Job shop management software for small custom steel fabricators

EZIIL Starter offers real-time project dashboards that give you instant insight into your shop’s profitability and schedule.

It’s the all-in-one job shop management software that helps project-based steel fabricators schedule, plan, execute, track, and analyze production in real time.

Without the complexity and hefty price tag of a full ERP.

- Real-Time Production Dashboard

- Create, Manage & Track Projects Visually

- Easy Task & Team Communication

- Single Source of Truth

- Smart Capacity Planning & Scheduling

- Custom Filters & Views

- Task & Resource Allocation

- Mobile Shop-Floor Reporting

- Productivity Tracking

- Production Routing

- Real-Time Profit Tracking

- Workload Estimation

- Planned vs Actual Reporting

- Bottleneck & Workload Insights

- On-Time Delivery (OTD) tracking

All-in-one job shop management software for small steel fab shops

EZIIL Starter is a centralized job shop management software for small and medium (5-50 people) make-to-order steel fabrication shops.

The tool unifies your team with real-time advanced scheduling, profitability insights, at-a-glance progress tracking, mobile reporting and simplified task assignments, eliminating costly mistakes and missed deadlines.

It’s specifically designed to be the first digital job shop management software for teams transitioning from disconnected tools like Excel, Power BI, Microsoft Projects, Google Sheets or pen and paper.

EZIIL’s job shop management software gives you the clarity and control you need to grow your business, without the complexity or high costs of a full-scale ERP.

Connect your top floor to the shop floor today!

- Cloud-based access

- Intuitive interface

- Built for custom steel fabricators

- Real-time updates

- Team alignment

- Google and Microsoft SSO

- Scalable implementation

- Quick and easy adoption

- Monthly subscription, cancel any time

- Higher profit per project

- Better on-time delivery (OTD) rate

How does EZIIL Starter empower small custom steel fabrication teams?

EZIIL Starter is rooted in the best practices and principles of custom steel fabrication project management to support you through all 4 of the key projects’ phases (prepare, plan, report and analyze).

The interactive dashboards connect your project information, departments, profitability, reporting and progress updates in one place.

Manage the full steel fabrication project cycle in one platform

Clarity and alignment from the start of the project.

Rather than wrestling with endless spreadsheets, pen-and-paper notes, and scattered communication, EZIIL’s job shop management software consolidates everything into one intuitive platform, so that your team is aligned and projects on schedule at all times.

