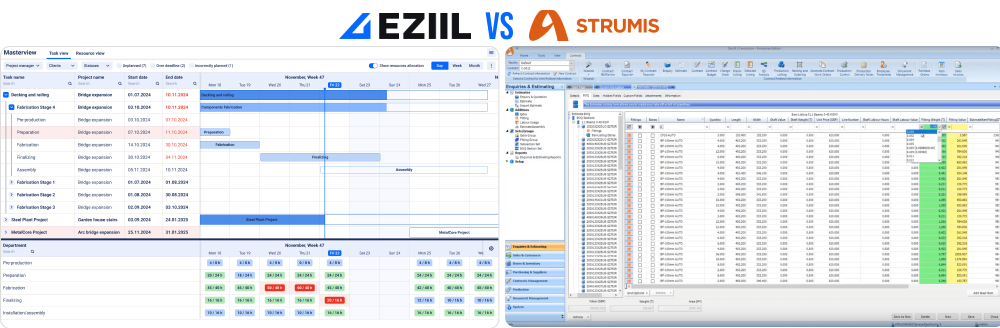

Below you’ll find a side-by-side comparison of StruMIS vs EZIIL, comparing the factors that matter most to small custom steel fabricators, such as cost, learning curve, scheduling clarity, traceability, and the hidden “gotchas” that can stall production for weeks. Use it as a quick gut check to find the perfect project management and execution tool for your steel fabrication shop.

StruMIS vs EZIIL at a glance: comparison table

| What matters to small shops | EZIIL Starter | StruMIS | Why is it important? |

|---|---|---|---|

| Up-front cost and cash flow | Starting from €90/month base subscription, cancel anytime. | Starting from €2300 per licence as a one-time fee + annual support fee of €460. Can cancel support at any time and program continues to operate. Payment plan removes any capital expense. | Monthly subscription model removes capital-expense shock and preserves working capital. |

| Implementation time | Weeks. Guided onboarding, minimal IT work. Typical go-live in 4 weeks. | Weeks. Guided onboarding with assistance with eLearning. Typical go-live in 8 weeks. | Faster go-live means quicker ROI and less production disruption. |

| Ease of use for shop floor | Drag-and-drop Gantt, mobile start/stop app. Non-tech workers can adapt in a day. | Simple and modern UI, no install required. Training limited to only 4 hours – Strumis Vision. | Lower training overhead keeps jobs moving and workers engaged. |

| Scheduling and real-time visibility | MasterView auto-detects bottlenecks, live completion progress %, override allowed. | Robust executive dashboards offer a simple and effective view of progress | Instant clarity beats hidden data when juggling many small jobs. |

| Specialisation | Built specifically for project-based metal fabrication (cut lists, welding stages, traceability). | Flexible across multiple manufacturing sectors from steel to timber. Barcoding included. CAD and CNC machinery integration provides full BIM methodology. | EZIIL handles mixed custom work. StruMIS excels in high-tonnage structural steel. |

| Scalability and modules | Add BOM, purchasing, inventory when ready. Only pay for what you’re actually using. | Can start with STRUMIS Advance, grow to full STRUMIS Fabricator as your business expands. | Start lean, expand when processes mature to keep momentum and ease into new processes. |

| Offline resilience | Cloud-based. Mobile app caches shop-floor data and syncs when online. | Traditionally on-premise means no internet failure risk. On-line hosting optional. | Cloud + cache reduces risk during internet hiccups. |

| Accounting and third-party tools | Exports to QuickBooks/Xero. API for other apps. | Accounting module included. Additionally exports to 3rd party programs. | Best-of-breed approach keeps finance independent. |

| Support culture | Direct access to EZIIL fabrication experts for support. Feature requests accepted. | Global reseller network and support. Structured ticketing. Enhancement requests accepted. | Small shops often value hands-on, guidance from industry experts. |

Eziil Starter – All-in-One Custom Steel Fabrication Project Management

EZIIL Starter is a cloud-based Manufacturing Execution System (MES) and project management tool built specifically for custom metal fabrication shops. It guides users through all project phases: Prepare, Plan, Report, Analyze. All in one platform.

Key jobs EZIIL addresses include:

- Project planning and scheduling: Visual drag-and-drop Gantt scheduling of fabrication phases (e.g. cutting, welding, painting) with resource capacity planning. EZIIL auto-detects bottlenecks and even offers auto-scheduling based on available resources.

- BOM (add-on module) and document management: Centralizes bills of materials (BOMs) and operations, drawings, files, and custom data for each project. This ensures all departments work off the same, up to date information at all times.

