Productivity and efficiency are two essential components of a successful manufacturer. Those shops with routers, lasers, and plasma cutters depend on these machine tools to provide speed and quality with minimum waste.

“Nesting” is one of the terms you’ll frequently hear in connection with laying out irregular-shaped parts on a flat sheet of material, whether sheet metal, wood, plastic, or even cloth. It’s the cornerstone of every shop looking to save time and material while gaining a competitive edge.

Utilizing the best nesting software is key to optimizing these processes and achieving superior results.

What is nesting program?

Nesting has been compared to packing a suitcase in that you place your items into it with the least amount of wasted space. Similarly, the goal of nesting and sheet metal nesting program is simple: produce as many parts as possible from as little material as possible and do it in as little time as possible. Optimized layout of the parts reduces material waste and enhances the finished goods production, therefore maximizing profits.

CNC shops use automated sheet metal nesting program with mathematical algorithms to optimally arrange parts for cutting within a sheet of material. The nesting process typically occurs right after the design phase and before machining, eliminating hours in the overall project and boosting profitability.

The nesting process begins when a designer draws a part using computer-aided design (CAD) software. The sheet metal nesting program is a form of computer-aided manufacturing (CAM), and it imports the geometry from the CAD file, using it to create the nests.

The files are then prepared for machining by applying the cutting parameters. And in the last step, the software automatically creates the nest, or, in some cases, the user does it manually. Automatic sheet metal nesting program rotates and fits the parts for optimal utilization while accounting for various combinations of parts, plates, and nesting approaches to produce the best results.

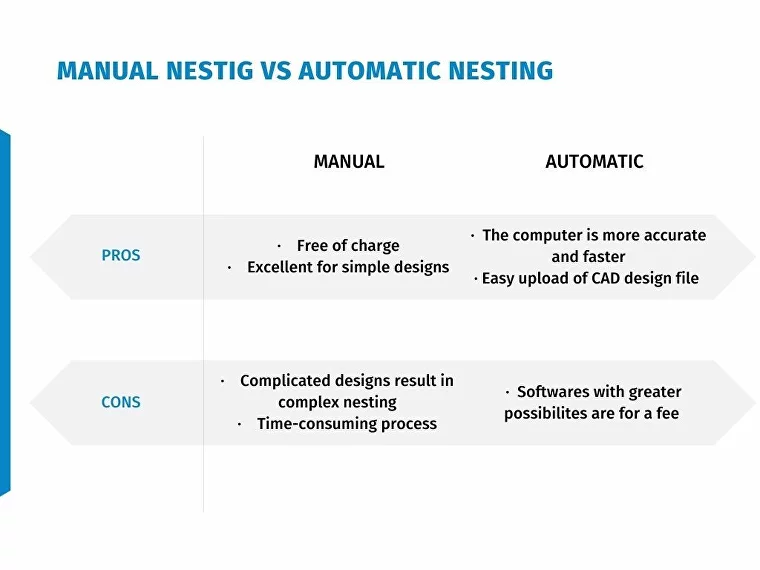

Manual nesting vs. automatic nesting

The two options for nesting are manual or automatic. Here is how they compare:

Manual nesting: Manual nesting involves a trial-and-error process of positioning parts by hand until they fit in the least amount of space. By using a manual nesting strategy upfront, you have a better chance of placing pieces to take advantage of opportunities such as shared lines, so you can see manual nesting works better for straight lines and simple designs.

Manual nesting pros:

· Free of charge

· Excellent for simple designs

Manual nesting cons:

· Complicated designs result in complex nesting

· Time-consuming process

· The computer is more accurate (and faster!)

Automatic nesting software: Let’s face it, computers are fast and efficient, so automated nesting software will typically configure the parts quickly and with a minimum of wasted material.

Nesting tools make it easy to upload a CAD design file and allow the nesting program to arrange the pieces on the sheet. Depending on the nesting software, you might be able to combine parts from multiple files.

Although CNC nesting software can be expensive, the possible savings in increased production and minimum material waste far outweigh the initial software costs.

Which are the ten best brands of automatic nesting software?

