Throughout their professional careers, mechanical engineers have to work with various file formats. Among these, the NC file often leaves many people scratching their heads and wondering, “What is NC, and how to open an NC file?”

In this comprehensive guide, the world of NC files is thoroughly explored.

The areas mainly covered are the significance of NC files in CNC operations and uncover methods to open and view them, including in Excel.

So, without further activity, let’s embark on this journey to unravel the mysteries surrounding NC files!

Understanding the NC File Type

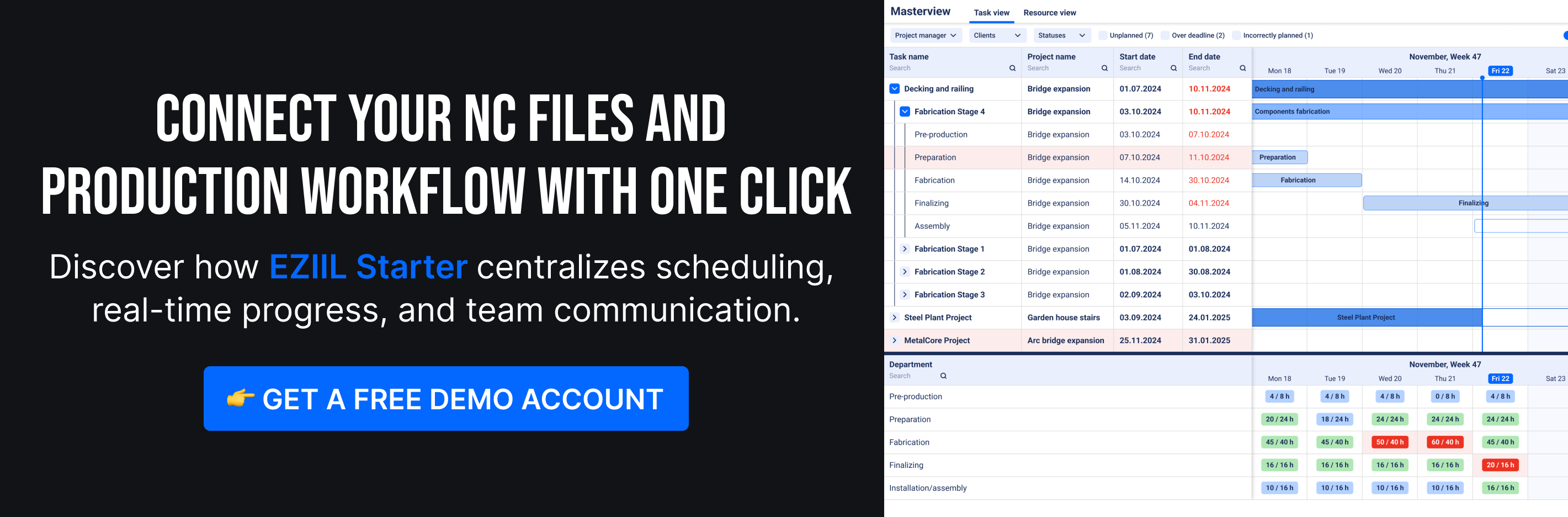

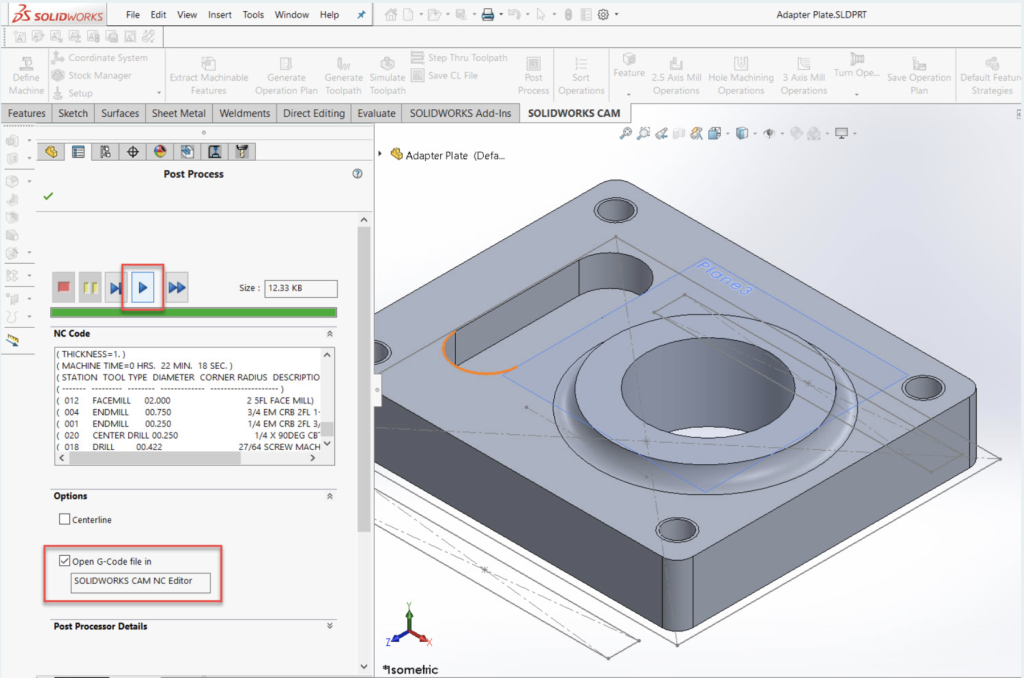

NC file open in CNC Software Mastercam Learning Edition 2023

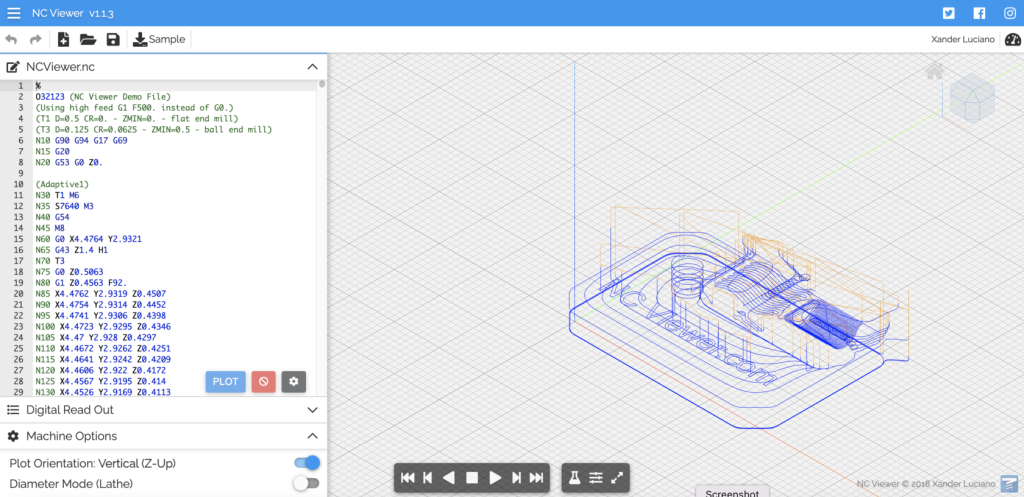

An NC (Numerical Control) file is a text-based file format containing instructions for CNC (Computer Numerical Control) machines. These files store G-code, a programming language that directs the movement and operation of CNC machines, such as milling machines, lathes, and 3D printers. In simpler terms, NC files serve as blueprints for CNC machines to create precise, sophisticated, and accurate designs.

NC files play a crucial role in the world of CNC machining. By converting CAD (Computer-Aided Design) models into a language that CNC machines can understand, NC files act as intermediaries between the digital design and its physical realization. With the help of NC files, engineers and machinists can create complex components with precision and repeatability, making these files indispensable in modern manufacturing processes.

