Excel once gave you just enough control, but as orders pile up, a single “job shop scheduling Excel” file turns into a stress-filled maze of formulas, macros and last-minute edits. Miss one cell and you’re expediting weldments, paying overtime, and trying to explain late deliveries to customers. That’s the moment you know your fabrication scheduling Excel workflow has hit its ceiling.

Still wrangling your entire shop on a colour-coded spreadsheet?

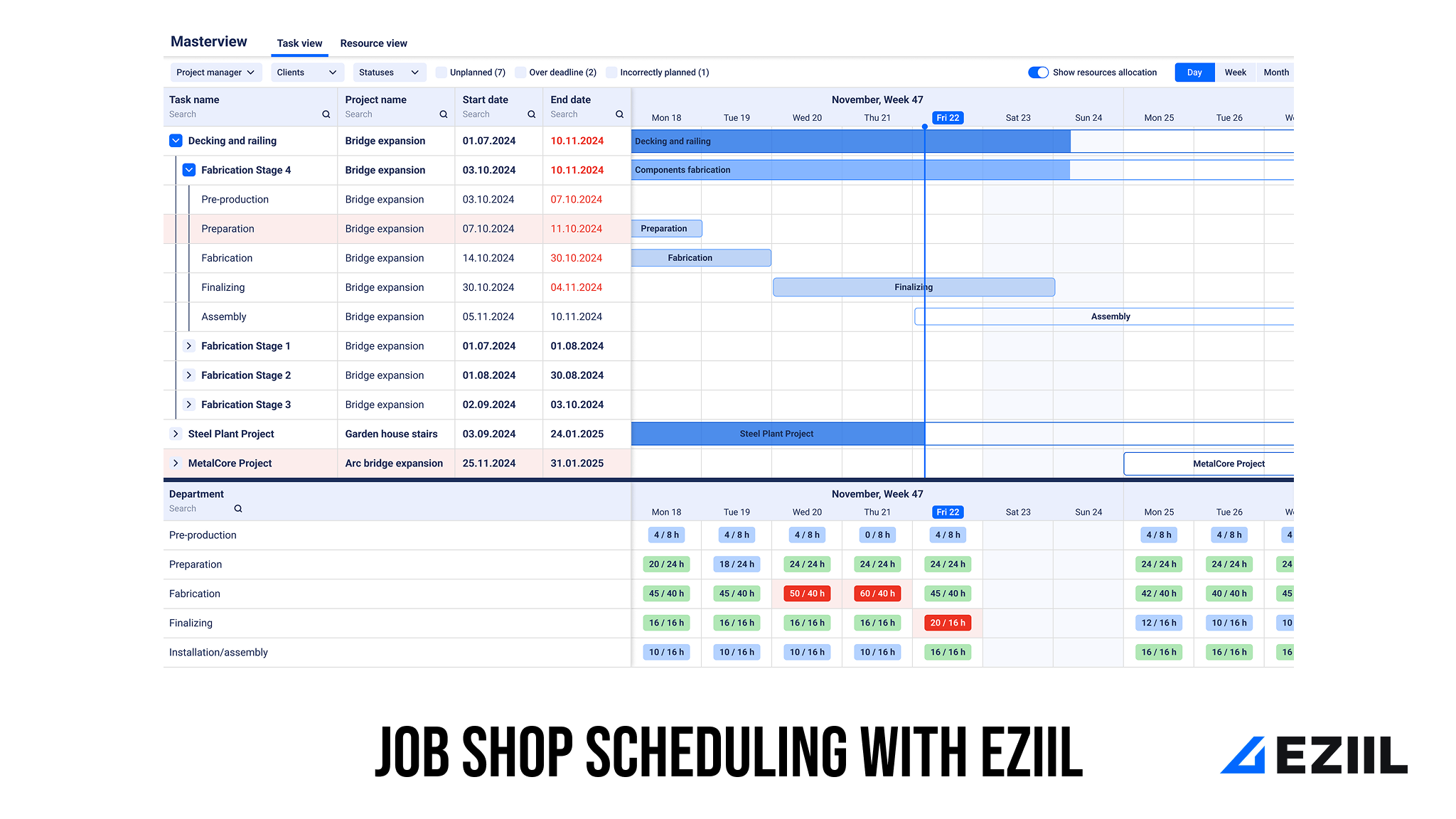

This article walks you through five unmistakable warning signs, each drawn from the daily frustrations we hear from growing metal fabricators, and shows how job shop software for metal fabrication like EZIIL Starter eliminate job shop scheduling Excel file chaos with:

Smart capacity planning that auto-balances workloads instead of forcing you to guess available machine and welder hours.

