High mix low volume (HMLV)

What is High mix low volume (HMLV) in steel fabrication?

High mix low volume (HMLV) manufacturing means you produce a wide variety of products, usually in small batches or one-offs.

It’s the opposite of a repetitive production line.

Most custom steel shops are HMLV by default: stairs, rails, frames, platforms, brackets, mezzanines, each with different drawings, tolerances, and routing.

HMLV creates a few predictable challenges:

Scheduling is harder because routing and durations vary

Bottlenecks move around (saw, drill, fit-up, welding, paint, shipping)

“Just start it” thinking creates WIP overload

Quoting can drift if you don’t capture learning job to job

Best practices that work in real high-mix low-volume shops

Standardize what you can: job templates, operation checklists, repeatable sub-assemblies

Plan around constraints: protect the bottleneck with ready work (materials + drawings + approvals)

Short daily coordination (10-15 min): what’s blocked, what must ship, what gets released today

Track plan vs actual by department so quoting improves instead of repeating the same surprises

Reduce handoff loss: clear ownership, clear “next step”, clear due dates

How EZIIL helps High-mix low-volume steel shops

HMLV shops win when information is reliable and visible.

EZIIL’s software is built specifically for custom steel shops and provides:

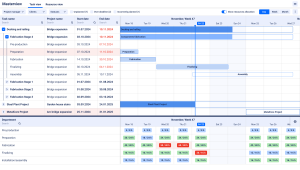

Centralized project tracking keeps engineering, shop floor, and finishing aligned on priorities

Task assignment + statuses make handoffs explicit

Plan vs actual highlights which job types are consistently under-quoted or over-consuming resources

Real-time progress visibility helps supervisors re-balance work before deadlines slip