1. prepare

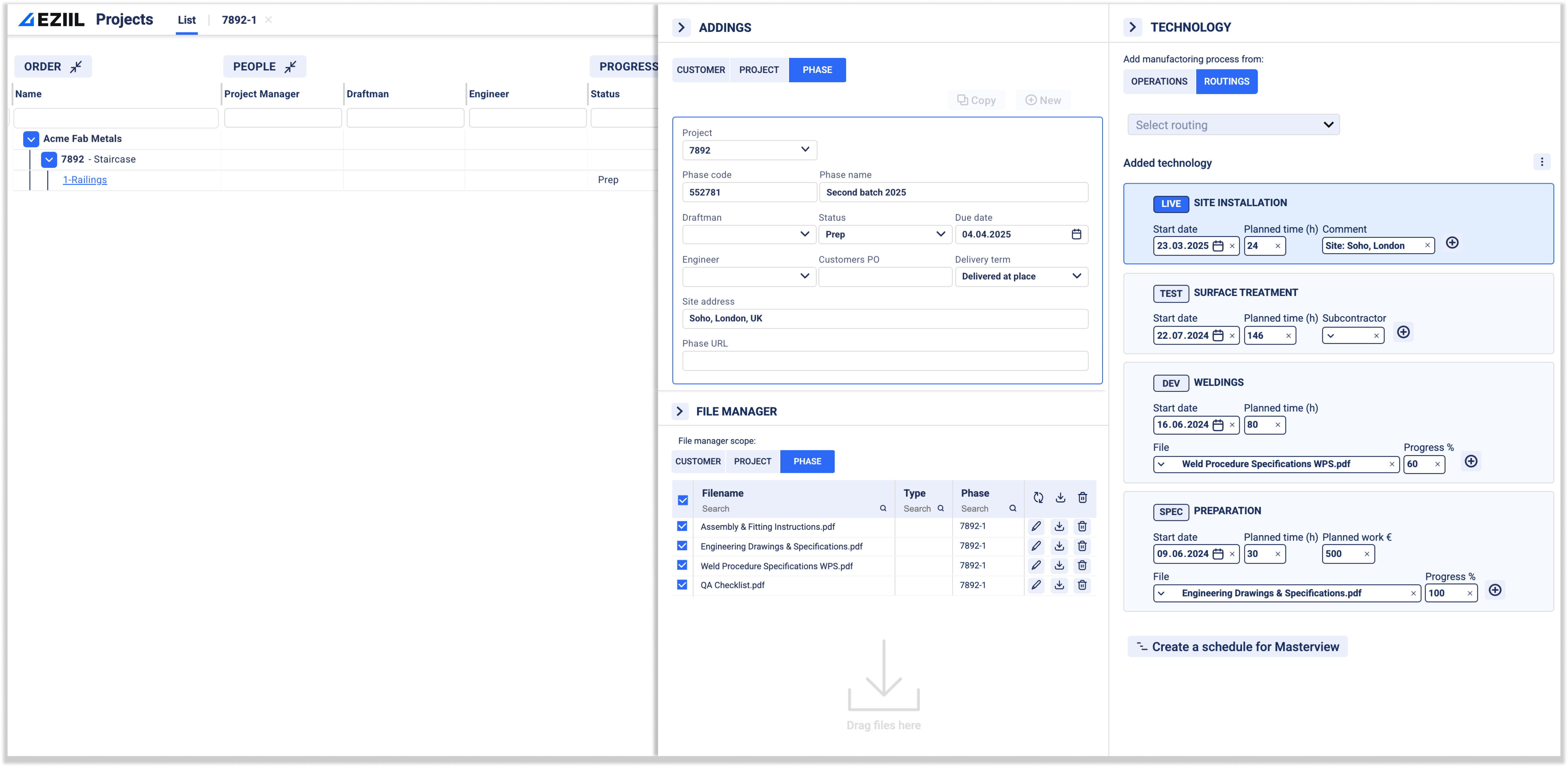

No more scattered Excel files or missing emails.

Organize all project related information such as client data, budget, due dates, project documentation and requirements, workers and phases in one place.

Centralized information hub

Store all project related info, tasks, updates and docs in one place

Custom data fields

Tailor inputs to capture project-specific details

Quick set up for repeat projects

Duplicate similar projects in minutes, no tedious data entry

Production routing

Pre-built fabrication processes’ routing and task templates to save time

File attachments

Drag and drop any files; blueprints, drawings, and docs related to the project directly into EZIIL

Assign roles and permissions

Each team member will have access to the information they need

List of clients

Store all your clients’ data securely in the system and import necessary info to new projects with one click

Organize clients

Group, filter and view projects by client

Arrange projects

Use custom filters to split big projects into sub-projects and phases in one view

