Material Requirements Planning (MRP)

What is Material Requirements Planning (MRP)?

Material Requirements Planning (MRP) is a system (often a software module within ERP) that calculates what materials are needed, and when, to fulfill the production schedule.

Essentially, MRP takes your BOMs, looks at current inventory and open orders, and tells you when to buy or make each component so that everything is available just in time for production.

For example, in a steel fab shop, an MRP run might say: based on upcoming projects, you will need 500 feet of 4×4 angle by next month, considering you have 200 feet in stock and 100 feet on order, it will trigger a purchase for the remaining 200 feet to arrive by a specified date.

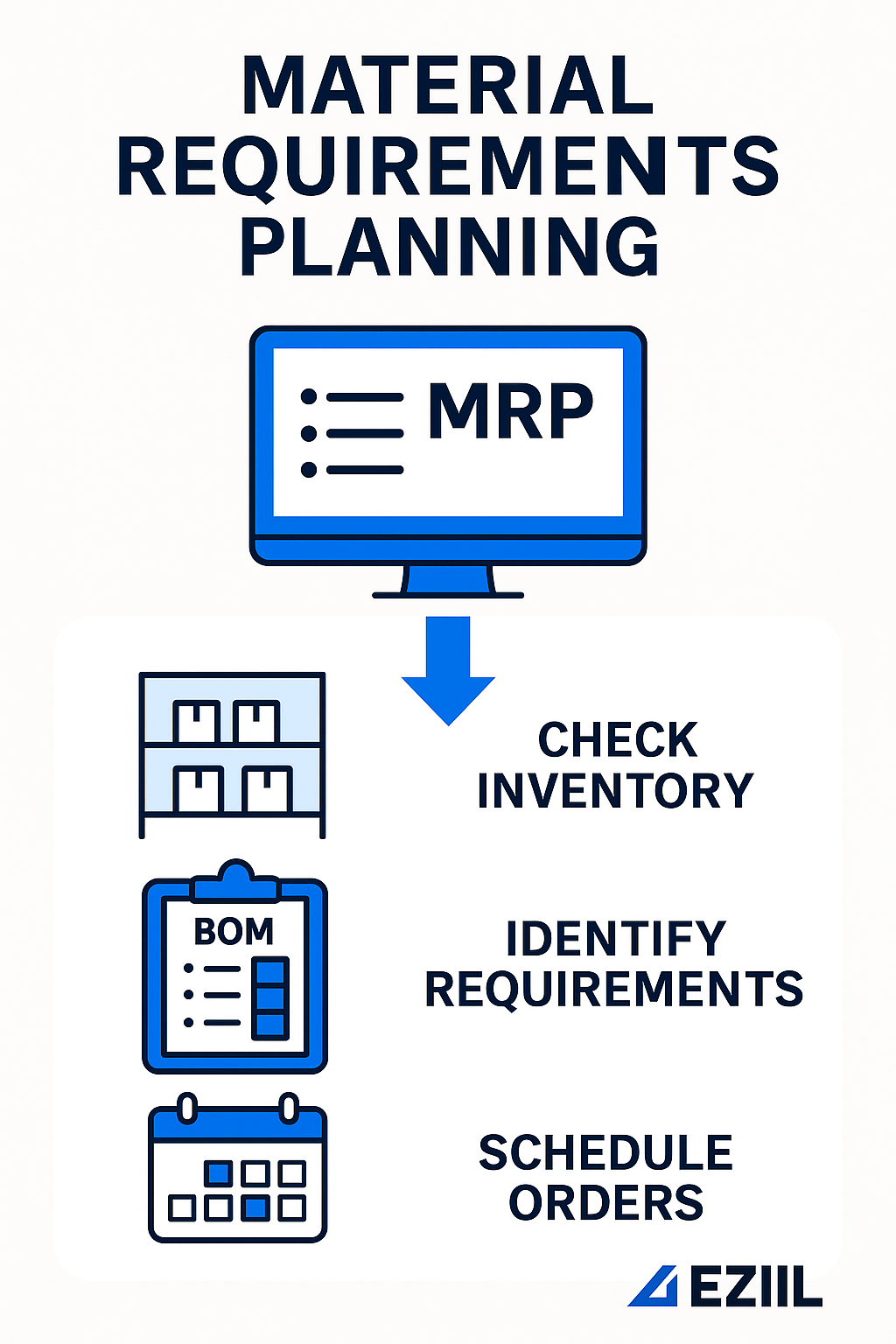

MRP consists of three key steps:

1) checking what you have (inventory on hand)

2) computing what you need and when (netting out inventory and scheduled receipts against BOM requirements and lead times)

3) scheduling purchase or production orders for those needs.

By automating this complex calculation, MRP helps small shops avoid material shortages that could halt production, while also preventing excessive inventory.

It’s particularly useful when juggling multiple active jobs with overlapping material needs and different due dates.