Metal strength is a critical factor that determines the ability of a metal to withstand external forces and retain its structural integrity. In materials science, strength is defined as the ability of a material to resist deformation or failure under applied loads or stresses.

Metals are widely used in various industries due to their exceptional strength and durability, making them ideal for applications where structural stability and reliability are crucial.

The strength of a metal is determined by several factors, including its composition, microstructure, and processing methods. Metals with a high degree of crystallinity and closely-packed atoms tend to be stronger, as they can resist deformation more effectively.

Furthermore, the addition of alloying elements and the application of heat treatments can also enhance the strength of metals.

Not on EZIIL BOM yet?

Here’s a free online Steel Weight Calculator to help you nail kg/lb fast and avoid over-ordering, surprise freight-class up-charges, and “gotta-grab-a-bigger-forklift” emergencies.

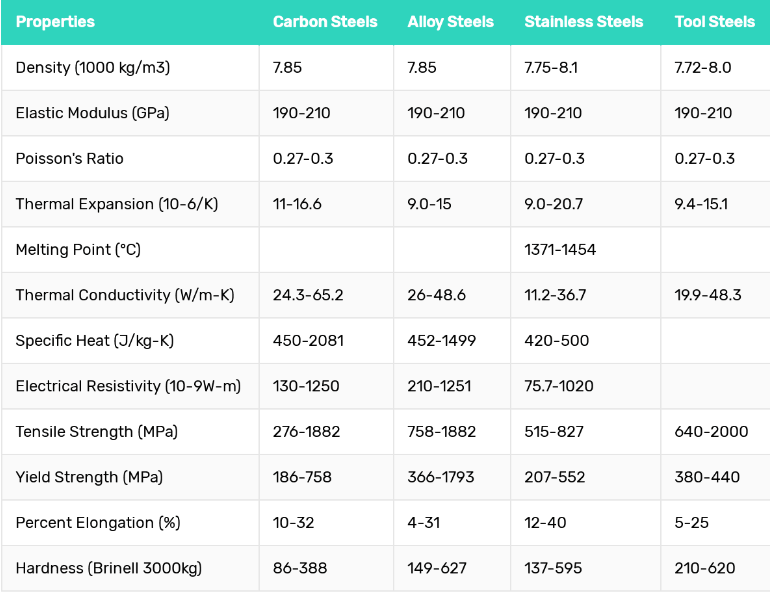

Metals Strength Chart

Most metal strength charts list a minimum and maximum load that the metal can withstand before breaking. When looking at metal strength charts, it’s important to understand that the strength of a metal is relative to other metals and to the properties of the material itself.

A metal’s strength can also be affected by factors like temperature and humidity. Published metal strength charts are commonly used to compare the strength of different metals.

These charts usually vary in their measurements of strength, but they all seek to measure the metal’s ultimate tensile strength.

Strength Charts of Different Metals

We can refer to the strength charts of different metals, based on our needs. Mainly we encounter the strength charts of steel, aluminum, copper, brass, iron, magnesium, zinc, and nickel. But the most important of all of these is the strength charts made for the different alloys of steel. So, the steel strength charts will be discussed in the following paragraphs in detail.

Conversion Chart

Understanding metal strength becomes much easier when you have a reliable reference tool like a ‘conversion chart’. Such a conversion chart gives you an organized view of each metal’s endurance – its minimum and maximum load capacity – as compared to others. But we don’t stop there.

Alongside the conversion chart, we consider other critical elements like temperature and humidity and their effects on the metal’s strength. As you navigate the complexities of metal strength using our guide, you’ll find that it serves as a comprehensive conversion chart.

Whether you’re evaluating the ultimate tensile strength or comparing different metals, our conversion chart-inspired guide simplifies complex metrics for informed decision-making in your manufacturing processes.

Steel Strength Chart

When purchasing steel, an engineer or manufacturer may require a steel strength chart to be created to ensure the perfect material for whatever project is underway. The steel strength chart, also known as a steel plate chart, can be created by inputting the weight and width of the desired steel plate. The engineer then calculates how much force is required to deform the desired steel plate under a certain amount of pressure. This information is used to create the appropriate steel grade and specification. A steel strength chart is used by engineers and manufacturers to ensure the safety of steel plates during different types of projects.

