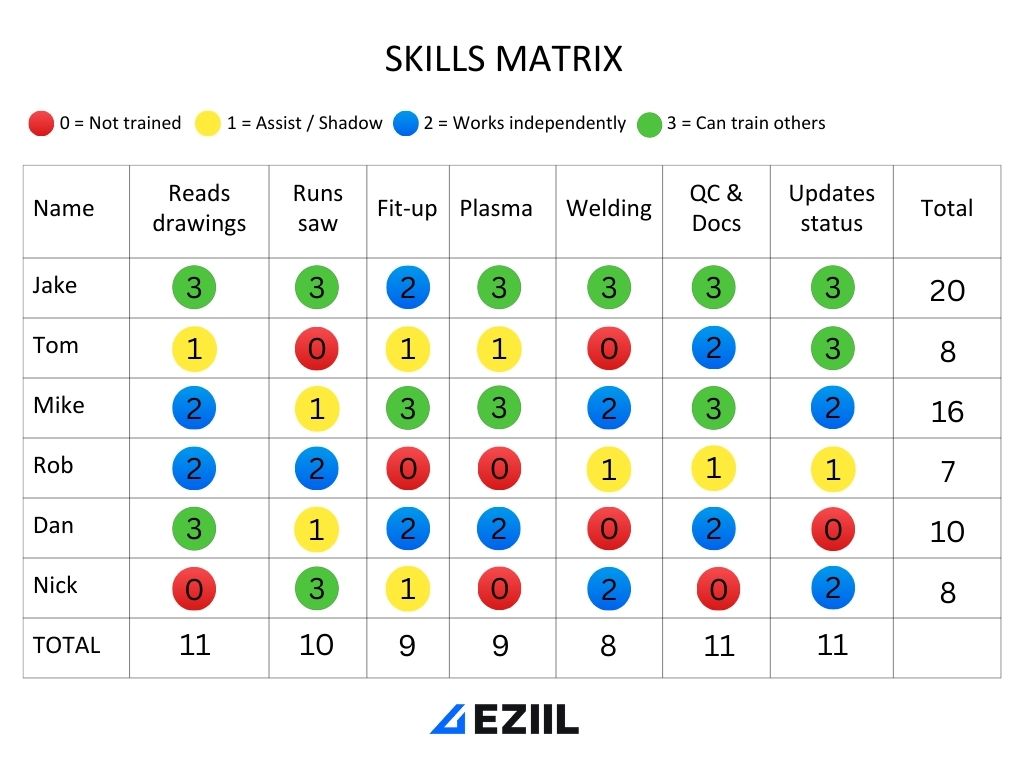

Skills matrix

What is a skills matrix in steel fabrication?

A skills matrix is a simple grid that maps people (rows) against skills or stations (columns), with a clear rating for each person’s competency. It’s used to plan training, cover shifts, and reduce single points of failure.

Why skills matrix matters in steel fabrication?

In high-mix fabrication, headcount is not the same as usable capacity. If only one person can run the press brake, read complex assembly drawings, or weld to a specific procedure, your schedule is fragile.

A skills matrix helps you:

spot coverage gaps before they become late jobs

cross-train around bottlenecks

protect quality and safety (certs, inspections, critical processes)

plan vacations and shift swaps without chaos

Best practices (what works in real steel shops)

Start with the stations that drive ship dates: laser/cut, brake, fit-up, weld bays, paint/powder, assembly, QC/inspection.

Use a simple 4-level scale (example):

0 = not trained

1 = can assist

2 = can run independently

3 = can train others

Define minimum coverage per shift for your key constraints (example: “Brake needs 2 people at level 2+ on day shift”).

Review weekly (10 minutes). Skills matrices rot fast if they are “quarterly projects.”

Tie training to your schedule pain: if welding is always the fire, train for welding coverage, not the least-used station.

Keep it constructive: it’s a planning tool, not a performance weapon.

How EZIIL helps steel shops implement skills matrix

A skills matrix is only useful if it changes daily decisions.

In EZIIL, you can:

assign owners to project phases/tasks and make handoffs explicit

see where work is piling up (for example welding or assembly), then use that signal to target cross-training

store the matrix as a referenced doc for planners/foremen, so staffing decisions stay tied to the live job list

Example in steel fabrication

If your matrix shows only one “level 2+” brake operator, you can proactively:

schedule brake-heavy jobs earlier (while coverage exists)

cross-train a second operator

stop promising tight lead times on brake-heavy work until coverage improves