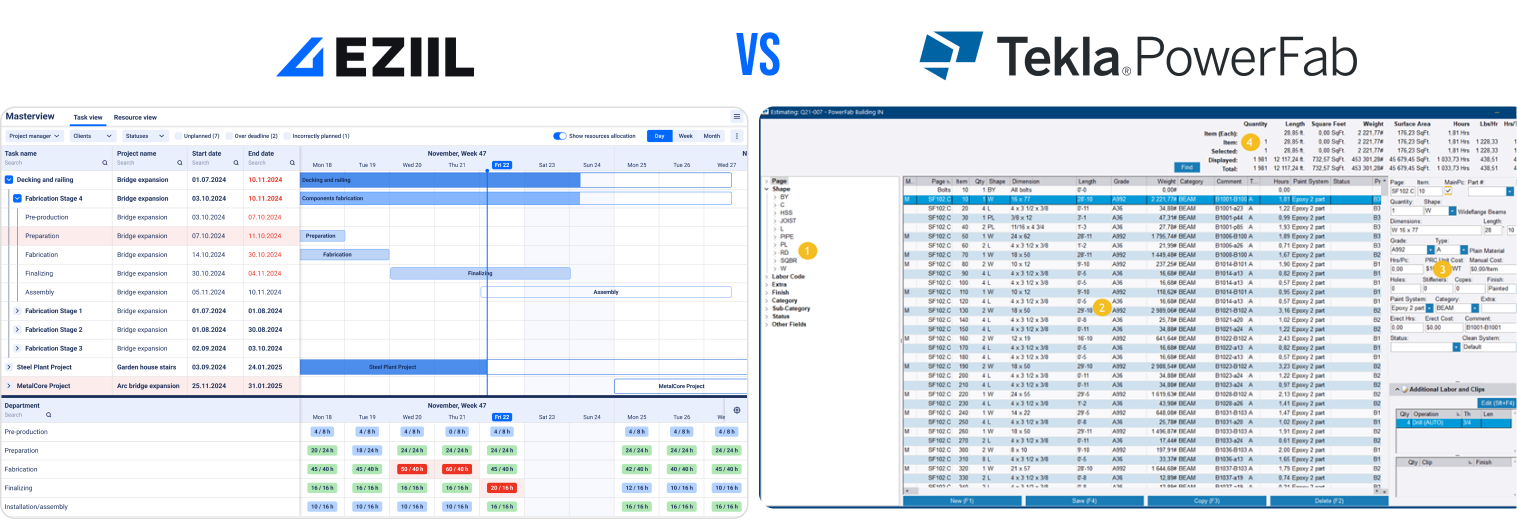

Below you’ll find a side-by-side comparison of Tekla PowerFab vs EZIIL, comparing the factors that matter most to small custom steel fabricators, such as cost, learning curve, scheduling clarity, traceability, and the hidden “gotchas” that can stall production for weeks. Use it as a quick gut check to find the perfect project management and execution tool for your steel fabrication shop.

Tekla PowerFab vs EZIIL at a glance: comparison table

| What matters to a small custom steel fab shop | EZIIL | Tekla PowerFab | Why is it important? |

|---|---|---|---|

| Up-front spend and cash flow | €90/monthly subscription, cancel any time. | Starts at $8000 licence + ongoing sub and training | Lower initial investment and monthly subscription preserve working capital vs tying up money before ROI. |

| Time to first live job | 3-4 weeks guided onboarding. | Several months (data setup, training, possible server/SQL admin). | The faster you can go live with your new software the better. Lost production time is an extra (hidden) cost. |

| Learning curve | Simple and intuitive, doesn’t require a lot of training and shop floor can adapt it in a day. | Multi-module complex screens require formal training. | Usability and ease of onboarding drives wider cross-department adoption. |

| BIM/3D model link | Imports BOMs (CSV/IFC) but doesn’t feature a full 3D visual yet. | Seamless Tekla Structures sync, model-colour progress viewer. | Crucial only if you own Tekla models. |

