Steel Fabrication ERP software for make-to-order shops

EZIIL Steel Fabrication ERP Software add-on modules include Bill of Materials, Procurement, Inventory, Shop Floor Control, Machine and Resource Planning, Subcontractors, Shipments, Invoicing, Analytics, EN 1090 Traceability all in one connected system.

- Real-Time Master View for Capacity Planning and Production Info

- Advanced BOM and Engineering Data

- Shipments and Deliveries

- EN 1090-2/EX2-EX3 Compliance and Certificate History

- Purchasing Management

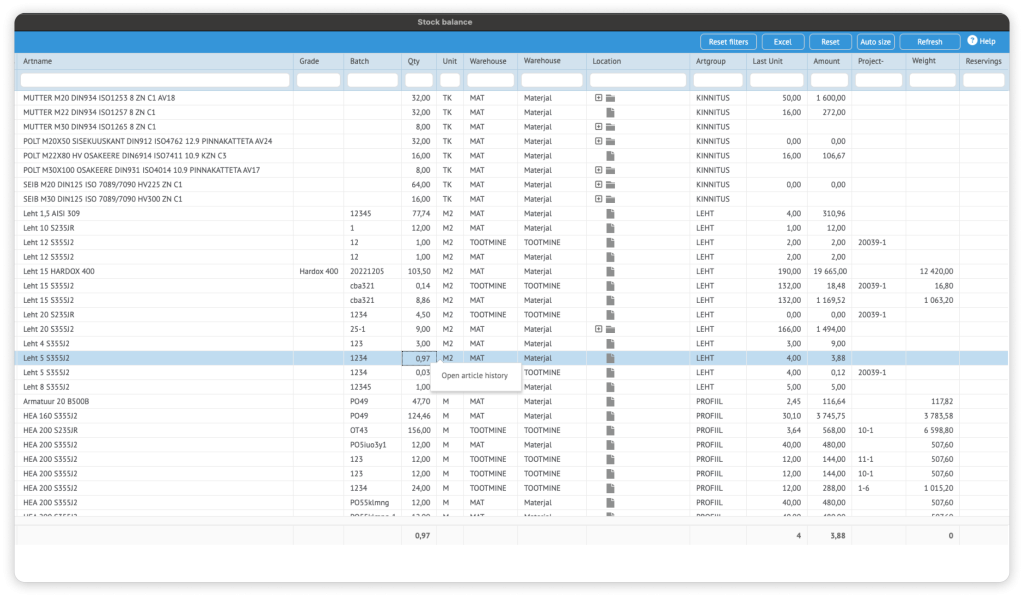

- Inventory and Traceability

- Subcontractor Management

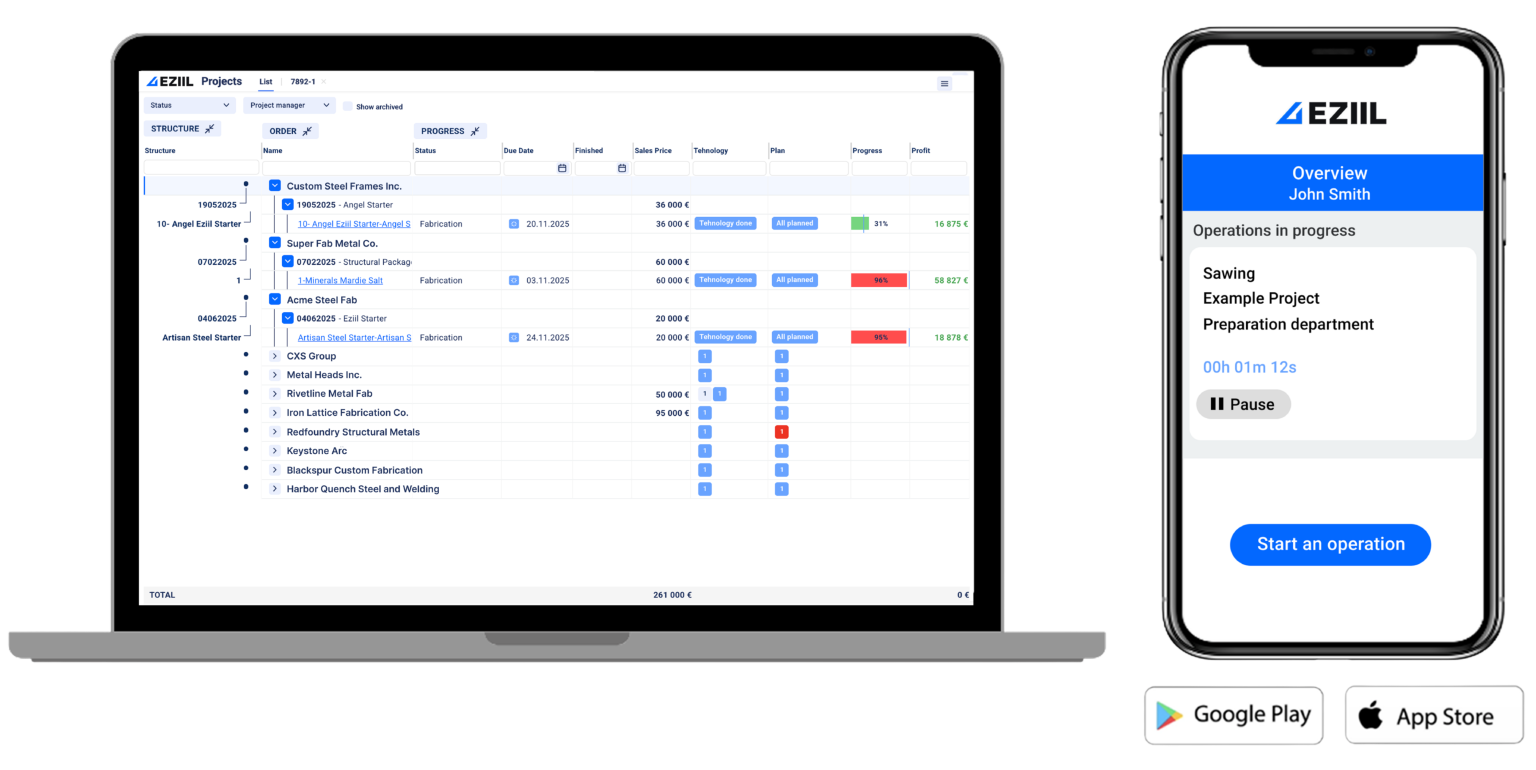

- Shop-floor Control and Mobile Reporting

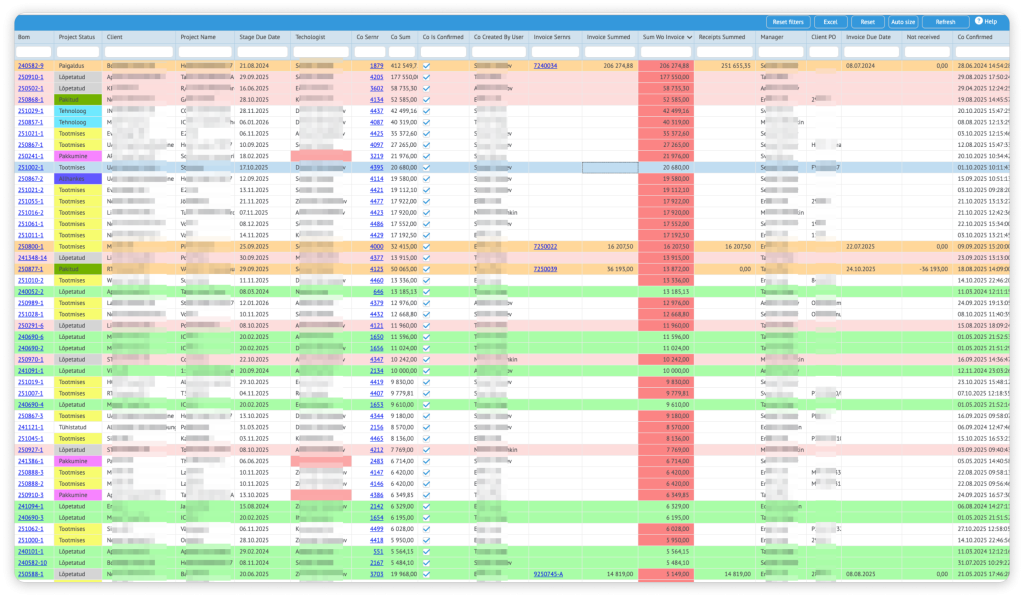

- Invoicing and Accounting Integrations

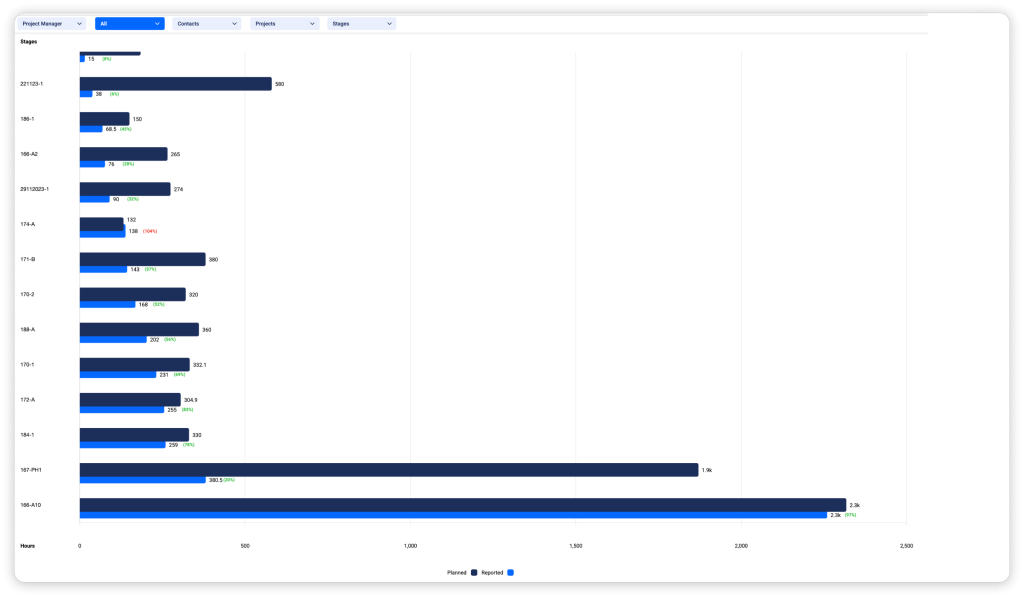

- Advanced Analytics and Profitability

- Automated Notifications Across the Workflow

- Built-for-Fabrication UX and SSO

- Advanced On-Time Delivery (OTD) Tracking