2. plan

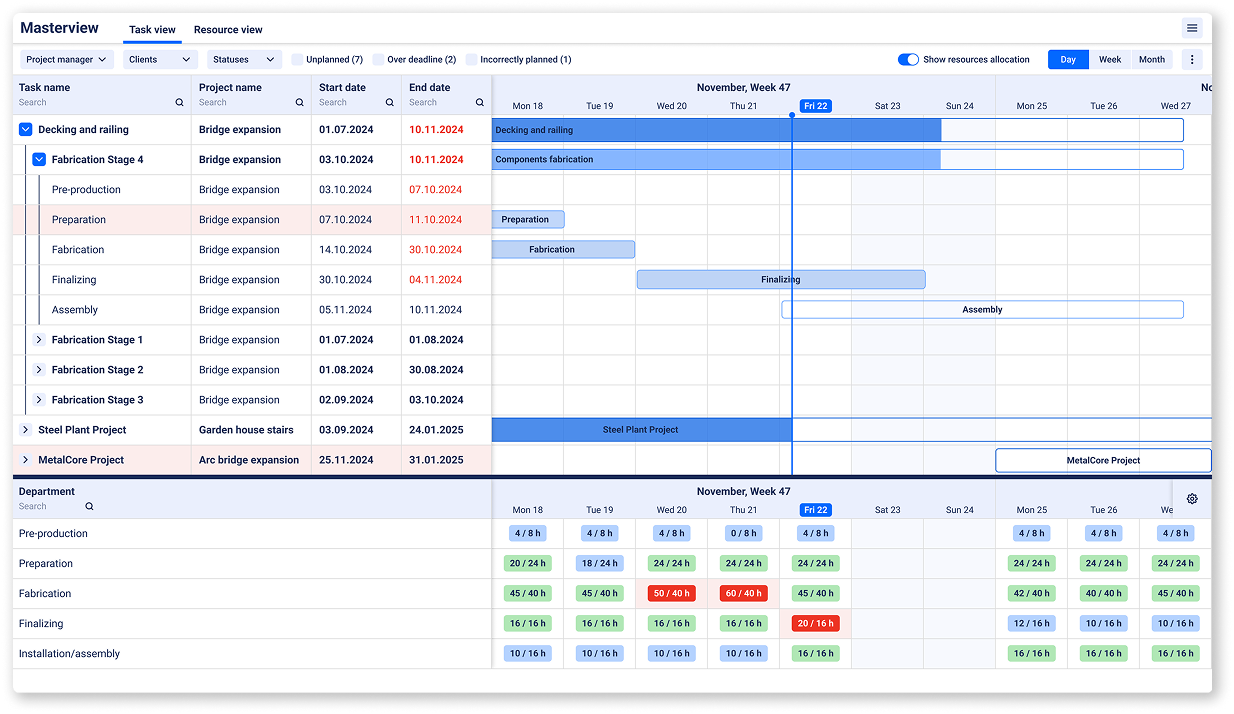

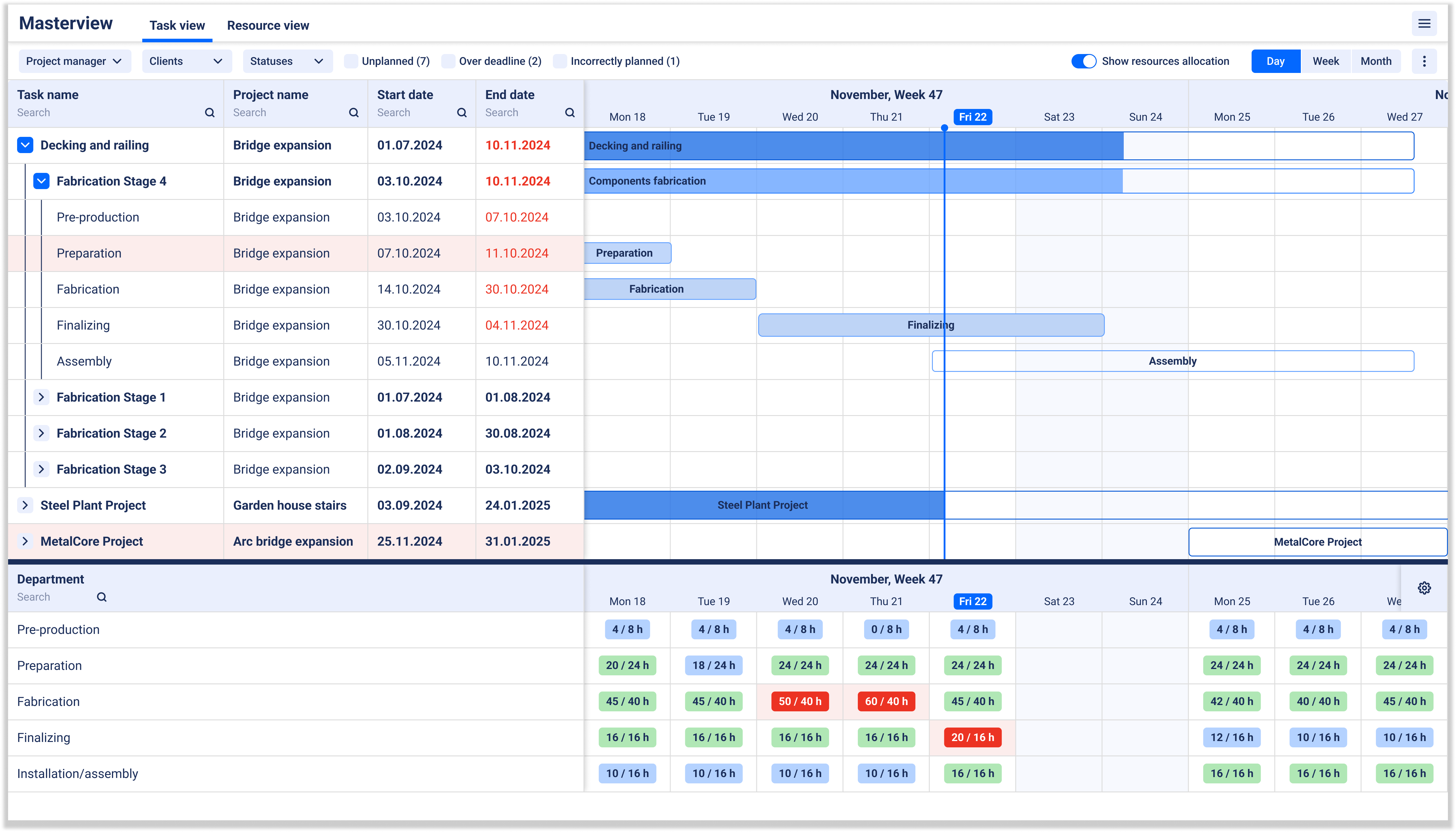

EZIIL Starter helps you create a realistic, conflict-free schedule and immediately shows you if something is off-track or overbooked.

Keep workflows efficient, projects on track and detect bottlenecks early with visual scheduling, real-time resource management, and task assignment to

Schedule project stages

Drag-and-drop scheduler built specifically for steel fabrication timelines, EZIIL highlights any scheduling issues in real time

Resource planning

Accurately plan capacity and prevent bottlenecks and idle time, the planner will show you when you’re over or under capacity

Task assignment

Assign project managers and tasks to departments

Real-time resource overview

Uncover bottlenecks and workload conflicts through a visual map of resources, know exactly how much capacity is booked or free across departments

Team alignment

Keep instructions, and notes tied to specific jobs or tasks

Workflow sequencing

Plan production steps in the correct sequence (cutting->welding->painting)

Real-time progress tracking

Track project progress % in real-time —no more scattered spreadsheets

Auto-schedule projects

Let EZIIL auto-scheduling plan your projects based on your available resources.

Override project progress

Manually adjust reported hours to reflect reality and keep your data accurate, EZIIL will auto-recalculate the timeline and profitability

Deadline alerts & OTD visibility

Never miss key dates with project task timeline-based alerts and on-time delivery tracking

Deliver on time, every time

Streamline your production with EZIIL Starter.

All-in-one job shop management software for small custom steel shops.

3. report

Leverage shop floor control to assign tasks, send work orders, and track real-time progress on the factory floor.

Every worker’s time and progress is captured in real time, so you know exactly who did what and when.

This ensures compliance and traceability with higher Execution Classes (EX2 and above), and creates accountability on the shop floor without any extra paperwork.

Mobile reporting

Shop floor can log hours and update job statuses from their iOS or Android devices

Real-time progress tracking

Understand which tasks are in progress, completed, or delayed at a glance

Accurate labor time logs

Capture real-time labor logs to ensure accurate reporting and improved cost control

Additional work log

Record non-project-related tasks for complete operational oversight

Live task queue

Workers can view up coming jobs instantly, boosting shop floor efficiency

Export work hours to payroll

Edit and confirm logged shop floor work time for accurate payroll calculation

High-class compliance

Fulfill EN 1090 EX2/3 for bigger, traceable contracts

Chip-based access

Fast and simple worker sign-in for seamless job tracking

View blueprints and QC images

Instant access to crucial quality control images and drawings for shop floor workers

4. analyze

Evaluate on-time delivery (OTD) performance, track project profitability in real time and spot trends and inefficiencies.