Real-time shop-floor progress so every stakeholder works from a single source of truth, not a static print-out.

Drag-and-drop visual scheduling that ripples changes through every downstream task in seconds.

By the end, you’ll be able to spot whether your steel fabrication job shop scheduling Excel tracker is quietly costing you money, and you’ll see the path to reclaiming on-time delivery and profitability. Ready for a quick health check? Let’s dive in.

Sign #1: Constant fire-fighting and expedite chaos

When your entire shop depends on a single job shop scheduling Excel sheet, even the smallest tweak can trigger a chain reaction of chaos. The problem with Excel is that it keeps the latest schedule locked inside a single static file. When the scheduler tweaks a ship date, the shop floor is still staring at yesterday’s print-out and purchasing never sees the change.

One of our customers summed up their experience with Excel, before adopting EZIIL, perfectly: “It was a matter of doing everything manually, checking procurement and workshop delays daily”. The result is a frantic game of telephone, emails, calls, and sticky notes, to tell everyone what really needs to get done first.

Key symptoms you’ll recognise:

Rising expedite freight and vendor rush fees

A backlog dominated by “hot jobs” instead of planned flow

Deadlines missed or renegotiated at the last minute, eroding customer trust

Overtime spikes as the team hustles to catch up

Why Excel can’t cope: Spreadsheets have no built-in logic for capacity or dependencies, so a single change forces you to hunt through dozens of tabs and linked files, exactly what a manufacturing job shop scheduling Excel template was never designed for.

- No real-time visibility. A file on a desktop (or even in SharePoint) can’t broadcast updates across departments.

- Zero capacity logic. Excel doesn’t auto-flag when a welder, press brake, or paint booth is double-booked, so clashes surface only after it’s too late.

- Version sprawl. “Final-_v7-UPDATED.xlsx” lives beside three older copies. Nobody is sure which one is right.

How EZIIL Starter ends the chaos:

| Excel limitation | EZIIL Starter fix |

|---|---|

Updates live in a static spreadsheet Updates live in a static spreadsheet |  Cloud-based single source: everyone, from scheduler to welder, sees the same live board on any screen Cloud-based single source: everyone, from scheduler to welder, sees the same live board on any screen |

Priority changes travel by email Priority changes travel by email |  Drag-and-drop Gantt instantly pushes new sequences to every workstation. No re-typing dates Drag-and-drop Gantt instantly pushes new sequences to every workstation. No re-typing dates |

Capacity bottlenecks discovered late Capacity bottlenecks discovered late |  Built-in capacity engine auto-checks labour hours and flags overloads before you promise the job Built-in capacity engine auto-checks labour hours and flags overloads before you promise the job |

Progress tracked verbally Progress tracked verbally |  Mobile reporting feeds real-time completions back into the plan, so the board is always current Mobile reporting feeds real-time completions back into the plan, so the board is always current |

Sign #2: job shop scheduling Excel Version-control nightmares

Excel’s dirty secret is that it creates multiple truths. The “final” production schedule sits on the scheduler’s desktop, the maintenance supervisor keeps an older copy on a USB, and the shop floor works from yesterday’s print-out because Wi-Fi drops in the welding bay. One production manager told us bluntly: “Before EZIIL we relied on Excel just for job tracking, it lacked a proper production scheduling structure, so every change meant re-printing sheets. Now I just push the task and changes to EZIIL board and the team opens it on-screen.”