One of the most important things an engineer must do when working with steel is to ensure the safety of the material. Throughout the years, there have been several accidents due to steel. By using a steel strength chart, engineers can ensure that the correct steel grade and specifications are used for any project.

The figure below shows a sample steel strength chart, which shows the different properties of various steel grades or types. With the help of this chart, one can easily choose a single type of steel based on the requirements of the ongoing project.

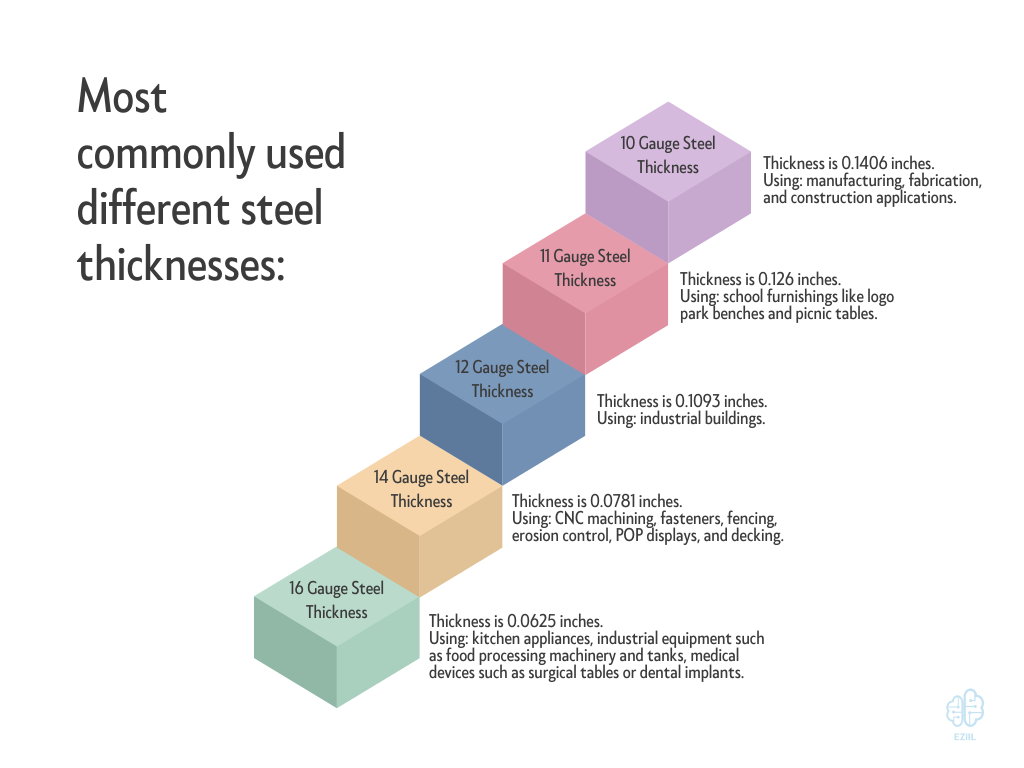

Steel Thickness

When choosing steel for any type of project, the thickness of the steel is important. The thicker the steel, the greater the strength and durability of the finished product. We can find steel with thicknesses ranging from 3/16″ to 18″. But the most commonly used steel thicknesses are 9/64″-1/16″. These thicknesses are also characterized in the form of gauges, i.e., 10 gauge,11 gauge, 12 gauge, 14 gauge, and 16 gauge steel plates.

In the following paragraphs, the most commonly used six different steel thicknesses: 10, 11, 12, 14, and 16 gauge are described in detail.

10 Gauge Steel Thickness

10 gauge steel is generally used for construction purposes, such as building decks and fences. The thickness of 10 gauge steel is 0.1406 inches. 10 gauge mild steel is often used in manufacturing, fabrication, and construction applications due to its strength and versatility.

11 Gauge Steel Thickness

11 gauge steel is a slightly thinner steel than ten gauge steel. The thickness of 11 gauge steel is 0.126 inches. Mostly 11 gauge steel is used for school furnishings like logo park benches and picnic tables in indoor and outdoor areas.

12 Gauge Steel Thickness

12 gauge steel is thinner steel than 11 gauge steel. The thickness of 12 gauge steel is 0.1093 inches. Mostly 12 gauge steel is used in industrial buildings.

