Manufacturing Execution System (MES)

What is Manufacturing Execution System (MES)?

A Manufacturing Execution System (MES) is software that monitors and controls production on the factory floor in real time.

You can think of MES as the link between your high-level planning (ERP/MRP) and the actual operations happening at each workstation.

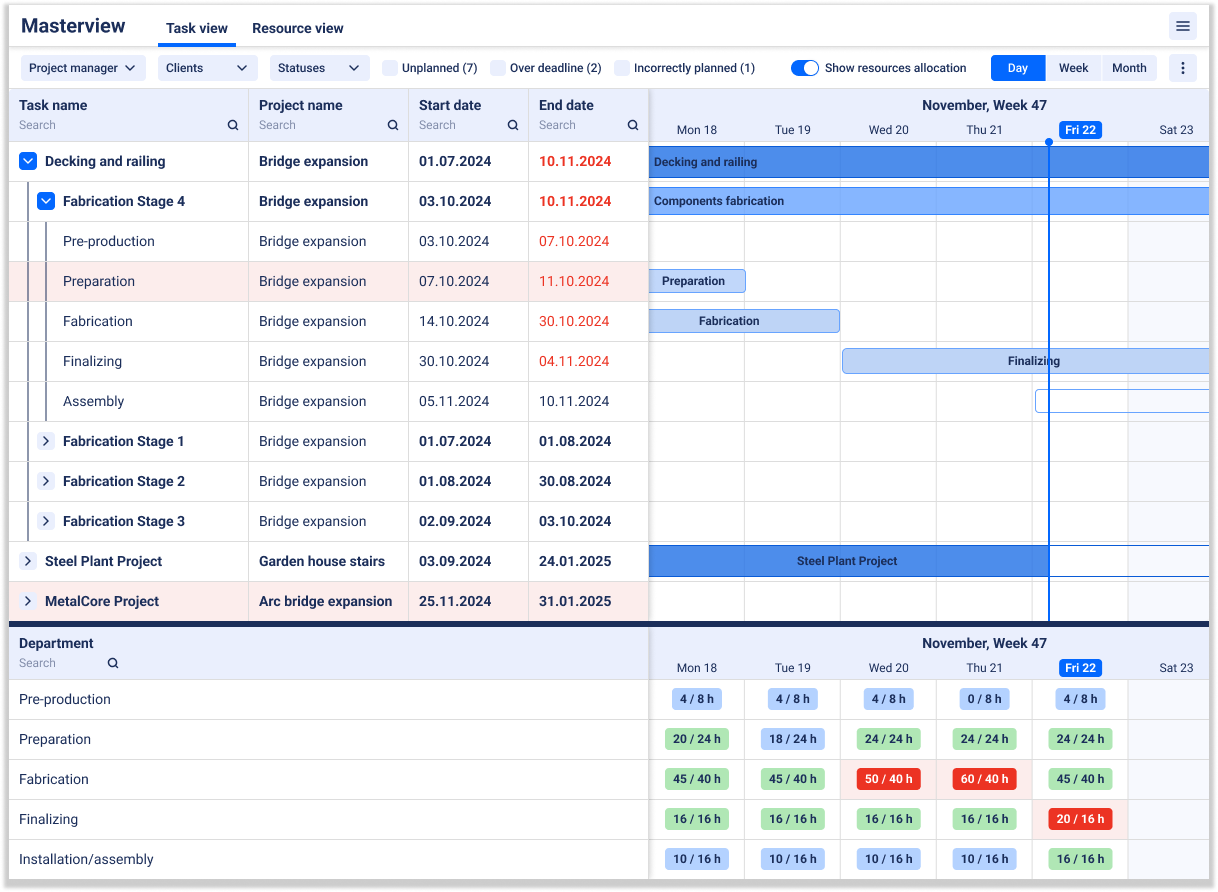

In a small fab shop, an MES might provide digital work instructions to the welders, track time and progress as jobs move through cutting/welding/painting, and record quality checkpoints and completions instantly. It gives managers a live view of work-in-progress, machine statuses, and output, enabling quick decision-making if, say, a machine falls behind or a quality issue arises.

A MES’ key functions often include dispatching work orders to the shop floor, collecting data from operators or machines (for example, a barcode scan when a step is finished), and enforcing quality processes (like preventing a job from moving forward if an inspection is not passed).

By implementing even a basic MES module, small fabricators can eliminate paper travelers, get real-time production data (for example, to see if a job is at risk of delay and intervene), and maintain better traceability (which is valuable for certified quality systems).

As opposed to expensive and complex ERP/MRP systems, modern cloud-based MES solutions, such as EZIIL Starter, are scalable, affordable and accessible to smaller manufacturers.