| Works without in-house detailers | Yes. EZIIL handles PDF/2D drawings and CSV BOMs. | Manual entry heavy if you’re not working with a Tekla model. | Many custom shops rely on external engineers. |

| Scheduling clarity | Drag-and-drop Gantt for scheduling that auto-flags bottlenecks. | Status-code lists, no native visual Gantt. | Instant visual beats code tables for small teams. |

| Cloud vs on-prem | 100% cloud-based. | Core database still Windows/SQL with cloud portal (EPM Go). | Cloud-based software has less IT overhead and auto-applies updates. |

| Built-in estimating | Use any pricing tool; export CSV. | Robust parametric estimator tied to parts DB. | Advantage Tekla if you estimate inside the MIS. |

| Ideal fit | Mixed custom steel fabrication, restricted budget, traceability to EN 1090, quick ROI. | Structural-steel shops already running Tekla CAD, growing to high tonnage. | The right tool for you aligns with your shop DNA. |

Eziil Starter – All-in-One Custom Steel Fabrication Project Management

EZIIL Starter is a cloud-based Manufacturing Execution System (MES) and project management tool built specifically for custom metal fabrication shops. It guides users through all project phases: Prepare, Plan, Report, Analyze. All in one platform.

Key jobs EZIIL addresses include:

- Project planning and scheduling: Visual drag-and-drop Gantt scheduling of fabrication phases (e.g. cutting, welding, painting) with resource capacity planning. EZIIL auto-detects bottlenecks and even offers auto-scheduling based on available resources.

- BOM (add-on module) and document management: Centralizes bills of materials (BOMs) and operations, drawings, files, and custom data for each project. This ensures all departments work off the same, up to date information at all times.

- Real-time shop floor tracking: Provides a live task queue for workers and mobile app reporting so fabricators can log progress and labor hours on the fly. Management can see percent-complete and status of each task or component in real time (no more hunting through paper updates).

- Analysis and cost control: Tracks planned vs actual hours and provides an analysis on project profitability and performance. This helps refine future quotes and identify recurring inefficiencies.

- Communication and team alignment: Assigns tasks to departments or individuals with all instructions attached, so everyone knows what to do. It supports role-based access (for example, project managers vs shop workers). All updates are consolidated, replacing the “endless spreadsheets, pen-and-paper notes, and scattered communication” many small shops struggle with.

Who is EZIIL built for and what are its Use cases?

EZIIL is specifically designed for small-to-mid sized steel fabrication companies that manage custom steel projects (like staircases, small bridges, architectural metalwork, industrial equipment, etc.) and are moving off of disconnected tools like Excel or paper. These are typically shops up to 10-50 employees who find large ERPs overwhelming.

EZIIL is the easiest first step into digital project management for steel fabricators that have outgrown manual methods (Excel, pen and paper, whiteboards, etc.) but can’t afford a complex ERP implementation.

Use case examples:

- A 20-person structural steel fabricator that currently uses Excel for scheduling and folders of drawings on a server. They need real-time insight into fabrication status and a way to coordinate office and shop teams better.

- A job shop making custom sheet metal assemblies who struggles with manual job tracking and frequent rush changes. EZIIL helps them see bottlenecks and manage change orders in one place.

- Any fab shop pursuing EN 1090 certification or similar. EZIIL’s traceability features (logging who did what, storing QC images, etc.) support higher execution class jobs, which is usually beyond the capability of spreadsheets.

EZIIL’s Features and Capabilities

EZIIL provides end-to-end support for steel fabrication project workflows. From quoting, BOM and bill of operations creation, scheduling and capacity planning, shop-floor data capture, through to delivery. It includes quality/compliance tracking (supports EN 1090 EX2/EX3 standards for traceability in structural steel), and reporting dashboards.

EZIIL’s Pricing

EZIIL is offered as a monthly subscription with a base starting at €90 per month (for up to 15 users).

EZIIL’s pricing is modular, so you can start with core planning and add modules as needed, rather than paying for an entire ERP suite upfront. This makes it budget-friendly for small steel fabricators, as there are no large upfront license fees, and you can cancel anytime if needed. (By contrast, something like Tekla PowerFab might start at tens of thousands of euros upfront.)