14 Gauge Steel Thickness

14 gauge steel is thinner steel than twelve gauge steel. The thickness of 14 gauge steel is 0.0781 inches. Mostly 14 gauge steel is used for CNC machining, fasteners, fencing, erosion control, POP displays, and decking.

16 Gauge Steel Thickness

16 gauge steel is thinner steel than fourteen gauge steel. The thickness of 16 gauge steel is 0.0625 inches. Mostly 16 gauge steel is used to make kitchen appliances like sinks and countertops, industrial equipment such as food processing machinery and tanks, and medical devices such as surgical tables or dental implants. With the increment in the gauges, the thickness decreases, and with the change in thickness strength changes.

Strength of other Metals

As 12 gauge steel has more strength than 16 gauge steel. The same is the case with other metals. Strength is key in metalworking. If a piece of metal is too thin, it can easily bend or break. On the other hand, if a metal is too strong or thick, it can be difficult to work with, and can also be dangerous if not handled correctly.

Metals can be categorized according to their strength and ductility. The three main groups are ferrous metals, non-ferrous metals, and alloys. Ferrous metals are the strongest and have the most resistance to fatigue. Non-ferrous metals, including aluminum, magnesium, and steel, are less strong but more ductile. Alloys are a combination of two of the three main groups and are the strongest and most flexible of all.

It is important to know the strength of metal before beginning a project. This information can be found in tables or charts, or by consulting a metalworking expert. Certain factors, such as the degree of cold working, can affect the strength of a metal. For example, cold working increases the toughness and strength of steel, but can also cause it to lose its temper.

There are a few ways to test the strength of a metal. The most common is the yield test, in which a sample is subjected to a sudden load. The ultimate strength test measures the metal’s resistance to breaking under a repeated load. Both tests are necessary when selecting the right metal for a project.

Sheet Metal

The sheet metal gauge chart proves to be an invaluable tool here, allowing you to quickly and accurately compare different gauges and their corresponding strength attributes.

An appreciation for the inherent diversity in sheet metal varieties can aid you greatly in your manufacturing endeavors. For example, understanding the distinctive strength of stainless sheet metal versus galvanized sheet metal could be the key to unlocking your project’s success. Armed with a sheet metal gauge chart, this becomes a more manageable task.

From exploring the tensile strength of varying types of sheet metal to examining the influence of temperature on sheet metal integrity, we leave no stone unturned. Furthermore, recognizing the malleability and ductility of sheet metal, and how these qualities interact with strength, can be an invaluable asset.

Whether you’re dealing with corrugated sheet metal, decorative sheet metal, or functional sheet metal for industrial applications, our guide, complete with a sheet metal gauge chart, aims to enrich your knowledge and foster a better understanding of sheet metal’s strength. It’s all about empowering you to make well-informed decisions when working with sheet metal in your next project.

Steel Compressive Strength

Introduction

The compressive strength of steel refers to its ability to withstand compression or squeezing forces without breaking or deforming permanently. It is an important property to consider in designing and analyzing steel structures, particularly columns, and beams that are subjected to compressive loads.

Units

The compressive strength of steel is typically expressed in units of megapascals (MPa) or pounds per square inch (psi).

Factors Affecting Steel Compressive Strength

The actual compressive strength of steel depends on several factors, including its chemical composition, manufacturing process, and heat treatment.

