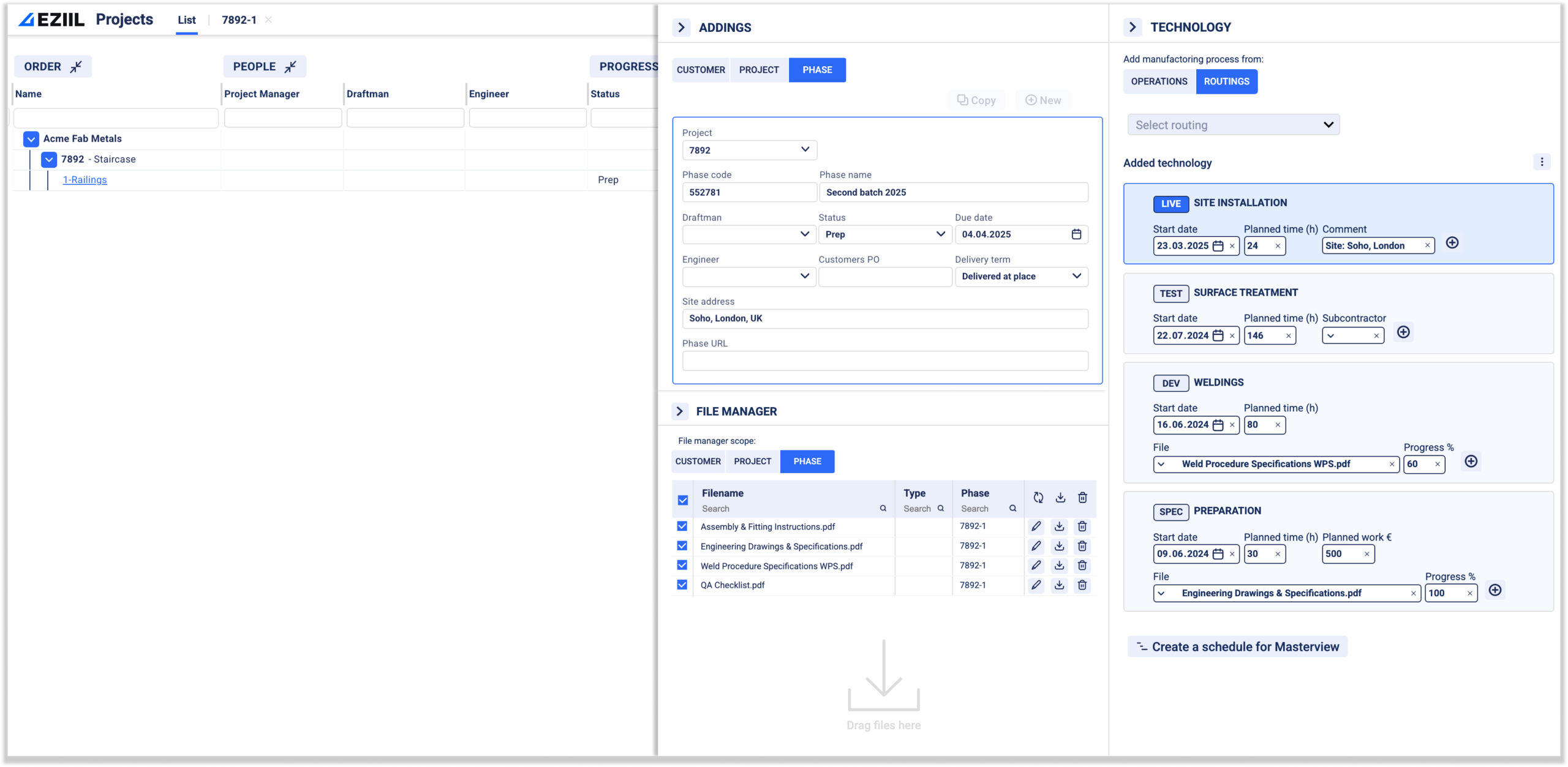

Below, you can see an example how production routing works in EZIIL software.