Choosing the best of any product is a subjective undertaking, and nesting software is no exception. However, we have attempted to arrive at this list with as much objectivity as possible, so here goes:

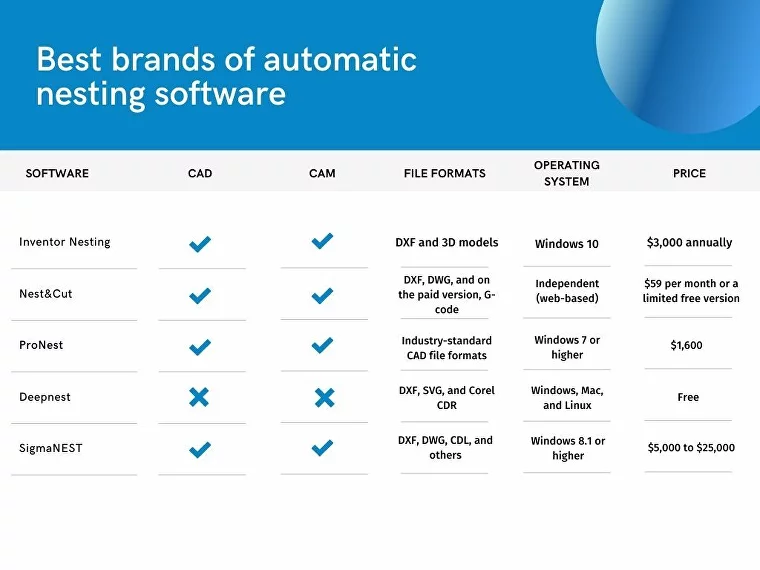

1. Inventor Nesting

Inventor Nesting is part of one of the leading CAD companies, Autodesk. It can help you optimize your yield from flat stock, reducing costs and enhancing efficiency. It exports 3D models or DXF™ files of the completed nest for cutting path generation, and it will compare the efficiency and costs associated with various nesting studies to maximize job profitability.

Features:

· CAD: Yes

· CAM: Yes

· File formats: DXF and 3D models

· Operating system: Windows 10

· Price: $3,000 annually

2. Nest&Cut

Nest&Cut is powerful web-based nesting software capable of re-nesting, order generation, multiformat nesting, inside-part nesting, parts cleaning, and much more. It does not require a high-performance computer to run the program since all the processing occurs on the server-side.

Although Nest&Cut is paid software, there is a free version with limitations to exporting files in DXF or DWG file formats. With the paid version, you can export designs in G-code file format, which most laser-cutting nesting software accepts.

Features:

· CAD: Yes

· CAM: Yes

· File formats: DXF, DWG, and on the paid version, G-code

· Operating system: Independent (web-based)

· Price: $59 per month or a limited free version

3. ProNest

ProNest allows you to nest your design manually or let ProNest do it automatically. The program targets the metal fabrication industry and supports plasma, oxyfuel, and waterjet. Other features include plate inventory, work order processing, management reports, and more. You get unlimited technical support and training with ProNest and won’t pay for future software updates.

Features:

· CAD: Yes

· CAM: Yes

· File formats: Industry-standard CAD file formats

· Operating system: Windows 7 or higher

· Price: $1,600

4. Deepnest

An open-source nesting software marketed toward hobbyists, Deepnest does not have editing features. Still, it imports your files and arranges your parts to reduce the cutting time and material waste. It automatically merges common lines and puts smaller parts inside larger cavities. An excellent entry-level nesting tool!

Features:

· CAD: No

· CAM: No

· File formats: DXF, SVG, and Corel CDR

· Operating system: Windows, Mac, and Linux

· Price: Free

Book a 60-minute demo to see

how eziil mrp solution works for you

5. SigmaNEST

SigmaNEST is a versatile industrial-grade nesting software appropriate for shops that have multiple cutting machines, including lasers, waterjet cutters, and plasma cutters. It is compatible with most 3D and 2D CAD tools and has modules beyond laser cutting, such as sheet metal bending, tube cutting, and punching.

Features:

· CAD: Yes

· CAM: Yes

· File formats: DXF, DWG, CDL, and others

· Operating system: Windows 8.1 or higher

· Price: $5,000 to $25,000 depending on the modules purchased

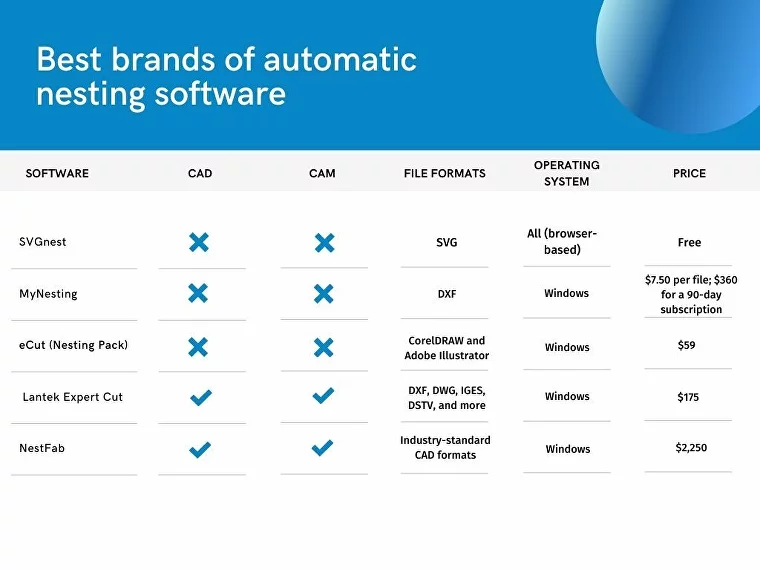

6. SVGnest

SVGnest is open-source web-based software that is available for free. It requires the internet for the software to load and process, but because it is web-based, it is OS-independent and runs on most devices with a web browser.