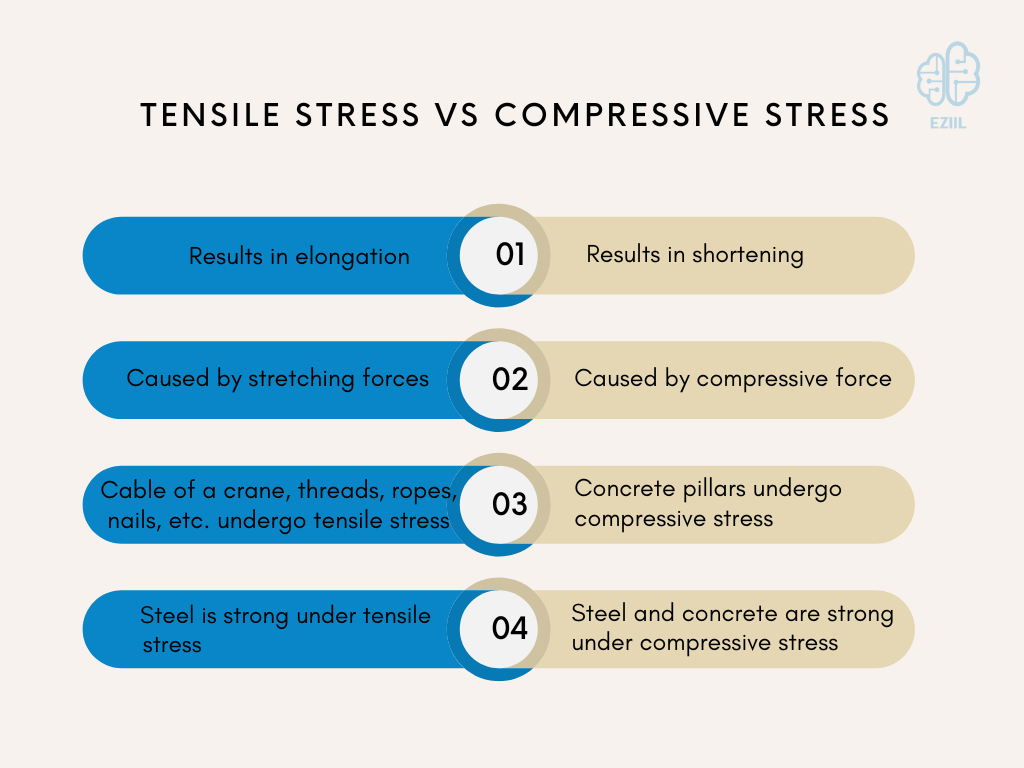

Comparison of Tensile and Compressive Strength of Steel

Generally, the compressive strength of steel is higher than its tensile strength, meaning that it can withstand more force in compression than in tension.

In other words, steel can generally withstand more force when it is being compressed than when it is being stretched. This is due to the nature of the atomic structure of steel, which allows it to resist compressive forces better than tensile forces. Understanding the difference between compressive and tensile strength is important for designing and analyzing steel structures, as it helps engineers determine the maximum load that a structure can safely withstand under different types of stress.

Determination of Steel Compressive Strength

The compressive strength of steel can be determined through various testing methods, such as uniaxial compression testing and hardness testing. These tests involve applying a compressive load to a sample of steel and measuring the stress and strain it undergoes. Understanding the compressive strength of steel is important for ensuring the safety and reliability of steel structures in various applications, such as buildings, bridges, and industrial machinery.

Typical Value of Steel Compressive Strength

Although steel is available in various forms and compositions, a typical value for the compressive strength of steel is about 25,000 psi.

What are Weakest Metals?

In terms of strength, several metals are considered to be weak compared to others. The strength of a metal is usually measured in terms of its tensile strength, which is the maximum stress it can withstand before it fractures under tension. One of the weakest metals in terms of tensile strength is tin. Tin has a tensile strength of about 12 megapascals (MPa), which is much lower than most other metals.

This is because tin has a relatively low number of valence electrons, which makes it more susceptible to deformation and fracture under stress.

Lead is another metal that is considered weak in terms of strength. It has a tensile strength of around 10 MPa, even lower than tin. Like tin, lead has a low number of valence electrons, which makes it more prone to deformation and fracture.

