Sheet metal bending is a crucial process in manufacturing, construction, and automotive industries. It involves the deformation of sheet metal to create 3D shapes and designs, making it a popular choice for constructing products with complex geometries. The versatility and durability of sheet metal make it an ideal material for various applications, offering a range of benefits for businesses across different industries.

Bending steel plate is commonly used in the construction industry, while bending curved sheet metal is prevalent in manufacturing applications. The process of sheet metal bending requires specific tools and techniques, such as brakes, rollers, and presses, providing manufacturers with the flexibility to create a range of products efficiently.

Sheet Metal Bending Techniques

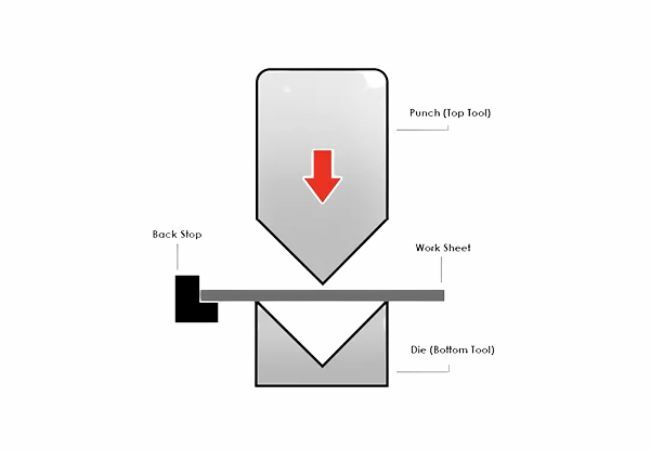

Image credit: https://kdmfab.com

Knowing how to bend sheet metal is an essential skill for workers involved in sheet metal bending projects. There are different methods that can be used depending on the desired outcome:

Folding sheet metal is a popular technique for bending, involving a brake or bending machine to create straight bends.

This method uses a clamping bar and bending leaf to produce sharp and clean bends.

It is efficient and commonly used for long, straight bends.

Equipment required for folding sheet metal includes a brake, clamps, and vices.

Image credit: https://kdmfab.com

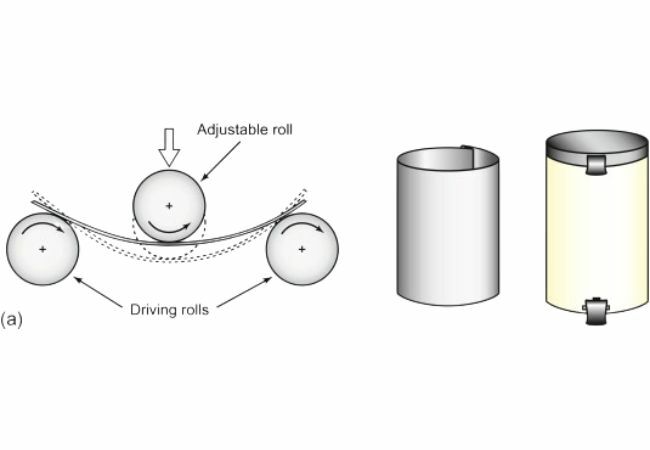

Curved sheet metal is another method of sheet metal bending used to create more complex curved shapes and designs.

It involves creating a curved bend in a sheet metal using a press brake or rollers.

The press brake uses a die and punch to create the desired bend, while the rollers use a series of rollers to shape the metal. Curved sheet metal is used in the manufacturing of products such as ventilation ducts and cylinders.

The equipment needed for curved sheet metal includes a press brakes (for example, a hydraulic press) or rollers, clamps, and vices.

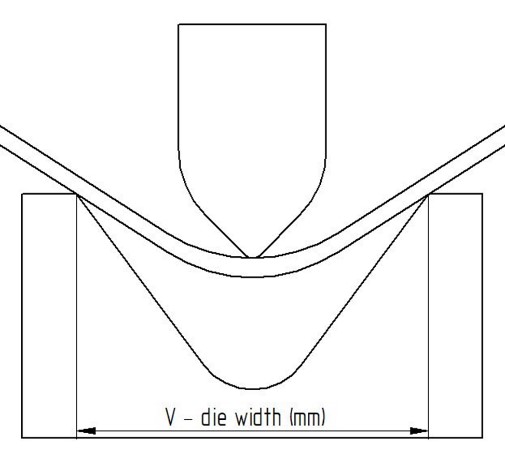

Air bending is a widely-used sheet metal bending technique that involves positioning the sheet metal on a die, with the bend line aligned over the die’s apex.

A punch is then applied to the material, forcing it to bend around the die’s profile.

One of the key advantages of air bending is its versatility, as it allows for multiple bend angles to be achieved using a single die and punch setup.

Additionally, air bending exerts less force on the material compared to other bending techniques, reducing the risk of damaging the sheet metal.

Bending sheet metal without a brake is a technique used when a brake is not available. Basic principles include marking the metal, securing it with clamps or vices, and applying even pressure using improvised tools like pliers or a hammer.

The bend angle can be adjusted by gradually increasing pressure.

Care should be taken to ensure the metal is held securely to prevent slipping or damage.