Key symptoms you’ll recognise

Conflicting ship dates on different spreadsheets. Nobody sure which one is right

Two supervisors quote different ship dates for the same job

Rework or scrap because the shop cut to an obsolete revision

Hours lost to “Is this the latest?” phone calls instead of value-adding work

Why your job shop scheduling Excel fuels the nightmare

- File sprawl: every email births a new copy; USB sticks and desktops multiply the confusion

- Single-user locks: one person leaves the file open, everyone else is frozen out of updates

- No audit trail: you can’t see who changed Column G, or roll back the damage

- Offline print culture: the moment the sheet hits the printer, it’s already out-of-date

How EZIIL Starter restores a single source of truth

| Excel limitation | EZIIL Starter fix |

|---|---|

Endless “FINAL_v9” copies Endless “FINAL_v9” copies |  Cloud-based live board: one schedule, always current Cloud-based live board: one schedule, always current |

No version history No version history |  Automatic change log and role permissions show who changed what, when Automatic change log and role permissions show who changed what, when |

File locks and email attachments File locks and email attachments |  Concurrent multi-user editing with auto-sync; no file locking Concurrent multi-user editing with auto-sync; no file locking |

Stale print-outs Stale print-outs |  Shop-floor tablets/mobile dashboards display the latest priorities. Zero paper Shop-floor tablets/mobile dashboards display the latest priorities. Zero paper |

Sign #3: Zero real-time job shop visibility

When production updates live on whiteboards and paper tickets, managers fly blind until the next stand-up meeting. Until that data is typed back into the production schedule template Excel sheet, no one knows what’s actually finished or which workstation just stalled.

Key symptoms you’ll recognise

Operators finish a task but the schedule isn’t updated until end-of-shift, so bottlenecks surface too late

Quoting accuracy slides because actual vs planned hours are invisible

Last-minute overtime and weekend work become the default “fix” for surprise delays

Customers call asking for status you can’t verify without walking the floor

Why your job shop scheduling Excel keeps you in the dark

- Manual data capture: progress is written on paper or shouted across the bay, not streamed into the file

- Lagging plan-vs-actual insight: you can’t spot a slipping task until someone re-keys timesheets

- No alerting: spreadsheets don’t ping you when a job sits idle for two hours

- Hidden labour overruns: real hours stay buried in timesheets, so future quotes stay wrong

How EZIIL Starter turns the lights on

| Excel limitation | EZIIL Starter fix |

|---|---|

Progress entered hours (or days) later Progress entered hours (or days) later |  Shop-floor tablets/mobile dashboards update task status the moment work starts or finishes Shop-floor tablets/mobile dashboards update task status the moment work starts or finishes |

Managers hunt for paper travellers Managers hunt for paper travellers |  Live dashboards show plan-vs-reality by job, department, or machine in one click Live dashboards show plan-vs-reality by job, department, or machine in one click |

No early-warning system No early-warning system |  Automatic alerts flag stalled tasks and delays in projects in real time Automatic alerts flag stalled tasks and delays in projects in real time |

Guesswork in quoting and scheduling/planning future projects Guesswork in quoting and scheduling/planning future projects |  Historical actuals feed back into your planning and scheduling, sharpening future bids Historical actuals feed back into your planning and scheduling, sharpening future bids |