- Real-time shop floor tracking: Provides a live task queue for workers and mobile app reporting so fabricators can log progress and labor hours on the fly. Management can see percent-complete and status of each task or component in real time (no more hunting through paper updates).

- Analysis and cost control: Tracks planned vs actual hours and provides an analysis on project profitability and performance. This helps refine future quotes and identify recurring inefficiencies.

- Communication and team alignment: Assigns tasks to departments or individuals with all instructions attached, so everyone knows what to do. It supports role-based access (for example, project managers vs shop workers). All updates are consolidated, replacing the “endless spreadsheets, pen-and-paper notes, and scattered communication” many small shops struggle with.

Who is EZIIL built for and what are its Use cases?

EZIIL is specifically designed for small-to-mid sized steel fabrication companies that manage custom steel projects (like staircases, small bridges, architectural metalwork, industrial equipment, etc.) and are moving off of disconnected tools like Excel or paper. These are typically shops up to 10-50 employees who find large ERPs overwhelming.

EZIIL is the easiest first step into digital project management for steel fabricators that have outgrown manual methods (Excel, pen and paper, whiteboards, etc.) but can’t afford a complex ERP implementation.

Use case examples:

- A 20-person structural steel fabricator that currently uses Excel for scheduling and folders of drawings on a server. They need real-time insight into fabrication status and a way to coordinate office and shop teams better.

- A job shop making custom sheet metal assemblies who struggles with manual job tracking and frequent rush changes. EZIIL helps them see bottlenecks and manage change orders in one place.

- Any fab shop pursuing EN 1090 certification or similar. EZIIL’s traceability features (logging who did what, storing QC images, etc.) support higher execution class jobs, which is usually beyond the capability of spreadsheets.

EZIIL’s Features and Capabilities

EZIIL provides end-to-end support for steel fabrication project workflows. From quoting, BOM and bill of operations creation, scheduling and capacity planning, shop-floor data capture, through to delivery. It includes quality/compliance tracking (supports EN 1090 EX2/EX3 standards for traceability in structural steel), and reporting dashboards.

EZIIL’s Pricing

EZIIL is offered as a monthly subscription with a base starting at €90 per month (for up to 15 users).

EZIIL’s pricing is modular, so you can start with core planning and add modules as needed, rather than paying for an entire ERP suite upfront. This makes it budget-friendly for small steel fabricators, as there are no large upfront license fees, and you can cancel anytime if needed. (By contrast, something like StruMIS might start at tens of thousands of euros upfront.)

Implementation and Onboarding

EZIIL Starter is meant to be the first step into digital project management for metal fabrication, and is designed accordingly. It’s lightweight, intuitive, user-friendly and requires minimal learning curve.

EZIIL excels in quick, flexible adoption. No heavy IT effort or long downtime, unlike large ERP/MRP packages that can grind a small shop to a halt for months during implementation. EZIIL can be up and running in weeks.

EZIIL’s Pros

- Metal fabrication focus: Purpose-built for project-based fabricators, so it handles things like multi-phase jobs and custom BOMs intuitively.

- Ease of use: Very intuitive interface and simplified workflow for complex tasks. Users report that even shop-floor workers can adapt quickly with minimal training.

- Comprehensive visibility: Combines planning, scheduling, and tracking. Giving the users real-time production overviews and progress updates at a glance. Eliminates the need to reconcile data from separate tools.

- Collaboration and communication: Keeps all project info (drawings, notes, budgets, schedules) in one place accessible to all departments, which greatly improves team alignment.

- Continuous improvement: Provides “plan vs reality” reports on hours and costs, so you can identify inefficiencies and refine your processes and quoting accuracy over time.

- Scalable and modular: No need to over-invest. You can add modules when ready. Also, it’s cloud-based and scales as you grow, without heavy IT infrastructure.

EZIIL’s Cons

- Requires Internet/cloud: As a cloud solution, if your internet goes down, the system is inaccessible.

- Initial setup and customization: It’s not plug-and-play. EZIIL’s team assists in configuring the system to your shop’s needs (data migration, custom fields). This service ensures a good fit but means an upfront time investment of a few weeks. Some very custom workflows might need further tailoring by EZIIL.

- Limited financials: EZIIL Starter focuses on MES/project management. It doesn’t try to replace full accounting systems. You’d still use QuickBooks or similar for detailed financial accounting (though EZIIL can export needed data). For some, this is a pro (use best-of-breed in each area), but companies seeking an all-in-one ERP including accounting might see this as a gap.