Read more about sheet metals: Sheet Metal Fabrication 101

Book a 60-minute demo to see

how eziil mrp solution works for you

Calculating Bending Allowance and

Bend Deduction

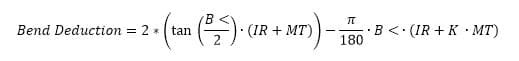

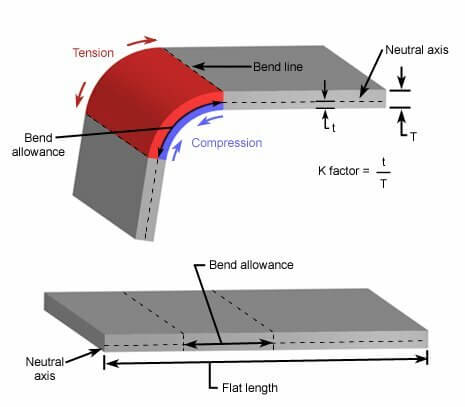

Calculating bending allowance and bend deduction is a critical step in the sheet metal bending process, as it ensures that the final product matches the intended design accurately.

The bending allowance is the amount of material added to the flat pattern of the sheet metal to account for the material’s elongation and bending angle, while the bend deduction is the amount of material subtracted from the flat pattern to account for the material’s compression during bending.

To calculate the bending allowance and bend deduction accurately, manufacturers use specific formulas based on the sheet metals material properties, thickness, and bend angle.

Manufacturers can also use sheet metal bending calculators and bend deduction calculators to simplify the calculation process. These tools allow manufacturers to input the required data, such as material properties, sheet thickness, bend angle, and sheet metal bend radius, and the calculator will provide the bending allowance and bend deduction values.

See the bend deduction formula below (image credits: https://www.metafab.com).

Determining the 90 Degree Bend Calculation

and Radius Bend Sheet Metal

The importance of the 90 degree bend calculation lies in its ability to provide manufacturers with a quick and efficient way to calculate the necessary bend allowance for sheet metal bending.

This calculation is essential in ensuring that the bend angle is correct and the overall product design is accurate.

To calculate the 90 degree bend, manufacturers use a formula that takes into account the thickness of the sheet metal and the radius of the bend. The formula is as follows:

Bend Allowance = Angle * (π / 180) * (Radius + K-factor * Thickness)

*Where K is a constant that is dependent on the material type being used.

To use this formula, manufacturers first determine the material thickness and the inside radius of the bend. They then choose the appropriate K value for the material being used and plug these values into the formula.

The resulting number is the bend allowance, which is the amount of material that needs to be added to the flat pattern of the sheet metal to compensate for the bend.

Image credit: https://www.adhmt.com

Tips for Successful Sheet Metal Bending

When it comes to sheet metal bending, there are a variety of factors that come into play to ensure a successful outcome.

This process involves the use of specialized tools and techniques to transform flat sheets of metal into complex shapes, and requires a high level of precision to achieve the desired result. Common mistakes and challenges in sheet metal bending can lead to distortion and warping of the material, which can compromise the quality of the final product.

However, with careful planning and attention to detail, it is possible to avoid these issues and achieve precise, accurate bends.

One of the most important factors to consider when designing sheet metal parts for bending is sheet thickness. In order to ensure uniform bending and avoid distortion, it is important to use sheets with a consistent thickness. This will help to ensure that the material behaves predictably during the bending process, and will make it easier to achieve the desired different shapes.

Another important consideration when it comes to sheet metal bending is the minimum bend sheet metal radius. In order to prevent fracturing or warping of the metal, it is essential to maintain a minimum bend radius that is at least equal to the thickness of the sheet. This can be accomplished by selecting the right tools and techniques for the job, and by carefully planning the layout of bends to ensure that they are all in the same plane.

These factors can all have an impact on the quality of the final product, and it is important to select the right tools and techniques to achieve the desired outcome.

By paying attention to these factors and taking a careful, measured approach to sheet metal bending, it is possible to achieve precise, accurate bends with minimal distortion or warping of the material.

Ensuring Quality and Safety in

Sheet Metal Bending

Quality and safety are crucial factors to consider in sheet metal bending projects to avoid costly mistakes and delays in production.

Compliance with sheet metal bending standards and regulations is essential to protect metal workers and ensure that the final product meets quality standards.

Failure to comply with these standards and regulations can result in fines, legal action, and damage to the company’s reputation.

To ensure successful and safe sheet metal bending projects, the company should implement a comprehensive quality and safety management system, including regular training for workers, ongoing equipment maintenance, and inspections of the workspace to ensure compliance with safety and quality standards.

The company should also have a system for tracking and documenting the quality and safety of the finished product, including regular testing to ensure compliance with industry standards and regulations.

The Role of Machine Shops in Sheet Metal Bending

Machine shops are essential in the sheet metal bending process, as they house the necessary machinery and skilled professionals to perform precise and accurate bends. These specialized facilities often use CNC (Computer Numerical Control) machines for consistent and efficient bending operations, ensuring high-quality results.

Machine shops also contribute to the manufacturing process by providing services such as cutting, drilling, and welding, making them a one-stop solution for sheet metal fabrication.

Conclusion

It is essential to prioritize the integration of proper techniques, calculations, and safety measures into our operations. These factors are critical for the success of sheet metal bending projects and for ensuring the safety of our employees and customers.

We have highlighted the importance of calculating bending allowance and bend deduction accurately and provided an overview of the different techniques for sheet metal bending, including folding, curved, and bending without a brake.

We have also discussed tips for achieving precise bends, selecting the right tools and materials, and managing different factors that can affect quality and safety.

Overall, companies need to prioritize sheet metal bending techniques, calculations, and safety measures in their operations to ensure successful and safe sheet metal bending projects.

We encourage companies to review their current processes and make necessary changes to ensure compliance with sheet metal bending standards and regulations.

By doing so, we can prevent potential risks and ensure successful sheet metal bending projects that meet high-quality standards.