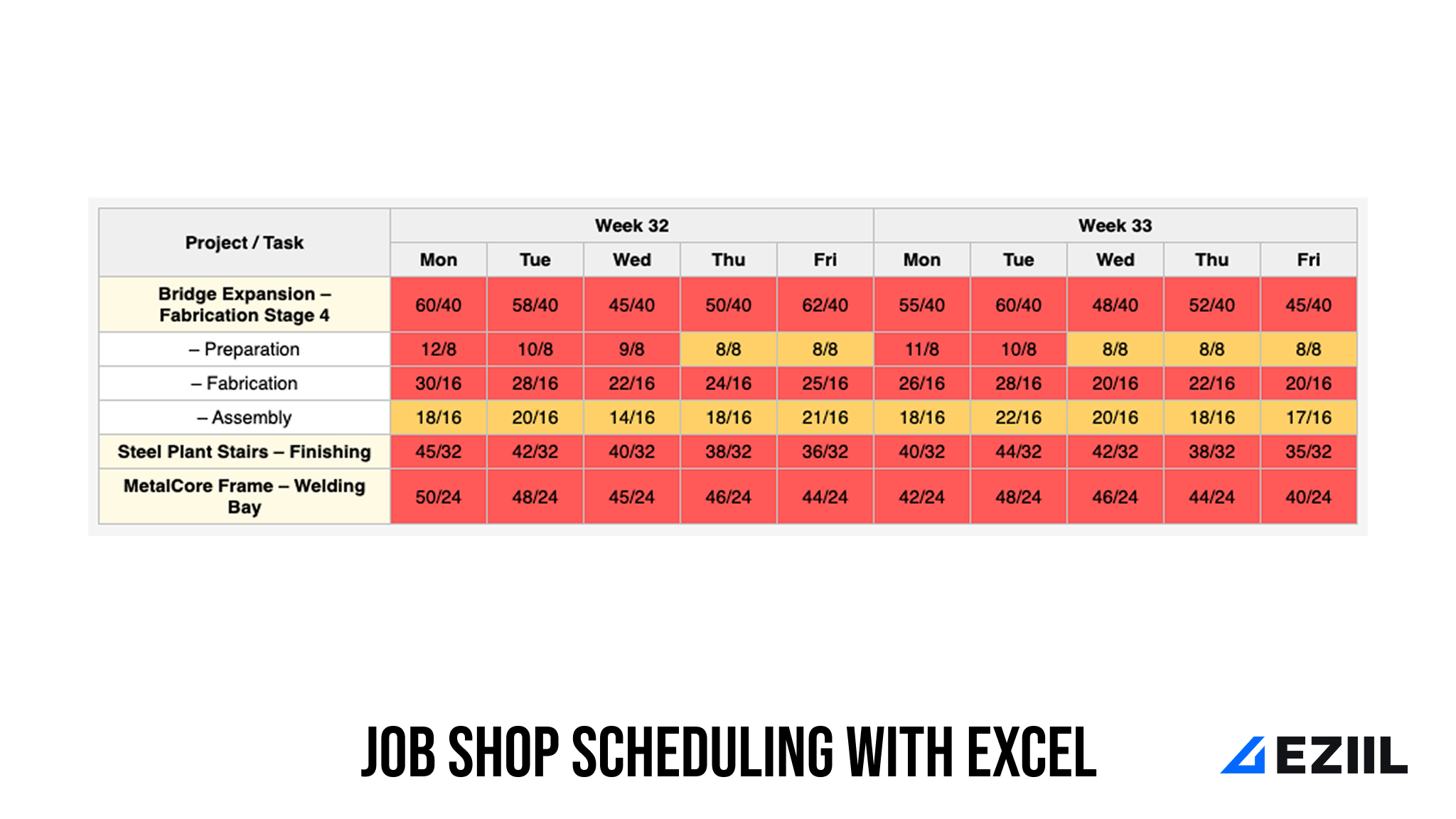

Sign #4: Manual capacity balancing breaks down

Growth means new machines, more quotes and extra shifts…and a fragile Excel workbook that can’t keep them in sync. Fabricators tell us their biggest headache is dynamic capacity planning: the moment material is late or a welder calls in sick, hours of spreadsheet tweaking follow, and the plan still ends up wrong.

Key symptoms you’ll recognise

One department drowns in overtime while another sits idle

Pivot charts that look balanced, until an operator phones in sick

Quotes mis-priced because planned hours don’t match real available hours

Late-night rescheduling marathons, hoping tomorrow’s plan won’t clash

Why your job shop scheduling Excel can’t keep capacity balanced

- Static math: formulas show hours vs. capacity, but nothing auto-rebalance when resources change

- Siloed views: separate tabs for cutting, welding, paint, assembly hide cross-department overloads

- Clumsy what-ifs: scenario testing means copying the file (“Plan_B-v5.xlsx”) and rebuilding every pivot

- Hidden overloads: red cells appear only after you’ve already broken the plan

How EZIIL Starter keeps the load level

| Excel limitation | EZIIL Starter fix |

|---|---|

Manual pivot charts Manual pivot charts |  Visual heat-map planner highlights overloads by hour, day, or week. No formulas Visual heat-map planner highlights overloads by hour, day, or week. No formulas |

Single-shift view Single-shift view |  Multi-shift, multi-department capacity engine auto-distributes work across people and shifts Multi-shift, multi-department capacity engine auto-distributes work across people and shifts |

Slow re-allocation Slow re-allocation |  Drag-and-drop levelling instantly reschedules tasks when a resource is unavailable Drag-and-drop levelling instantly reschedules tasks when a resource is unavailable |

Guesswork in quoting Guesswork in quoting |  Actual vs. planned capacity analytics flow straight into future estimates Actual vs. planned capacity analytics flow straight into future estimates |

Sign #5: Project complexity exceeds flat rows and columns

Structural-steel jobs rarely flow in a neat linear line. They break into phases, spawn change-orders, and drag a bill of materials (BOM) that morphs daily. Things that are hard to manage and align with a static grid.