What do EZIIL’s Customers Say

EZIIL’s customer feedback is strongly positive among small fabrication shops. Many see it as “highly beneficial” for digitizing and gaining control of their process. Users especially like that EZIIL guides them step-by-step through implementation and continuously incorporates their feedback and have states that it’s a “solution that evolves with their needs”.

Fabricators often mention how before EZIIL they were “wrestling with endless spreadsheets” and constantly firefighting issues, but after adopting EZIIL, they report improved on-time delivery and less chaos on the shop floor.

One reviewer sums it up: “EZIIL remains a highly beneficial tool for fabrication businesses seeking to optimize their manufacturing process through digitization”.

What Makes EZIIL the Perfect Option for Steel Fabricators

For small fabricators, EZIIL offers a good “just right” solution. It’s more powerful and integrated than spreadsheets or basic MRPs, but far simpler and more affordable than heavyweight fabrication ERPs.

Unlike generic MRPs, it was designed around metal fabrication jobs, so it natively handles things like cut lists, welding stages, and project-based costing. And unlike older industry software, it’s cloud-based and subscription-priced, reducing risk. It’s basically a targeted answer to the exact “jobs to be done” small fabricators have: scheduling the shop, knowing the status of every job in real time, managing BOMs and drawings, coordinating production, and analyzing job profitability. These are precisely the areas where status quo tools fall short and where ERPs either excel but at high cost or are decent but not specialized.

StruMIS – Fabrication Management System for Structural Steel

StruMIS is a steel fabrication management software primarily used by mid-size and large structural steel fabricators and construction steelwork companies. It was historically adopted by many bigger fab shops (50+ employees or high tonnage output) to integrate their entire production process. Smaller steel fabricators (20-50 employees) use StruMIS as well in the agricultural, equestrian, building and transmission towers sectors. Essentially, StruMIS is built for fabricators who need robust tracking of thousands of steel parts, often for large building projects, and who can dedicate time and resources to a complex system.

StruMIS’ Features and Capabilities

StruMIS is an end-to-end MRP/ERP for steel fabrication covering:

- Estimating and Tendering: Quickly create quotes and bids by importing BOMs from CAD drawings or spreadsheets. It can do detailed cost breakdowns and what-if analysis for bids.

- Material Management and Procurement: Automated purchasing and inventory management for steel sections, plates, and consumables. It optimizes stock by tracking remnants and offering nesting to minimize waste.

- Project/Contract Management: Track projects from contract award through completion, linking estimated vs. actual costs on jobs. It has cost control features for comparing budgeted vs actual labor and material on each job phase.

- Production Control and Scheduling: StruMIS monitors fabrication progress for each component and assembly using customizable workflows. It includes a 3D model integration, which let’s you import models from BIM detailing software and use that for production tracking. It has built-in CNC machine integration and a StruCNC module (CAM) for editing NC code. Barcoding is heavily used: StruMIS offers mobile scanning apps (both online/offline capable) to update part status through the shop.

- Quality and Traceability: Traceability of each piece: which stock it came from, welders who worked on it, coatings, etc. This helps fabricators meet standards like EN 1090 or ISO, by maintaining inspection records and material certs.

- Integrations: StruMIS interfaces with virtually all major 3D steel detailing/BIM software and with accounting systems (for invoicing and financials). It’s often part of a suite with model management: e.g., detailers model the structure, StruMIS imports the BOM and drawing data, then manages production.

- Reporting: Custom report builder for everything from production throughput to costing to inventory valuation. Many users generate project status reports or fabrication progress reports for management or clients.

StruMIS aims to be the central MIS (Management Information System) for a steel fabrication company, tying together departments from estimating to purchasing to the shop floor.

StruMIS’ Pricing

StruMIS is traditionally sold as an on-premise licensed software (Windows-based) with modules for additional security. Pricing is per licence and bought in perpetuity.

While exact prices require a consultation, a typical package for a small-medium shop (around 10 users with core modules like estimating, inventory, production, and nesting) starts around €9000 upfront (license fee) plus annual maintenance. Larger configurations can cost significantly more. This upfront cost can be a barrier for small firms.

The maintenance/support contract is usually 15-20% of license cost yearly (optional after first year).

There have been indications of subscription models in recent years, but the dominant model is still license + maintenance.

Bottom line: StruMIS is a high-end investment. Fabricators often justify the investment by ROI in scrap reduction and improved efficiency, but for an owner-operated 20-person shop, the cost may be prohibitive.

Who is StruMIS built for and what are its Use cases?

StruMIS positions itself as a comprehensive solution to “streamline the steel fabrication process from initial bid to final bolt”. They highlight features like BIM integration, material optimization, and real-time tracking as ways to save time and money.