Know your exact profit margin on each project (and even each phase) in real time. EZIIL calculates expected vs actual profit as the project progresses.

Use these metrics to improve your processes, confidently promise delivery dates to customers and turn what used to be surprise losses into controlled outcomes.

Planned vs reality reports

Spot inefficiencies to optimize workflows and quoting for future projects

Estimate workloads

Learn from past data to take on and schedule future projects efficiently

Project profit overview

Identify which projects are meeting margin and which ones are at risk of you’re losing money in real time

OTD performance metrics

Analyze completion rates, trends in delays by department and team efficiency to improve performance

Trend analysis

Uncover recurring issues, budget leaks and understand exactly what to focus on

Time spent analysis

Get insights on the duration of each operation in production to optimize future processes

Fast and flexible adoption

Large complex ERP and MRP systems can be overwhelming for small steel fabricators and possibly even grind your entire shop to a halt for months. And you probably won’t even use half of the features you’re paying for.

That’s why we’ve made EZIIL Starter super simple, to help you ease into it, step by step, so everyone in your team gets comfortable at your own pace.

You can add on modules and features whenever you feel like you’re ready, without having to pay for the entire system.

With real-time dashboards, you’ll start seeing actionable information (like which project might miss its deadline or how your labor hours are trending) from day one.

That means immediate results!

From the get go, each department is lightly involved, allowing teams to gradually familiarize themselves with the new job shop management software while staying aligned with the entire organization.

The software even provides built-in guidance via tooltips, so your team learns as they use it.

- Beginner friendly, no steep learning curve

- Team training and onboarding support

- Involves every department

- No heavy up-front costs

- See results immediately

- Get up and running in weeks

- Add on modules at your own pace

- We handle setup, data migration, and customization for you

week 1

Initial set up

week 2

Team training

week 3

Go live and optimize

Your first step into real-time job shop management

Small custom steel fabrication shops often manage projects through a patchwork of Excel files, pen-and-paper notes, and other disconnected tools.

This makes it nearly impossible to get real-time status updates, leading to production bottlenecks, missed deadlines and chaotic firefighting.

EZIIL Starter focuses on exactly what a 5-50 person custom steel shop needs day-to-day. Scheduling, tracking, and real-time visibility into jobs.

If you’ve outgrown spreadsheets, whiteboards and pen-and-paper methods, but large ERPs seem like an overkill, EZIIL Starter is the perfect stepping stone.

FAQ

Who is EZIIL Starter designed for?

EZIIL Starter is built for small-to-medium project-based metal fabrication businesses transitioning from spreadsheets, pen-and-paper, and other disconnected tools—helping them streamline project management with minimal disruption.

How is EZIIL Starter different from an ERP/MRP system?

EZIIL Starter focuses on core project management and scheduling needs without the complexity or high cost of a full ERP/MRP. It’s a lightweight Manufacturing Execution System (MES), that’s easy to adopt, and addresses the fundamental pain points metal fabricators face day-to-day.

Does EZIIL integrate with other systems (e.g., accounting software)?

Yes, EZIIL can connect with tools like QuickBooks and other platforms, ensuring you don’t have to abandon the systems you already rely on.

Will I need to replace all my current processes at once?

No. Eziil supports a phased or “layered” approach, so you can adopt new workflows step by step, ensuring a smooth transition for every department.

How does EZIIL handle complex requirements like EN1090 compliance?

EZIIL supports detailed traceability, logging who worked on what and when—crucial for meeting EN1090 standards and other industry requirements.

Can EZIIL grow with my business?

Absolutely. As you scale, you can add on advanced features like BOM management, inventory tracking, and in-depth profitability analysis.

How long does setup and data migration take?

Most shops can get started within a few days. Our team handles the initial setup, data import, and any customization—so you’re up and running faster.

Is there a free trial or demo available?

We offer a guided demo to walk you through our platform’s features. Contact our team to schedule a session and see EZIIL in action.

Can’t find the answer you’re looking for?

Our team of experts is always here to help you.

Get in touch via email.