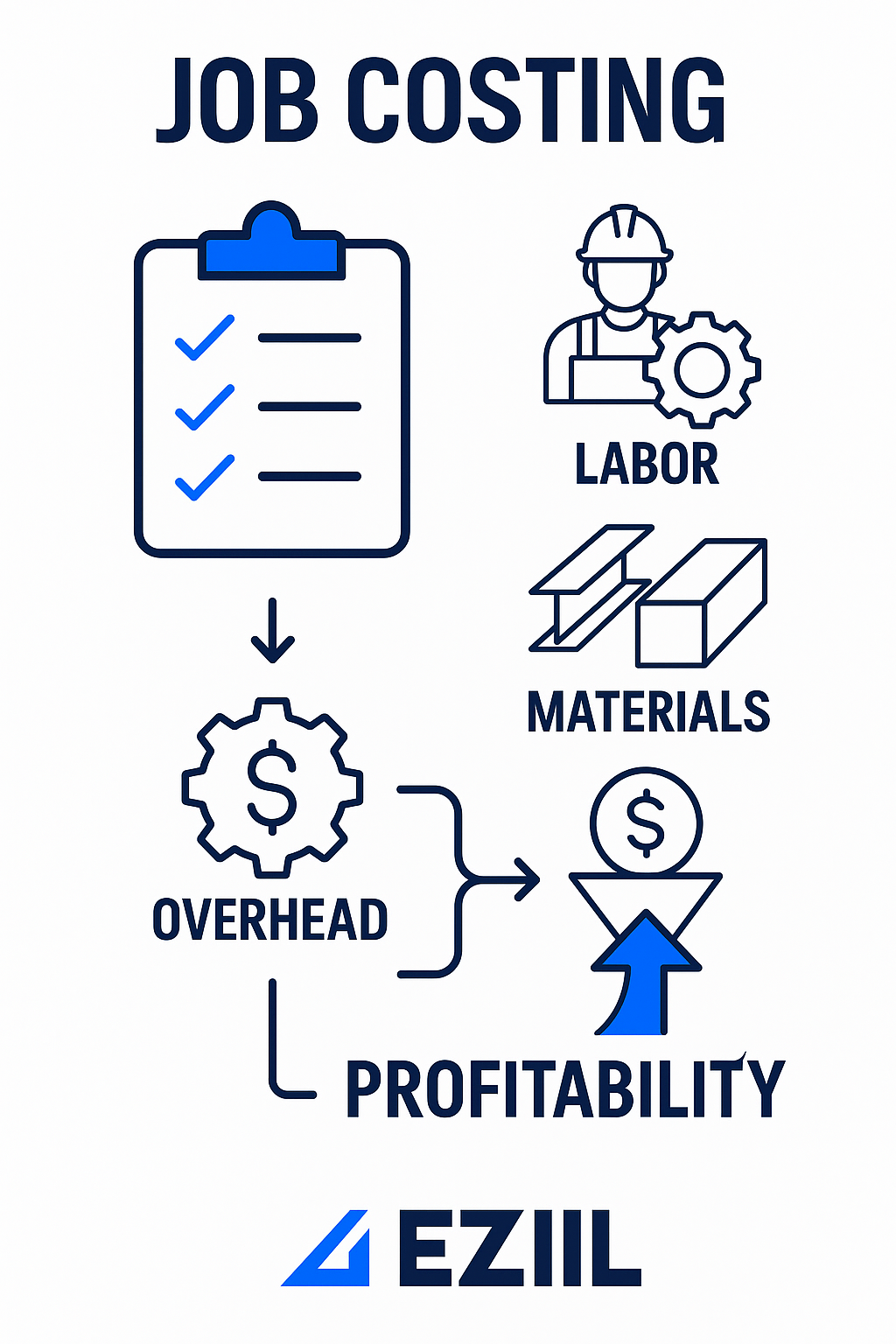

Job Costing

What is Job Costing in steel fabrication?

Job Costing is an accounting method of tracking all costs associated with a specific job or project (including labor, materials, and overhead) in order to determine that job’s profitability.

In a small steel fabrication shop, job costing means collecting the actual expenses for each project: how many labor hours (and at what rate) were spent cutting, welding, painting; how much steel and consumables were used (and their purchase cost); and what share of indirect costs (shop overhead, supervision, equipment depreciation) should be allocated.

By comparing these accumulated costs to the job’s revenue (the price paid by the customer), management can see if they under- or over-estimated and by how much.

Accurate job costing is essential for future quoting, as it feeds right back into estimating standards (for example, “last time we did a similar stair, it took 100 hours, not the 80 we estimated”). It also highlights inefficiencies: if a particular job’s cost was high due to rework or machine downtime, that can be addressed.

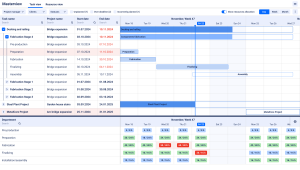

Tools like time tracking on work orders and integrated manufacturing execution systems greatly assist with job costing by job. For example, an executive might review a completed job costing report and find that welding hours were 20% above plan, prompting an investigation and process tweak.

Overall, job costing ensures that each custom project’s financial performance is visible, enabling data-driven improvements and pricing.