StruMIS is ideal for a dedicated structural steel fabricator or industrial contractor that:

- Fabricates a high volume of steel components (beams, columns, trusses, plate work) often tied to 3D models.

- Needs rigorous material tracking (for example, buys steel bars and sheets in bulk, needs to optimize material usage and trace every piece to its material test and certificate).

- Has CNC equipment (saws, drills, plasma cutters) to integrate, and possibly does their own detailing in-house.

StruMIS’ Pros

- Industry-Specific Functionality: Handles steel fabrication needs out-of-the-box. BOM import from CAD, parametric assemblies for common connections, tracking of each piece through cutting, welding, painting, etc.

- Integration and Traceability: Excellent integration with BIM/detailing software and CNC machines. This means fewer errors from manual data entry. It provides full traceability of materials and components, which is crucial for quality control and certifications.

- Automation and Productivity: Many processes (like generating purchase orders from material lists, or updating part status via barcode scan) are automated, improving productivity. Users report reduced errors and faster throughput once StruMIS is properly implemented.

- Comprehensive Reporting: Offers powerful analytics, such as cost breakdowns, efficiency reports, etc. You can monitor budget vs actual at any point (though as noted below, some find labor cost tracking to have gaps).

- Built-in Barcoding: Includes barcoding as standard at no extra cost.

- Multi-Facility: Supports super-sized fabricators and group companies.

StruMIS’ Cons

- Complexity and Learning Curve: StruMIS is a complex, high-end system, which can challenge first-time users. Implementing it fully is a major project: including data migration, staff training, and possibly customizing workflows. One independent review notes “implementation is complex and requires a steep learning curve,” adding risk since the initial investment is significant. A common refrain is that it may take many months before the system is fully operational and people are comfortable.

- Initial Setup Time and Cost: Getting StruMIS tuned to your business (setting up all BOM templates, machinery settings, cost codes, suppliers, customers etc.) takes time. However, the technical support team customises each implementation for you. The ROI may not be immediate. The setup can be lengthy before you start reaping benefits.

- High Cost for Small Shops: The software’s depth comes at a price, both in money and in needed usage to justify it. The upfront license fee plus optional ongoing fees and possibly hardware (servers, etc.) is a big hurdle if your revenue is, say, a few million USD or less.

- Legacy Technology: StruMIS has been on the market a long time (since the 1980s). It’s typically on-prem Windows software, cloud access or web interfaces are not its strong suite. Upgrades to new versions require a current support and maintenance contract be in position. In contrast, newer steel fabrication management tools push updates automatically.

- Limited Budgeting vs Actuals Tracking: Independent reviewers note difficulty in differentiating between labor hours and machine hours in job costing, and lack of granular budget-vs-actual dashboards. One review explicitly said “when it comes to budget vs actuals it’s sadly bad – there is no way to check or differentiate between labor hours and machine hours”.

- No Native 2D Takeoff: There’s no built-in 2D drawing takeoff for estimating. Meaning, if you have PDF drawings (not a BIM model), StruMIS doesn’t natively let you measure/count on them. You’d need an external takeoff tool or to manually key in BOM lines. This works well for users who plan to import data from 3D models or spreadsheets provided by detailers/engineers.

Overall, StruMIS is respected as a powerful but heavy solution with price tag to match that.

STRUMIS VS EZIIL: Which one is better for small custom steel fabricators

For small, project-diverse fabricators, EZIIL’s simplicity and lower cost are huge advantages. EZIIL can be implemented in weeks, and you won’t “grind your entire shop to a halt” during rollout. Many small shops simply do not have the bandwidth to train a whole team on StruMIS or to hire a full-time admin for it.

Additionally, EZIIL’s interface is more modern and easier to learn. An owner or foreman who is not extremely computer-savvy can navigate it, whereas StruMIS might require more intensive training (as the “steep learning curve” con notes).

Cost-wise, EZIIL’s monthly subscription is much friendlier to a small business cash flow than a big upfront StruMIS license (unless opting for a 5-year payment plan). And if the shop does varied fabrication (some structural, some miscellaneous metals, perhaps some machining or custom work) then EZIIL’s flexibility to handle any project structure might be better.

If the shop is highly specialized in structural steel, they might want to opt for StruMIS for its rich features and industry acceptance. StruMIS includes more of the financial side (for example, invoicing, valuation) within the system, whereas EZIIL focuses on operations and would integrate with accounting software for financials.

To sum it up, StruMIS is a high-end solution that may not be cost-effective for smaller fabrication companies that do different types of projects. Many such companies will find that EZIIL covers their needs in a lighter, more user-friendly manner.