EZIIL Steel Fabrication ERP empowers you to build your own system to unlock throughput and margin

Custom steel shops aren’t cookie cutter. Your ERP shouldn’t be either! EZIIL Steel Fabrication ERP is designed to fit the exact needs and budget of multi-project, make-to-order custom steel fabrication shops. No overwhelming complexity or overhaul changes to your workflow.

You can add modules at your own pace. Only pay for what you actually need and use.

All production info in one place

Advanced BOMs, operations, drawings, POs, stock, labor, deliveries, invoices

Capacity-aware planning

See bottlenecks by department/phase and keep OTD on track

Purchasing that prevents shortages

Demand vs in-stock vs ordered, PR to PO flow, supplier quotes and frames

Inventory and certificate traceability

Receive materials with certificates attached, track movements, issue to jobs, audit-ready

Paperless shop-floor

Labor time capture, drawing/QC on mobile devices, accurate labor costs and real-time progress

Subcontractor control

Create orders with attached drawings/specs, monitor “out” and due-back dates, book receipt to the right operation, capture costs

- Higher profit per project

- Better on-time delivery (OTD) rate

- Shorter PO cycle times

- Cloud-based access

- Intuitive interface

- Built for custom steel fabricators

- Real-time updates

- Google and Microsoft SSO

- Scalable implementation

- Quick and easy adoption

- Monthly subscription, cancel any time

How EZIIL Steel Fabrication ERP works

Connect your shop floor to accounting and your top floor to the shop floor with EZIIL Steel Fabrication ERP!

EZIIL helps you standardize processes, eliminate inefficiencies, and deliver projects profitably while meeting industry standards.

Pick and mix exactly the modules you need to scale throughput, stay audit-ready, and improve profitability.

You can roll EZIIL ERP out all at once or in phases:

import frame agreements → production planning → advanced BOM → machine scheduling → shop floor control → procurement and inventory → dispatching and invoicing → analytics and compliance