Ways to Open an NC File

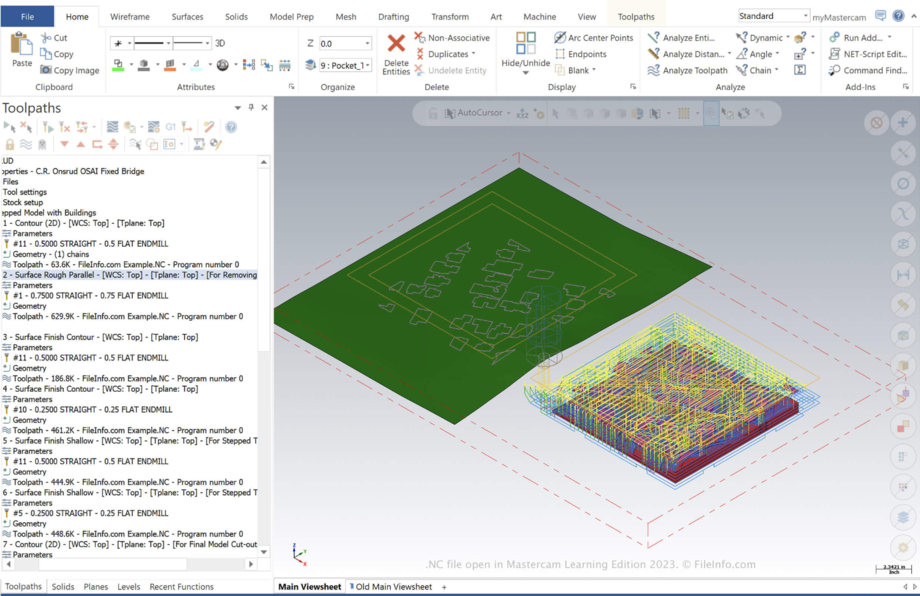

- NC File Viewer: The most straightforward way to open an NC file is by using a dedicated NC file viewer. Software such as CIMCO Edit, G-Wizard Editor, and Predator CNC Editor allows users to view, edit, and even simulate the G-code contained within the NC file. These programs offer a user-friendly interface, making it easy for both experienced engineers and beginners to work with NC files.

- Integrated CAD/CAM Software: Many CAD/CAM software applications, such as Autodesk Fusion 360, Mastercam, and SolidWorks CAM, support importing and exporting NC files as part of their CNC programming features. This method enables users to work with NC files within their preferred design environment, streamlining the design-to-manufacturing process.

- Text Editors: Since NC files are text-based, you can open them using a simple text editor, like Notepad or Notepad++ on Windows, or TextEdit on macOS. While this approach allows you to view and edit the G-code, it does not provide any CNC-specific tools or features, making it less convenient than using specialised software.

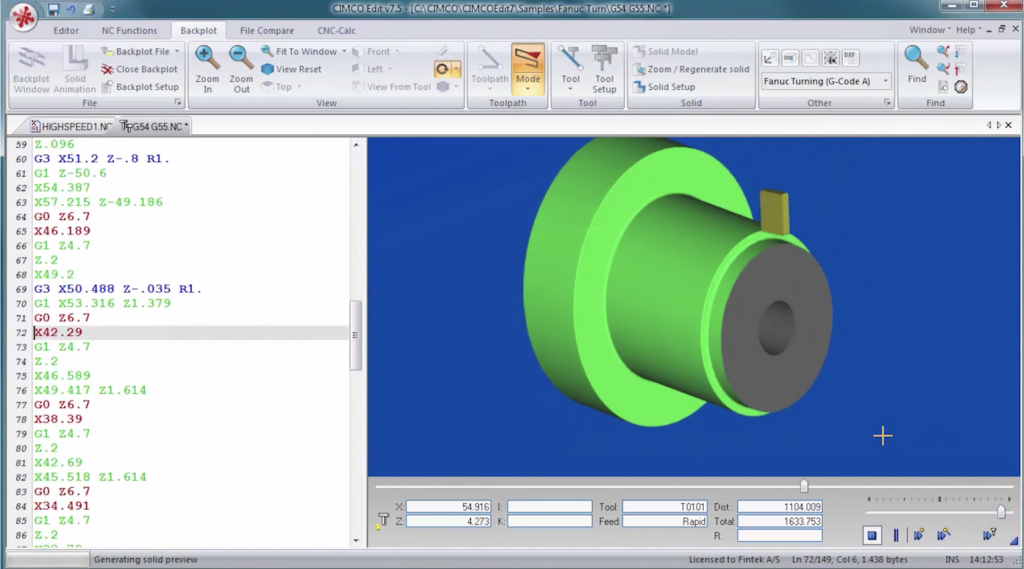

- NC Viewer: Online NC viewers, such as NC Viewer and GCode Viewer, provide a convenient option to view and analyse NC files without the need to install software on a computer. These web-based tools allow users to upload NC files and visualise the G-code, making it easier to understand the CNC machining process. However, these tools may not offer advanced editing or simulation features found in dedicated software.

- How to open .NC Files in Excel: While not the most common method, you can open NC files in Microsoft Excel by importing the text data. Here’s a step-by-step guide on how to do it:

- Launch Excel and open a new worksheet. Go to the ‘Data’ tab and click on ‘From Text/CSV’ in the ‘Get & Transform Data’ group.