Implementation and Onboarding

EZIIL Starter is meant to be the first step into digital project management for metal fabrication, and is designed accordingly. It’s lightweight, intuitive, user-friendly and requires minimal learning curve.

EZIIL excels in quick, flexible adoption. No heavy IT effort or long downtime, unlike large ERP/MRP packages that can grind a small shop to a halt for months during implementation. EZIIL can be up and running in weeks.

EZIIL’s Pros

- Metal fabrication focus: Purpose-built for project-based fabricators, so it handles things like multi-phase jobs and custom BOMs intuitively.

- Ease of use: Very intuitive interface and simplified workflow for complex tasks. Users report that even shop-floor workers can adapt quickly with minimal training.

- Comprehensive visibility: Combines planning, scheduling, and tracking. Giving the users real-time production overviews and progress updates at a glance. Eliminates the need to reconcile data from separate tools.

- Collaboration and communication: Keeps all project info (drawings, notes, budgets, schedules) in one place accessible to all departments, which greatly improves team alignment.

- Continuous improvement: Provides “plan vs reality” reports on hours and costs, so you can identify inefficiencies and refine your processes and quoting accuracy over time.

- Scalable and modular: No need to over-invest. You can add modules when ready. Also, it’s cloud-based and scales as you grow, without heavy IT infrastructure.

EZIIL’s Cons

- Requires Internet/cloud: As a cloud solution, if your internet goes down, the system is inaccessible.

- Initial setup and customization: It’s not plug-and-play. EZIIL’s team assists in configuring the system to your shop’s needs (data migration, custom fields). This service ensures a good fit but means an upfront time investment of a few weeks. Some very custom workflows might need further tailoring by EZIIL.

- Limited financials: EZIIL Starter focuses on MES/project management. It doesn’t try to replace full accounting systems. You’d still use QuickBooks or similar for detailed financial accounting (though EZIIL can export needed data). For some, this is a pro (use best-of-breed in each area), but companies seeking an all-in-one ERP including accounting might see this as a gap.

What do EZIIL’s Customers Say

EZIIL’s customer feedback is strongly positive among small fabrication shops. Many see it as “highly beneficial” for digitizing and gaining control of their process. Users especially like that EZIIL guides them step-by-step through implementation and continuously incorporates their feedback and have states that it’s a “solution that evolves with their needs”.

Fabricators often mention how before EZIIL they were “wrestling with endless spreadsheets” and constantly firefighting issues, but after adopting EZIIL, they report improved on-time delivery and less chaos on the shop floor.

One reviewer sums it up: “EZIIL remains a highly beneficial tool for fabrication businesses seeking to optimize their manufacturing process through digitization”.

What Makes EZIIL the Perfect Option for Steel Fabricators

For small fabricators, EZIIL offers a good “just right” solution. It’s more powerful and integrated than spreadsheets or basic MRPs, but far simpler and more affordable than heavyweight fabrication ERPs.

Unlike generic MRPs, it was designed around metal fabrication jobs, so it natively handles things like cut lists, welding stages, and project-based costing. And unlike older industry software, it’s cloud-based and subscription-priced, reducing risk. It’s basically a targeted answer to the exact “jobs to be done” small fabricators have: scheduling the shop, knowing the status of every job in real time, managing BOMs and drawings, coordinating production, and analyzing job profitability. These are precisely the areas where status quo tools fall short and where ERPs either excel but at high cost or are decent but not specialized.

Tekla PowerFab – A Powerful Steel Fabrication Suite

Tekla PowerFab is an all-inclusive steel fabrication management suite aimed at structural steel fabricators of various sizes. PowerFab is scalable from small fabrication shops to large enterprises.

PowerFab is the sweet spot for fabricators that already use Tekla Structures for detailing/design, or that want a well-integrated system for detailing-to-fabrication. For example, a 30-person steel shop doing detailing in-house could use Tekla Structures for drawings and Tekla PowerFab for everything after design.

Tekla PowerFab’s Features and Capabilities

Tekla PowerFab is essentially a suite comprising Tekla EPM (FabSuite), Tekla EPM Go, and Trimble Connect for collaboration.