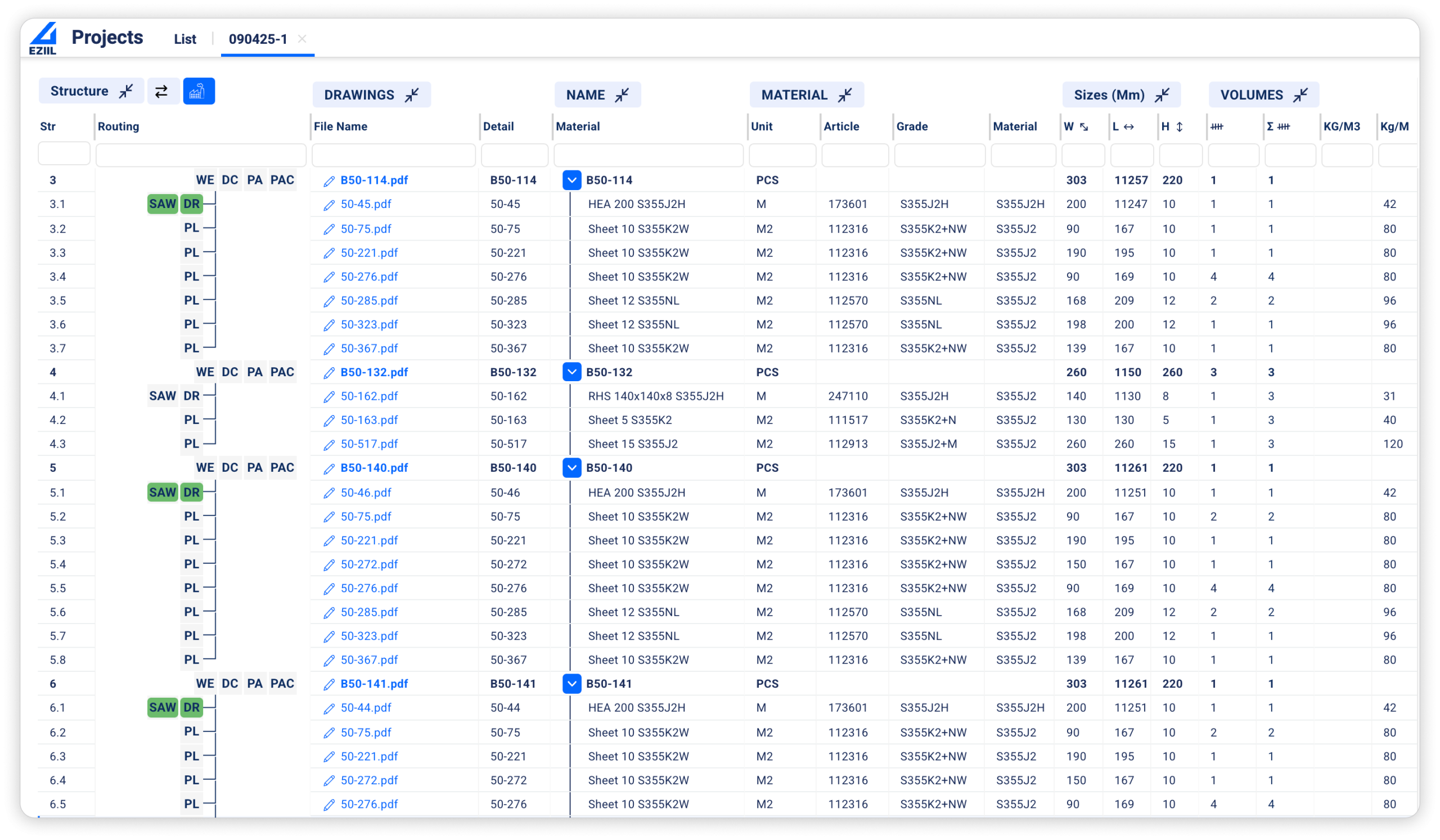

Advanced BOM & Engineering Data

Build the full recipe for each job in one place: BOM, production routing and attach drawings/files to jobs.

Quickly import and create BOM’s directly from IFC/Excel uploads, or copy-paste from any previous project.

Create and reuse production routing templates for similar jobs.

Everyone, from engineering and planning to shop floor and purchasing works from the same current version.