- Locate the NC file you want to open, select it, and click ‘Import’.

- In the ‘Text Import Wizard’, choose ‘Delimited’ and click ‘Next’.

- Select the appropriate delimiter for your file (commonly a comma or space) and click ‘Next’.

- Choose the data format for each column and click ‘Finish’.

- Click ‘Load’ to import the data into your Excel worksheet.

While opening NC files in Excel allows for data manipulation and analysis, it is not the most suitable method for editing or simulating G-code. Using specialised NC file viewer software or integrated CAD/CAM software is recommended for those tasks.

NC & NC1 File Formats:

Similarities and Differences

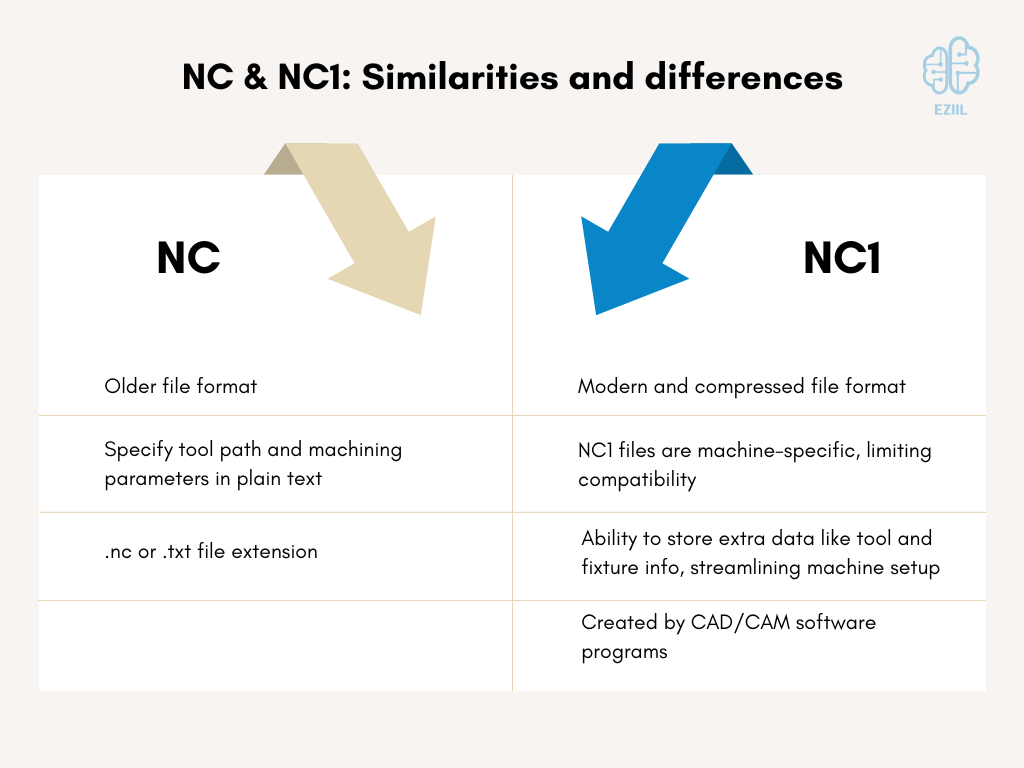

NC (Numerical Control) and NC1 are both file formats used in CNC (Computer Numerical Control) machining, but they are not the same format.

NC is an older file format used to store CNC machine tool programs. NC files contain a series of instructions that specify the tool path and machining parameters in a plain text format. NC files typically have a .nc or .txt file extension and can be edited using a text editor.

On the other hand, NC1 is a more modern and compressed file format used to store CNC machine tool programs. NC1 files contain the same type of information as NC files but are typically smaller in size since they are compressed. NC1 files are machine-specific and may not be compatible with other CNC machines. One advantage of the NC1 format is that it can store additional information, such as tool and fixture data, which can be used to automate the setup of the machine. NC1 files are usually created by CAD/CAM software programs and can be loaded into the CNC machine’s control software for execution.

In summary, the main difference between NC and NC1 file formats is that NC is an older plain text format, while NC1 is a more modern and compressed file format that can store additional information and is typically created by CAD/CAM software programs.

Decoding the NC Extension: Common Variants and

Their Differences

While the term ‘NC file’ generally refers to a Numerical Control file containing G-code, there are several variations of the NC extension that might be encountered in work. Some of the common ones include:

- .nc: This is the standard NC file extension, which is used for storing G-code instructions for CNC machines.