SVGnest is a relatively simple tool that uses the same nesting algorithm as Deepnest. It doesn’t require installation; merely upload the SVG file and hit “Start Nest,” When it’s finished, you can download an SVG file ready for cutting.

Features:

· CAD: No

· CAM: No

· File formats: SVG

· Operating system: All (browser-based)

· Price: Free

7. MyNesting

MyNesting software can be installed on systems running Windows OS, and although it is a paid service, it has more features than a free nesting program but doesn’t cost as much as the expensive industrial brands. Because of its unique pricing plan, you’ll pay only for what you use, making it ideal for individuals and small businesses who occasionally need nesting software.

Features:

· CAD: No

· CAM: No

· File formats: DXF

· Operating system: Windows

· Price: $7.50 per file; $360 for a 90-day subscription

8. eCut (Nesting Pack)

eCut (nesting pack) is a paid plug-in software enabling you to do nesting operations on CorelDRAW and Adobe Illustrator software. One benefit of eCut is you can try this software in “test mode” for four days using all the software functions. You will need the internet to activate the software because it generates the software unlock code by crosschecking the activation key and system ID.

Features:

· CAD: No

· CAM: No

· File formats: CorelDRAW and Adobe Illustrator

· Operating system: Windows

· Price: $59

9. Lantek Expert Cut

Lantek Expert Cut is an industrial-level nesting software designed mainly for laser-cutting metal sheets in an industrial setting. It offers a combination of automatic and manual tools, providing a flexible process. It may occasionally require internet access to perform updates and some authentications.

Features:

· CAD: Yes

· CAM: Yes

· File formats: DXF, DWG, IGES, DSTV, and more

· Operating system: Windows

· Price: $175

10. NestFab

The last nesting software we will review is among the best and most expensive. NestFab is an excellent automated product offering many useful features, such as an interactive CAD importer and complete control over quantities, sheet size, and part rotation. Also, it has full automation processes enabling you to produce nested parts around the clock.

Features:

· CAD: Yes

· CAM: Yes

· File formats: Industry-standard CAD formats

· Operating system: Windows

· Price: $2,250

Conclusion

In summing up, the role of nesting software in enhancing the efficiency of manufacturing processes, particularly those involving laser cutters and plasma cutters, is profound. This software, armed with key features designed to optimize resource utilization, acts as a catalyst in transforming raw material into precision-cut parts.

Laser cutters, known for their precision, versatility, and ability to produce intricate shapes, have become indispensable tools in various industries. However, when combined with nesting software, the capabilities of these laser cutters are significantly amplified. The software’s algorithms help to map out the most efficient cutting paths, thereby minimizing waste and maximizing the use of each piece of raw material. This combination of laser cutting technology with smart, resource-optimizing software has led to an increase in production efficiency and a decrease in manufacturing waste.

Similarly, plasma cutters, known for their ability to handle thick, heavy materials with ease, also benefit greatly from nesting software. The optimization of cutting paths allows these robust machines to operate at higher speeds, reducing processing time and boosting productivity.

Moreover, the software is not just limited to cutting processes. Laser engraving, a method used to etch or imprint designs onto surfaces, can also be optimized with the use of nesting software. By determining the most efficient layout for engraving, the software ensures that there’s minimal waste of raw material, leading to a more sustainable and cost-effective operation.

The key features of nesting software, including raw material optimization, cutting path planning, and engraving layout, are driving the future of manufacturing. They enhance the capabilities of laser cutters and plasma cutters, leading to increased efficiency, reduced waste, and cost savings.

In essence, the fusion of advanced cutting technologies like laser cutting and plasma cutting with smart nesting software is a testament to the technological advancements in the fields of mechanical engineering and product design. By capitalizing on these innovations, manufacturers can increase their productivity, reduce their material waste, and ultimately create more sustainable operations.

In the end, whether it’s laser cutting, plasma cutting, or laser engraving, the optimization provided by nesting software is invaluable. It’s not just about enhancing the functionality of laser cutters and plasma cutters – it’s about paving the way for a future where resources are used more efficiently, processes are streamlined, and sustainability is at the heart of manufacturing.