- Multi-level BOM

- Operations and routing

- Drawing/file control

- Custom fields

- Templates and libraries

- Create BOM's from ICF/Excel uploads

- Standardized processes

- Less miscommunications

- Faster handoffs from engineering to production

- Fewer build mistakes

- Quick and easy changes to projects that the whole team sees

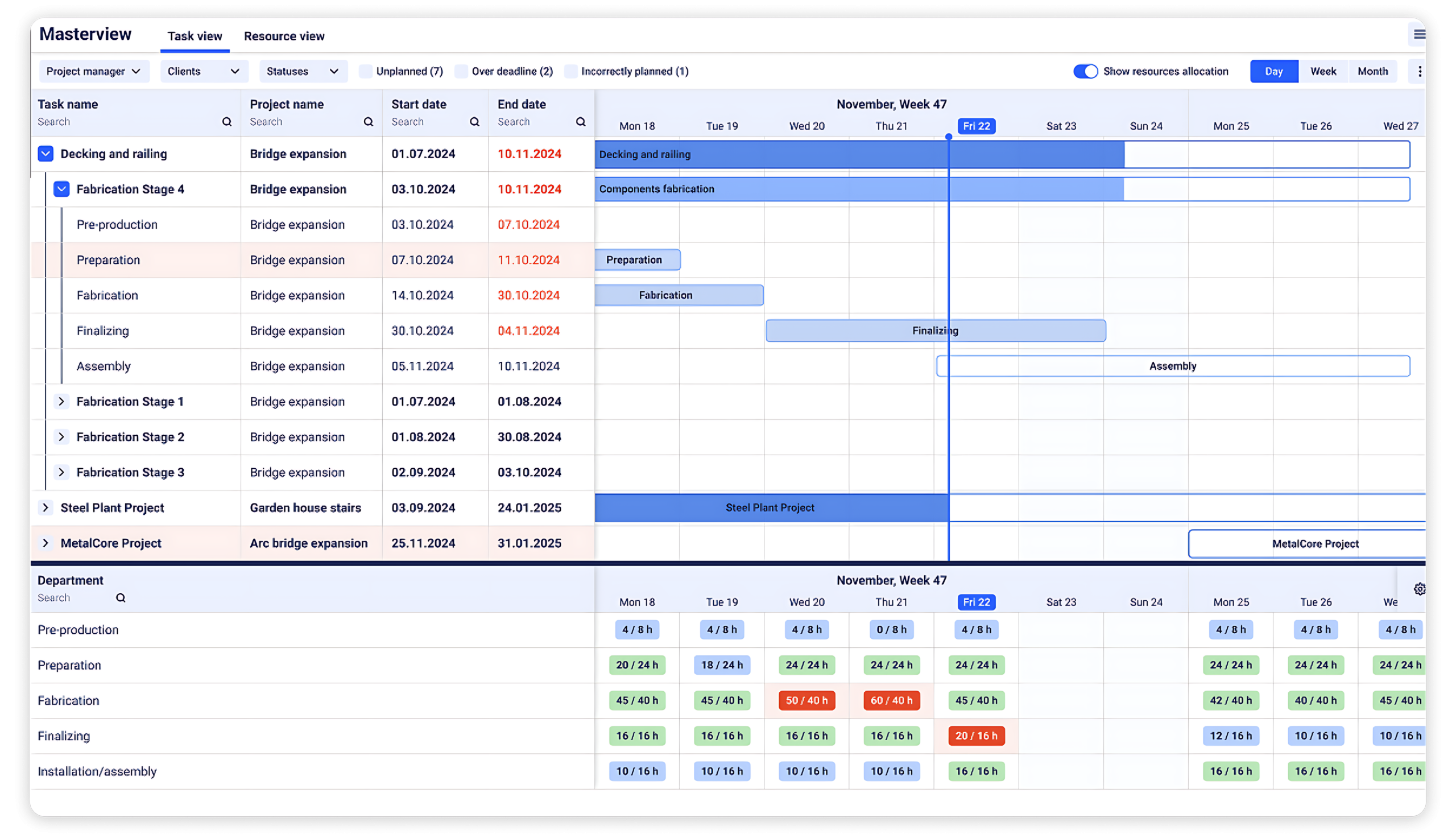

MasterView & Production scheduling

See the whole factory at a glance. MasterView shows each department’s capacity vs the workload and deadlines across all projects (week by week or month by month).

As operators report progress on the shop floor, the information rolls up in real time (percent complete, hours burned vs planned), so planners can spot at-risk deadlines early, rebalance work with a simple “drag and drop” in a visual planning dashboard, and keep finish dates predictable.