Chart of Metals Strength

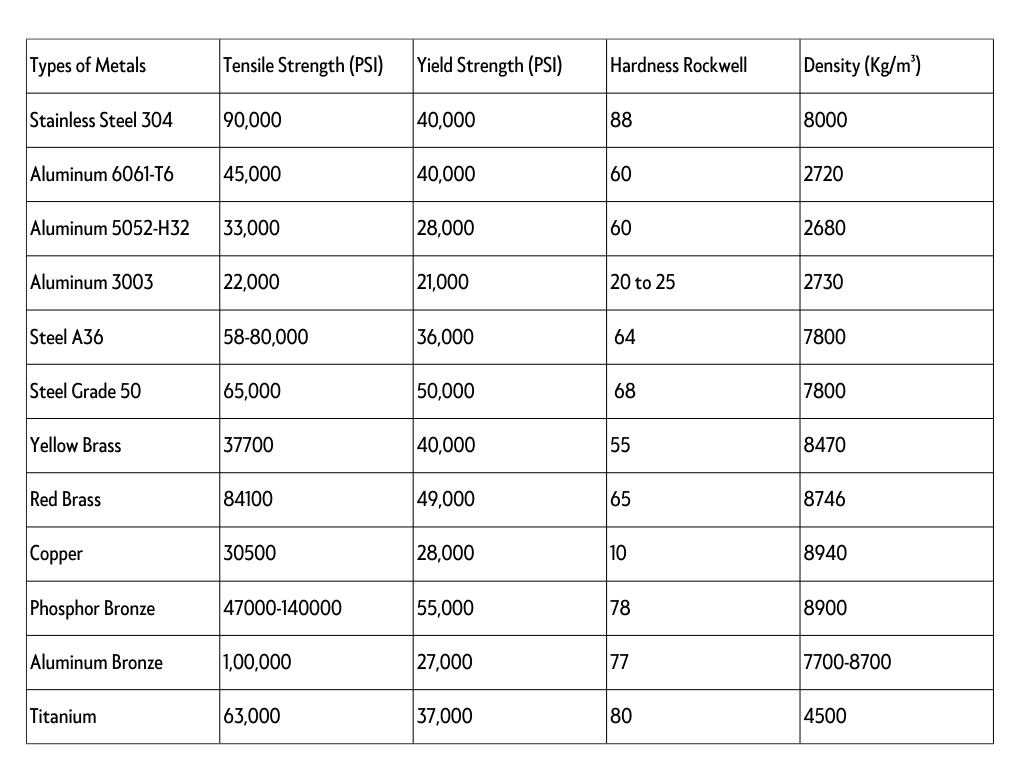

The following chart shows the Tensile and Yield Strength of various metals along with Hardness and Density values.

Metal Tensile Strength

One of the most important factors in determining the strength of a metal is its tensile strength. Tensile strength is the ability of a metal to resist deformation or a tear during the application of a mechanical force. The higher the tensile strength of a metal, the more it will resist breaking or pulling apart.

Steel is a metal that is often used for construction and industrial purposes because of its high tensile strength. In fact, some types of steel have a tensile strength that is nearly three times that of most other metals. Consequently, steel can withstand a great deal of stress before it breaks.

Due to its high tensile strength, steel is often used to build components that are subjected to high levels of stress. For example, steel is commonly used in bridge bracing and scaffolding because it can withstand high levels of tension and stress. In addition, steel is also used in vehicles and ships because it can resist the forces that are exerted on them during operation.

Tensile strength is a vital property in any metal, especially in stainless steel. This trait refers to how much stress a material like stainless steel can endure before it breaks or deforms.

Stainless steel is renowned for its impressive tensile strength, making it an ideal choice in demanding applications. One might wonder, what gives stainless steel its strength? The answer lies in its unique composition, which includes various alloying elements. This composition enhances the tensile strength of stainless steel, allowing it to withstand immense forces.

As a result, stainless steel is commonly used in industries where durability and strength are essential.

So next time you encounter a structure or a product made from stainless steel, you’ll appreciate the impressive tensile strength that stands behind it.

Conclusion

It can be summarized from the above content that the metal’s strength is very important and it becomes more prominent when we talk about the strength of steel. Metal strength is the main factor for maintaining structural integrity and resisting external forces. It is also worth mentioning that the factors such as composition, microstructure, and processing methods influence metal strength.

One of the important things for metal strength is the metal strength charts. These charts are used to compare different metals, while steel strength charts are particularly valuable for engineering and manufacturing works involving steel as a core material. Steel plates are available in various thicknesses ranging from 3/16 in. to 18 in. These steel thicknesses are also referred as gauges i.e. 10 gauge steel plate, 12 gauge steel plate, and so on.

One should also know the difference between compressive and tensile strength in steel, along with methods to determine compressive strength. The weaker metals are tin and lead whose properties are briefly mentioned in the above content.

We can use various charts, graphs, and other data available in the literature to determine the tensile and yield strengths, hardness, and density of various metals including stainless steel, aluminum, steel grades, brass, copper, phosphor bronze, aluminum bronze, and titanium.

Lastly, we should not ignore the significance of tensile strength. It is the metal’s ability to withstand deformation and tearing under mechanical force. Steel is specifically noted for its high tensile strength and its common use in applications subjected to high levels of stress, such as construction, vehicles, and ships.