PowerFab’s key capabilities include:

- Estimating: A comprehensive estimating module to build quotes from scratch or from models. It supports a database of standard labor hours and costs for various connection types and piece types, and can import BOMs from CAD models or CSV. Estimators can adjust and apply costs, then produce polished proposals.

- Project Management: Tracks the status of projects and lots within projects, including issuing production orders, tracking what’s released to the shop, what’s delivered to site, etc. It provides project-level dashboards for progress and material status.

- Inventory and Purchasing:PowerFab handles inventory control of steel and parts, tracking heat numbers, remnants, and automatically updating stock when pieces are cut. The purchasing module ties in, generating POs for required materials with suggested quantities. Barcoding can be used for material receiving and picking.

- Production Scheduling and Tracking: Tekla EPM has a production control module that can schedule fabrication sequences (cut, weld, paint, etc.) and record progress. It may not have a visual Gantt but uses status codes/percent complete for each phase. Tekla EPM Go is the web interface that allows shop or field workers to view and update info on tablets/phones. For example, a welder can mark an assembly complete via EPM Go, and it updates the main system in real-time. EPM also can integrate with Trimble’s shop machinery (and others) for production data import.

- Integration with Tekla Structures: Perhaps PowerFab’s biggest edge is that it connects seamlessly with Tekla Structures (the 3D BIM software). A steel detailer can export a Tekla model’s data (through an IFC or direct integration) to Tekla EPM, populating all the piece marks, lengths, profiles, etc. This greatly streamlines the workflow from detailing to fabrication management. Revisions can also be updated from model changes. Additionally, Trimble Connect (a collaboration platform) ties in to share model views and status with other stakeholders.

- Labor Tracking and Quality: The system can log who worked on each piece and maintain QC records. It can generate labels and travelers with barcodes for each part.

- Fabrication visualization: A noteworthy feature for project managers monitoring large jobs is when using Tekla Model data, PowerFab can visualize fabrication status in 3D (color-code a model by fabrication progress).

- Reporting: A rich set of reports: production schedules, material requirement lists, labor productivity, project profitability, etc.

Tekla PowerFab is a comprehensive fabrication MIS, with a particularly strong design-to-fabrication data flow if you’re a Tekla user.

Tekla PowerFab’s Pricing

Trimble doesn’t publicly list Tekla PowerFab prices.

It’s typically sold as a subscription. Some sources indicate Tekla PowerFab might be priced by module or package. For example, Tekla EPM (core) plus Tekla EPM Go (mobile) could be one subscription bundle, and Trimble Connect might be separate. There is also likely an initial implementation service cost.

In short, expect enterprise pricing. Likely tens of thousands per year for a full suite for a mid-size shop, with smaller shops possibly in the low five-figures range annually, but evidence suggests that cost is still a barrier for many small steel businesses.

Who is Tekla PowerFab built for and what are its Use cases?

Tekla PowerFab provides “complete fabrication management for steel fabricators” with real-time info, and that it uniquely connects the model to the shop floor.

Tekla PowerFab is ideal for steel fabricators who:

- Create their own steel designs/detailing. If a fab shop does modeling in Tekla Structures, using PowerFab, they can output CNC files, BOMs, and manage changes easily.

- Medium-sized and growing. A 50-150 employee fab company building steel frameworks for buildings, who needs tight cost control and scheduling to deliver on large contracts, would benefit. For instance, a company fabricating and erecting structural steel for commercial buildings can use Tekla for design, PowerFab to manage fabrication and track pieces, and integrate with field via Trimble Connect.

Tekla PowerFab’s Pros

Comprehensive: Tekla PowerFab consolidates multiple fabrication management processes into one platform. It covers estimating, inventory, production, and even site deliveries. This is convenient for maintaining data consistency.

Seamless Tekla Integration: Perhaps the biggest pro, if you model your projects in Tekla Structures, PowerFab will streamline info from design to execution. This eliminates manual entry of BOMs and reduces errors, as the fabricator can base everything on the actual 3D model data.