- Drag-and-drop scheduler

- Weekly/monthly workload heat map

- Department workload vs capacity

- Auto-schedule suggestions

- Live progress and OTD tracking

- Deadline and at-risk alerts

- Predictable finish dates

- Faster stand-ups and replanning

- More focus on true bottlenecks and deliverability

- Take on new projects with confidence

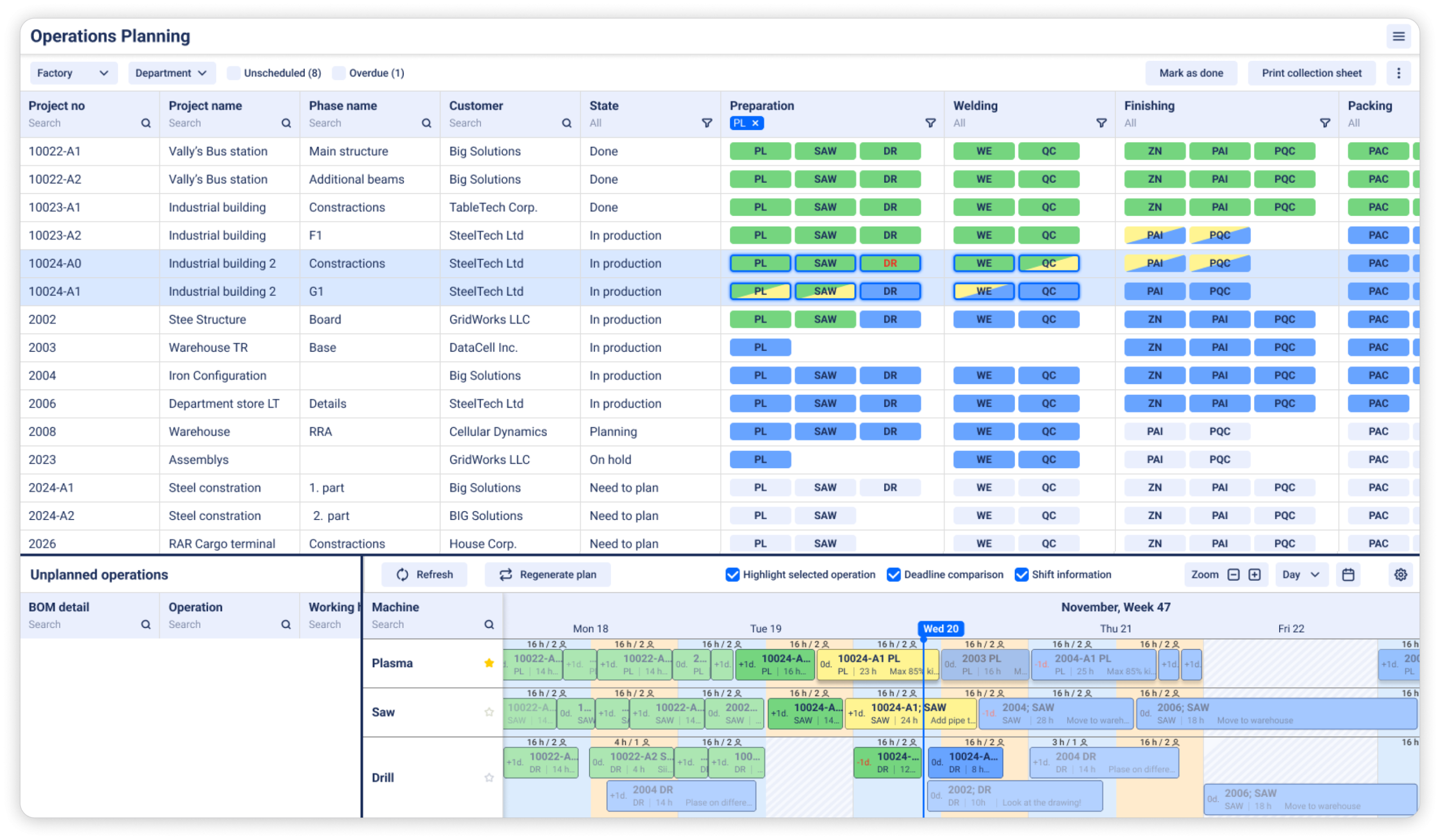

Machine Planning

This is where the big plan meets the exact plan. While MasterView sets the high-level picture (sales commitments, departmental capacity, deadlines), Machine Planning schedules work at the operation level to a specific machine or machine group, or to a specific worker or worker group.

Calendars include shifts, vacations, and sick days, so availability always reflects reality.

Any change you make on your screen updates the shop floor instantly. Operators see the new work orders on mobile/tablet in real time (no walking the floor to re-explain).

- Machine boards (Gantt)

- Operation-level planning

- Changeover optimization

- Define preferred and alternate machines, and capabilities

- Calendars, shifts and downtime

- Split/merge large ops and accept partials into WIP

- Urgent work priority and expedite flags

- Higher machine utilization

- Clear priorities at each station

- Real-time sync to shop floor

- Fewer costly changeovers

- Fast reaction to urgent changes

- Instant communication to the whole team

Deliver on time, every time

Streamline your production with EZIIL Steel Fabrication ERP.

All-in-one production management software for make-to-order steel shops.

Procurement Management

See everything you need to buy in one place (what’s required by each project, what’s already in stock, and what’s on order).

Raise purchase requests (PR) and turn them into purchase orders (PO) in a few clicks, with price comparisons and frame agreements to keep costs predictable.

Reserve shared materials to specific projects (allocate from warehouse stock or from incoming PO lines) so priority jobs are covered when they hit the floor.

- Demand view (needed/in-stock/ordered)

- Generate POs and PRs

- Status and ETA tracking

- Supplier quotes and frame agreements

- PR to PO flow

- Material reservations for projects from stock/PO

- No double-buying

- Fewer stockouts

- Faster PO cycle time

- Seamless collaboration with suppliers

- Buyers, engineers, planners and warehouse work in sync

Inventory & Traceability

Know what you have, where it is, and where it went. When materials arrive, record the receipt and attach the paperwork (certificates/EN 10204 3.1, delivery notes, etc).