Key symptoms you’ll recognise

Copy-pasting multi-level BOMs into endless tabs, hoping formulas don’t break

Change-orders lost or applied late, triggering re-work and wasted steel

Purchasing errors because the schedule and BOM live in separate files

No way to see how a delay in blasting affects paint and final assembly downstream

Why your job shop scheduling Excel crumbles under complexity

- One-dimensional grid: flat rows and columns can’t model assemblies, sub-assemblies, phases, and tasks in a hierarchy

- No relational links: schedules, BOM, drawings, and revisions exist in siloed sheets, manual effort glues them together

- Hidden dependencies: shifting one milestone never alerts connected tasks or sister projects

How EZIIL Starter tames complex projects

| Excel limitation | EZIIL Starter fix |

|---|---|

Static flat sheet per project Static flat sheet per project |  Hierarchical project → phase → task structure with collapsible levels and Gantt view. Perfect for dynamic multi-stage steel jobs Hierarchical project → phase → task structure with collapsible levels and Gantt view. Perfect for dynamic multi-stage steel jobs |

Manual cross-sheet updates when plans change Manual cross-sheet updates when plans change |  Dependency engine and Smart capacity planner: a change-order in Phase 1 auto-ripples to every linked phase, workload estimate and purchase list, keeping the entire schedule accurate Dependency engine and Smart capacity planner: a change-order in Phase 1 auto-ripples to every linked phase, workload estimate and purchase list, keeping the entire schedule accurate |

Drawings scattered in other files Drawings scattered in other files |  Manage data in one place: attach blueprints, QC images and other documents; materials link straight to tasks for traceable Excel-free revision control Manage data in one place: attach blueprints, QC images and other documents; materials link straight to tasks for traceable Excel-free revision control |

EZIIL Starter vs Job Shop Scheduling Excel: Calculate your monthly savings

Eziil Starter ROI Calculator

Users

FAQ

Why do steel fabricators outgrow job-shop scheduling Excel templates?

Spreadsheets hold static data. As orders pile up, planners must re-enter dates, chase version conflicts and eyeball over-capacity rows. Fabricators tell us, “Excel lacks a proper scheduling structure” and forces daily expediting calls.

What is production planning with Excel in a steel-fabrication job shop?

Production planning with Excel means building Gantt-like tables, capacity pivots and colour-coded status columns manually. It works for a handful of projects, but every new part number or change-order demands copy-paste edits and extra worksheets—quickly turning spreadsheets into a fragile “single point of failure.”

What KPIs signal my fabrication scheduling Excel file is hurting delivery?

Watch for rising rush-freight fees, overtime spikes, missed promise dates and constant status-meetings. These bottlenecks indicate that your business might have outgrown Excel’s capacity for job shop scheduling.

How does job shop scheduling software improve on-time delivery versus a “job shop scheduling Excel” file?

A dedicated MES like EZIIL Starter recalculates capacity the moment you drag a bar on the Gantt. Operators report progress on tablets, giving managers instant bottleneck alerts. With Excel you discover overruns only after the shift ends. Customers see the difference as on-time delivery rises 15-30 %.

Can I just download a better fabrication scheduling Excel template instead of new software?

Templates add colour-coding and macros but still rely on manual updates and single-user locks. They can’t auto-balance load across shifts or broadcast changes to the shop floor. Upgrading to EZIIL Starter typically saves your whole team time and money worth far more.

Why is production planning with Excel risky for steel fabrication projects?

Spreadsheets can’t track real-time load, resource conflicts or change-orders. As soon as one cell changes, every downstream task, BOM line and purchase date is out of sync—leading to overtime, expedite freight and missed delivery dates. Purpose-built job-shop scheduling software, like EZIIL, keeps a live, capacity-aware plan that updates automatically.