NCR (Non-conformance rate)

What is NCR (Non-conformance rate) in steel fabrication?

Non-conformance rate (NCR) is a quality KPI that tells you how often work fails to meet requirements.

In a steel fabrication context, that usually means a part, weld, assembly, or documentation step that triggers rework, repair, scrap, or a formal nonconformance record.

Why NCR matters for custom steel fabricators

In high-variation work, quality issues don’t just “cost a bit of material”.

They:

Steal capacity (rework hours push out planned work)

Hit on-time delivery (OTD) (a late fix often becomes an expedite)

Reduce margin (the quote assumed first-pass success)

Create downstream chaos (one missed fit-up or weld issue can block paint, shipping, install)

How to measure NCR

Pick a definition that fits your shop and stick to it for trend tracking.

Option 1: By items/inspections

NCR % = (Nonconforming items ÷ Total items inspected) × 100

Option 2: By jobs

Job NCR % = (Jobs with at least 1 nonconformance ÷ Jobs completed) × 100

Option 3: By effort (great for job shops)

Rework hours % = (Rework hours ÷ Total labor hours) × 100

Tip: in High Mix Low Volume (HMLV)/Make to Order MTO, “units” can be misleading, so many shops prefer job-based or hours-based NCR.

Best practices to reduce NCR

Define “done” clearly at each step (fit-up, tack, weld, drill, finish, pack). Ambiguity creates repeat mistakes.

Add lightweight quality gates where fixes are cheapest (pre-weld checks, first-article on repetitive families).

Use reason codes (fit-up, drawing revision, wrong material, weld defect, missing hole pattern). Then run a simple monthly Pareto.

Close the loop into quoting: if handrails keep burning 12% extra hours in grinding and rework, update the “reference job” assumptions.

Treat repeat NCRs as a system issue, not a person issue: unclear drawings, missing tolerances, rushed releases, or bad handoffs are the usual culprits.

EZIIL best practices

Reducing NCR is mostly about clear instructions, tight handoffs and fast visibility.

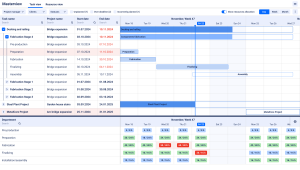

If you’re using EZIIL’s steel fabrication software make sure to:

Keep each project’s drawings, notes, and decisions EZIIL’s system, so the shop isn’t guessing which revision is correct.

Use task ownership and statuses to prevent “I thought you had it” moments between engineering, fabrication, and finishing.

Track plan vs. actual hours/materials so quality-related overruns show up while you can still act, not after the job is shipped.

Log issues as they happen (comment + attachment) to build a simple “what went wrong” trail for after-action reviews.