Smart alerts will let you know when an expected PO is late or when other inventory thresholds you set are hit.

See stock by location/bin, move items with a clear history, and issue materials to the exact project/operation so usage is traceable for audits.

Production can request a material move/pick to a specific project + operation (what material, how much, from where). The warehouse manager turns that into a move/pick order and executes it.

- Receive materials with certificates attached

- Track inventory movements by project

- Manage outgoing inventory (issue to jobs)

- Stock ledger and locations

- Configurable PO/stock alerts

- Production material requests

- Warehouse move/pick orders

- Full material genealogy for quality and compliance

- Audit-ready records

- Clean handoffs

- Less time hunting for parts

- 8x time and money saved on processes

- Fewer picking mistakes

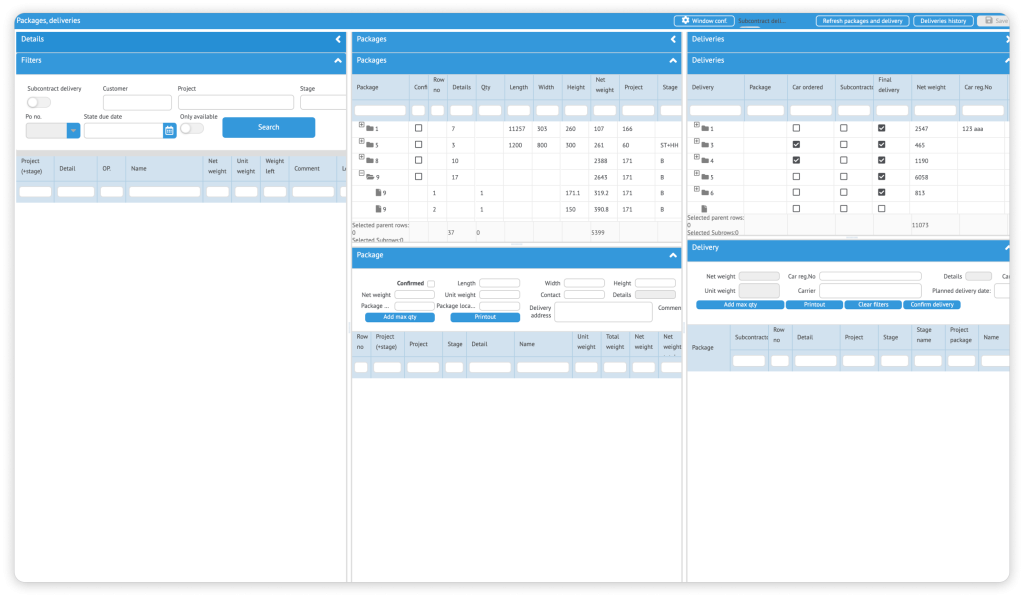

Subcontractor Management

When part of the work happens outside your shop (galvanizing, machining, painting, etc), EZIIL guides you end-to-end: quote request (RFQ) → purchase order (PO) → dispatch of semi-finished parts/sub-assemblies → receipt back → purchase invoice posted to the project’s costs.

Run it simply (quick send/receive) or in detail by creating packages from the items you’re sending, generating a dispatch, and printing packing lists and waybills so nothing gets lost.

- Subcontract order

- Track statuses and ETA

- Certificate attachment

- Partial returns and discrepancies

- Cost capture and purchase invoice

- Audit trail

- Request quotes, compare terms and raise POs

- Reliable lead times

- Accurate job costing

- Fewer lost parts

- Clean back-to-line transitions

- Transparency and clarity in outsourced work

Shop-floor Control & Mobile Reporting

Run the shop floor without paper-printouts and keep materials flowing to the next step.

Operators see what’s next, access the right drawing at the station, start/stop time on the exact task, mark quantity done/left, and add a quick note if something’s off. Supervisors get live status, no walkarounds or phone calls.

In addition to reporting work, operators can also pick and transfer the required materials, semi-finished parts, or components. EZIIL app shows exactly what is needed, where it is, how many to take, and where to deliver. Once transferred, the next operation turns “ready” (green) so the next station can start immediately.

- Mobile time tracking

- Real-time task queue in workers' devices

- Blueprint/QC images on station

- Guided pick and transfer

- Chip-based login (optional)

- Payroll export

- Process-specific views (detail/welding/finishing logic)

- Checklists, notes and photos

- Accurate labor costs

- Live project status and progress

- Fewer interruptions, smoother workflow

- Faster flow between operations

Shipments & Deliveries

Build packages from finished parts/assemblies and any site fixings, then drag those packages onto a dispatch. Print the full document set (packing list, delivery note, CMR for the driver) and track exactly which packages went to which site, when, and with which vehicle.