- .tap: TAP files, sometimes called “RS-274 files,” are another variation of NC files that contain G-code. These are commonly used in the machining of printed circuit boards (PCBs).

- .gcode: GCODE files are another type of NC file format containing G-code instructions. These are often used for 3D printing applications.

- .cnc: CNC files are yet another variation of NC files containing G-code. The primary difference lies in the file extension, but the content and functionality remain the same.

These different NC file extensions serve similar purposes, with the primary difference being the naming convention used by various CNC machines, software applications, or industries. Regardless of the specific extension, the methods described earlier for opening and viewing NC files should work across these variations.

Maximising the Potential of NC Files: Tips and Best Practices

For product design and mechanical engineering professionals it is crucial to master NC files for optimising workflow and enhancing the efficiency of CNC operations. To get the most out of the NC files, here are some tips and best practices to keep in mind:

- Maintain a Structured File Organisation: When working with multiple NC files, ensure that you maintain a well-structured file organisation system. Organise your files into clearly labelled folders based on project, material, machine type, or any other relevant categorization. This will save you time and effort when searching for specific files and make it easier to manage your CNC projects.

- Keep G-code Clean and Commented: When editing or creating NC files, make sure to keep G-code clean and well-organised. Use comments to provide context for specific sections or operations, making it easier to understand and modify the code later on. A well-documented G-code file is invaluable for troubleshooting and maintaining CNC programs.

- Validate and Optimise G-code: Before running an NC file on a CNC machine, always validate the G-code using a simulator to ensure that the program runs as expected and to identify any potential errors or issues. Many NC file viewer software and integrated CAD/CAM applications offer built-in G-code simulation tools. Leveraging a G-code viewer, these instructions contained in NC files can be visualized and analyzed, enhancing understanding of machine operations and optimizing performance. Additionally, consider optimising G-code to reduce machining time, tool wear, and material waste.

- Stay Updated on CNC Technologies and Software: The world of CNC machining is constantly evolving, with new technologies and software applications emerging regularly. Always keep updated on the latest advancements in CNC programming, simulation tools, and machine capabilities. This enables us to leverage the most recent features and improvements to optimise NC files and CNC operations.

- Develop and Implement Standard Operating Procedures (SOPs): Creating and implementing standard operating procedures for working with NC files ensures consistency, quality, and safety in CNC projects. These SOPs should cover all aspects of NC file handling, such as file naming conventions, file organisation, editing practices, and validation processes. Having well-defined SOPs in place will help prevent errors and improve overall efficiency.

- Collaborate and Share Knowledge: Collaborating with team members or other professionals in the field will help gain new insights and learn about best practices for working with NC files. Sharing knowledge and experiences can lead to innovative solutions and improved workflows, benefiting everyone involved.

By following these tips and best practices, it is easy to maximize the potential of NC files in product design and mechanical engineering projects. Developing a solid foundation in working with NC files will not only enhance CNC operations but also contribute to a professional growth in the competitive world of manufacturing and engineering.

Conclusion

An NC viewer’s role transcends the basic function of simply opening NC files. It becomes an integral part of your CNC workflow. With an NC viewer, you can dive deep into the content of your NC files, enhancing understanding and fostering precision in your work. Whether it’s for simulation, editing, or basic viewing, an NC viewer is a tool you can count on.

Every CNC programmer, whether a seasoned engineer or a novice, will find the user-friendly interface of an NC viewer incredibly beneficial. The NC viewer allows them to unravel the G-code, leading to more precise and efficient machining.

Navigating the vast seas of CNC programming becomes simpler with an NC viewer as your compass, making it the unsung hero in the world of NC files.

By taking full advantage of an NC viewer’s capabilities, you bring an extra layer of accuracy and efficiency to your CNC machining process, truly making the NC viewer an invaluable tool in the CNC industry.

NC files are essential components in the world of CNC machining, acting as the bridge between digital designs and their physical realization. Familiarising yourself with the different ways to open and view NC files, such as using specialized NC file viewer software, integrated CAD/CAM software, or even Microsoft Excel, will empower you to work effectively with these files in product design and mechanical engineering endeavors.

Now that you have a thorough understanding of what NC files are, how they relate to CNC operations, and how to open and view them, you can confidently tackle any project involving these versatile and critical file types. Remember that the key to success lies in using the right tools for the job and understanding the unique features and capabilities of each method.