Production Scheduling

What is Production Scheduling?

Production Scheduling is the process of planning when each step of production will occur and which resources (machines or workers) will perform it, in order to meet delivery deadlines.

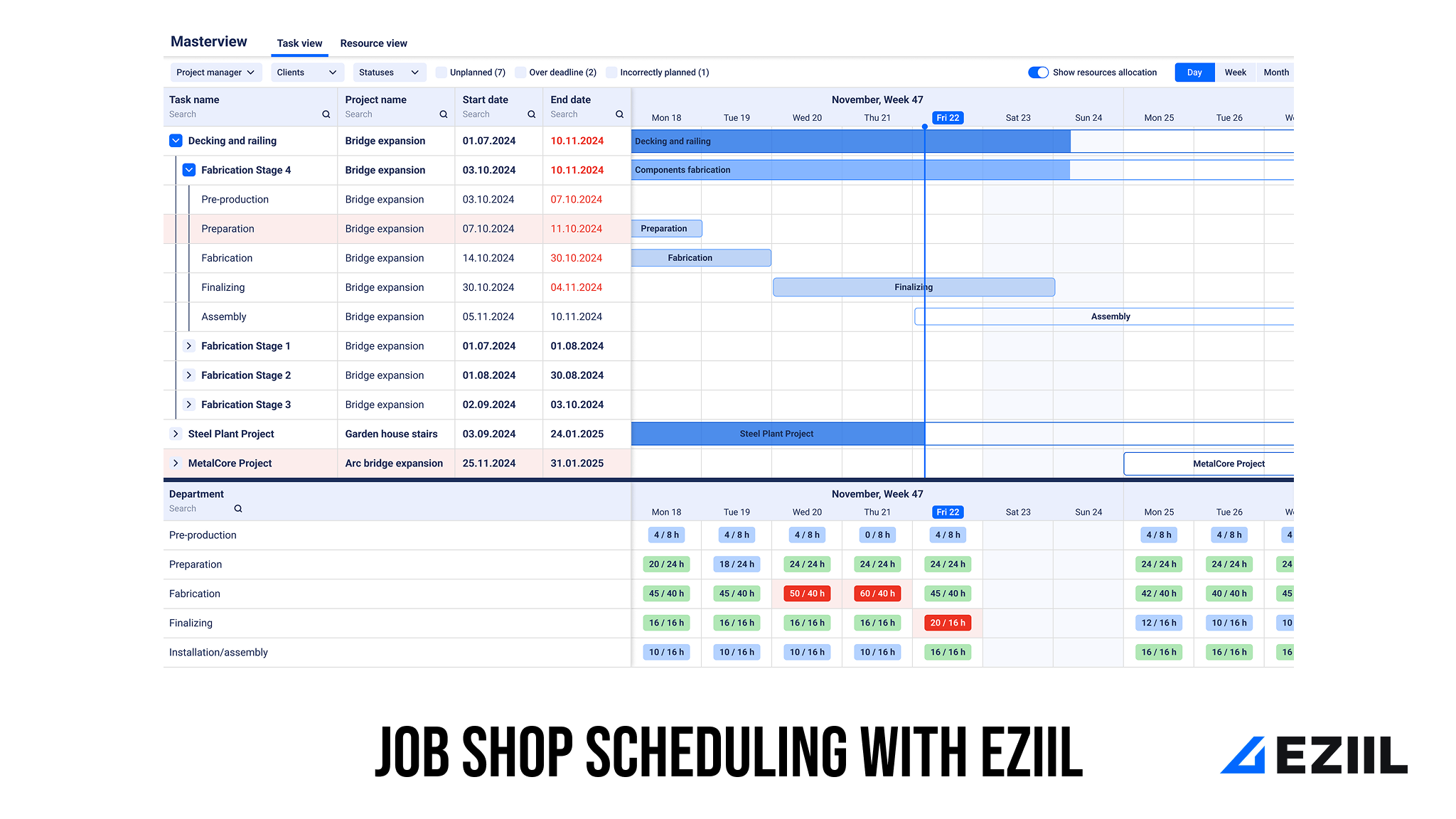

In terms of steel fabrication, production scheduling means creating a timetable (often a Gantt chart or a calendar) that slots jobs into limited machine time and labor shifts without overbooking. Unlike routing (the “where/how”), scheduling answers “when and with which resources” each job runs.

A production schedule takes into account machine availability, worker capacity, and due dates to allocate job orders into a timeline.

Good scheduling coordinates multiple projects, streamlines utilization, and quickly adapts to changes (such as rush orders or a machine breakdown). Finite scheduling (considering actual capacity constraints) is especially crucial in a 20-person job shop where one delayed cutting operation can ripple through all downstream work.

Effective production scheduling yields on-time deliveries, balanced workloads, reduced overtime, and the ability to promise realistic lead times to customers.