Real-Time Visibility: PowerFab provides up-to-date information on production and material status, which aids decision-making. Managers can see what’s done, what’s in progress, and what’s delayed in near real-time.

Integration Ecosystem: Beyond Tekla models, PowerFab interfaces with other Trimble and third-party solutions. For example, it can connect to Trimble’s Robotic Total Station data for erection status, or feed into Trimble’s project management tools. It also supports standard formats like IFC and DSTV, making it interoperable with non-Tekla detailing and various CNC machines (through modules or partner solutions like SigmaNEST)

Tekla PowerFab’s Cons

Steep Learning Curve: Tekla PowerFab/EPM requires time for users to become proficient. It’s comprehensive, which means complexity. Even experienced estimators often struggle to use all features and end up bypassing some. It’s likely not as intuitive for someone without training, especially compared to newer apps.

Dependent on Drawings/Models: To get the most out of Tekla PowerFab, you ideally feed it engineering info (models, CNC data). If a fabricator doesn’t have a 3D model (say they get 2D plans from an external engineer), they must manually input or use spreadsheets for a thorough estimate, which can be frustruating. In short, it shines in a Tekla-centric workflow but is less special outside that.

Cost for Small Shops: Tekla PowerFab is not cheap. Though pricing is opaque, it can be assumed that the software can be expensive for small businesses, given its extensive features. A small 10-person fab shop might find it hard to justify the subscription and training costs relative to their revenue, especially if they won’t use half the features. Trimble’s enterprise sales approach might also be less flexible for tiny clients.

Partial Adoption/Process Change Needed: Some online feedback indicates that shops rarely use 100% of Tekla PowerFab’s capabilities. They might still fall back to spreadsheets for unique tasks. That means either the software doesn’t cover a niche need or the users didn’t fully adapt their processes. Small companies often have unique tribal processes that a big system expects you to standardize. If PowerFab can’t accommodate easily, users may circumvent it, undermining its value.

Issues with Custom Projects: Some online reviews suggest that Tekla PowerFab may not handle custom fabrication (non-structural items like custom stairs, railings with complexity) with nuance. Online reviewers reported that for miscellaneous jobs they still often resort to simpler methods (like spreadsheets) because EPM’s logic is built around standard piece types. So for a fab shop doing a lot of bespoke artistic metal or complex small assemblies, PowerFab might be rigid.

Tekla PowerFab VS EZIIL: Which one is better for small custom steel fabricators

The learning curve and complexity of Tekla PowerFab are major strikes against it for small teams. EZIIL Starter, being designed “beginner friendly, no steep learning curve”, can get a team on board much faster.

A 15-person shop likely doesn’t have an IT department or a dedicated software champion. They need something the owner, the foreman, and the project manager can all grasp without weeks of training. EZIIL’s interface and modular approach shine here.

Cost-wise, for a small steel shop, EZIIL is certainly a lot more budget-friendly option than Tekla PowerFab.

Also, EZIIL doesn’t force a detailing software choice. If a shop gets drawings in any format, they can use EZIIL to manage the job. Tekla might implicitly push a shop to use Tekla Structures (a costly software itself $20k/year for a couple of seats) to fully utilize PowerFab. Many small fab shops actually get drawings from third-party engineers and might not have any 3D model, for them, Tekla PowerFab’s main selling point is moot. They’d pay for a bunch of features they might not use.

EZIIL, conversely, is project-management-first and doesn’t require a fancy CAD backend. Tekla PowerFab, however, might offer deeper functionality.

Additionally, if a small shop plans to scale up and do large projects requiring extremely granular traceability or automated machines integration, Tekla’s enterprise-grade features might outstrip EZIIL (which is focused on simplicity and may not cover some advanced scenarios yet).

To sum it up. EZIIL is to Tekla PowerFab what a nimble speedboat is to a big ship. EZIIL can be deployed and maneuvered quickly by a small crew, whereas Tekla is a big vessel offering more capacity but needing a larger crew and preparation. For a small fabricator who values agility, ease, and low overhead, EZIIL is the more pragmatic choice. Tekla PowerFab is a fantastic but heavy tool, which can be an overkill for the little guys.