On site, installers can open the package lists and find what they need fast. Stock and project status update as you dispatch.

- Generate delivery notes for loading team and customers

- Shipment checklist

- Partial deliveries

- Link to invoice

- Plan dispatch

- Package builder for finished parts/assemblies

- Fewer loading mistakes

- Faster installation on site

- Less disputes and back-and-forth with customers

- Accurate stock and project status

Invoicing & Accounting Integrations

Invoice the way your customer agreements work (advance/partial payments or after production) and keep finance in your current accounting system.

EZIIL supports real-world billing models (for example,milestone/phase billing, kg-based, prepayment + partial/final).

Create sales invoices in EZIIL where it fits your flow, or export references and data to accounting for posting and reconciliation. No forced workflow or system changeover.

- Sales-order–based invoicing

- Prepayment and partial invoicing

- Export to accounting

- Export to accounting

- Back-references for control

- Tax and customer mapping (VAT, IDs, payment terms etc)

- Get paid faster

- Reduce double-entry

- Fewer billing disputes

- No accounting system changeover

Advanced Analytics & Profitability

Turn your estimates vs reality into a live scoreboard. At any moment, see how each project, phase, and operation is performing on hours and materials, which ones are at risk, and what’s repeatedly slowing you down.

Track OTD (on-time delivery) trends to stay in promised deadlines and improve future quotes.

- Planned vs actual dashboard

- Profit by project/phase

- OTD trends

- Time-spent analysis

- Repeat issue finder

- Stop cost overruns early

- Quote smarter next time

- Hit deadlines more reliably

- Coach your team with facts

EN 1090-2/EX2–EX3 Compliance

Keep every project audit-ready.

EZIIL links material certificates to work records (who did what, and when), exact assemblies and jobs, so you can prove traceability for EX2/EX3 without chasing paper.

- Certificate storage per PO/project/batch

- Person-operation logs

- Material genealogy

- Audit pack sharing

- Pass audits with confidence

- Qualify for higher-value jobs

- Cut paperwork time

Deliver on time, every time

Streamline your production with EZIIL Steel Fabrication ERP.

All-in-one production management software for make-to-order steel shops.

ROI you can measure

When your shop outgrows EZIIL Starter or a patchwork of spreadsheets, you need a reliable production backbone that fits the exact needs of a steel fabrication shop.

EZIIL Steel Fabrication ERP Software connects purchasing, inventory and traceability, shop-floor, subcontractors, shipments, invoicing, analytics, and EN 1090 evidence so every decision is based on the same live data.

With EZIIL ERP add-on modules, you get:

+ Faster purchasing cycles from consolidated demand and PR to PO flow.

+ Full material traceability with searchable certificates and “where-used” history.

+ Higher on-time delivery (OTD) through capacity-aware scheduling and alerts.

+ Protected margins by spotting overruns early and fixing the root cause.

+ Define BOM fast and send jobs into production immediately.

16%+

Better OTD rate via capacity visibility and alerts

24x ROI

1h invested in EZIIL saves 8h in

procurement and 16h in production

100%

Material traceability with searchable certificate history

FAQ

How is EZIIL Steel Fabrication ERP different from Starter?

EZIIL Steel Fabrication ERP adds Purchasing, Inventory and Traceability, Subcontractors, Shipments, Invoicing, and deeper Analytics on top of Starter’s planning, shop-floor and profitability dashboards.

Can we keep our accounting software?

Yes. Create invoices in EZIIL or export to your accounting system so finance keeps their familiar workflows.

Do workers need new devices?

No. Any shop tablet/PC (and common smartphones) works for time reporting and drawing viewing.

Does EZIIL help with EN 1090?

EZIIL centralizes certificates, materials history and person-task logs to support EX2/EX3 traceability.

How do we handle subcontracting?

Treat subcontractors like operations: send out parts with drawings, track status, receive, and continue the route.

Can Purchasing combine demand across projects?

Yes. See what’s needed vs. in-stock vs. ordered, request quotes, and raise PR/POs fast.

How long does the implementation take?

Varies by scope. Most teams phase the rollout (planning > shop-floor > purchasing/inventory > invoicing/analytics).

What if our data is messy?

We help import and structure BOMs, items, clients, and open projects so you start on solid ground.

Is there a free trial or demo available?

We offer a guided demo to walk you through our platform’s features. Contact our team via the “Book a demo” button to schedule a session and see EZIIL in action.

Can’t find the answer you’re looking for?

Our team of experts is always here to help you.

Get in touch via email.