Material Takeoff (MTO)

What is Material Takeoff (MTO)?

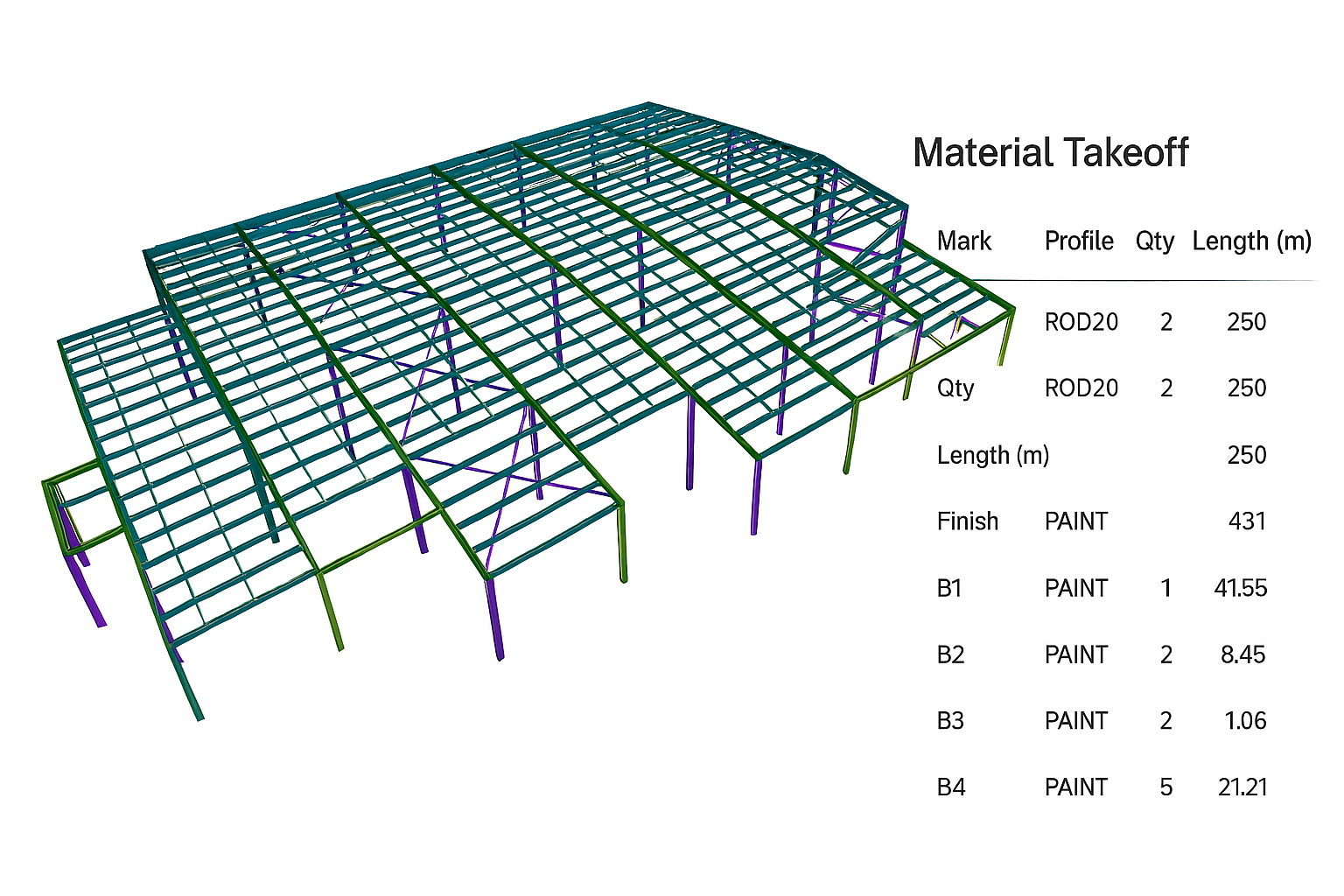

A Material Takeoff (MTO) is the process of extracting the quantities and types of materials from design drawings or models to generate the Bill of Materials (BOM) for a project. MTO provides an accurate picture of material requirements before work begins.

For small steel fabrication shops, an accurate material takeoff is vital to staying competitive and profitable. Because small businesses often work with limited resources and tight budgets, so missing even a few items in a quote can be the difference between a profitable job and a loss.

A complete MTO guarantees that the bid covers all required materials, so the shop isn’t caught off guard by extra costs later on. It also helps in getting the purchasing right (ordering exactly what’s needed and in time).

Small shops cannot afford large material contingencies or last-minute rush orders, so the MTO enables them to plan material orders efficiently and possibly taking advantage of bulk discounts or coordinated deliveries.

An MTO includes every material component required for the project, broken down by type and quantity.

This typically covers:

Structural elements: the total length or tonnage of steel beams, columns, pipes, or lumber pieces needed.

Plates and fittings: the number of flange plates, brackets, or connection hardware.

Consumables and miscellaneous materials: pounds of welding wire, gallons of paint, bags of concrete, fasteners (nuts, bolts, screws), etc.

Any other project-specific materials: such as electrical cables, plumbing fixtures, or finishing materials. Basically everything visible on the drawings that must be provided to complete the build.

An MTO ties directly into your BOM and helps prevent costly shortages or excess stock during production. In fact, the output of the MTO process essentially becomes the BOM for the project. The MTO provides the raw information (the types and quantities of materials derived from the plans) which is then formatted into the BOM used by purchasing and project managers.

To sum it up, precise material takeoffs lead to better cost control, on-time project delivery, and minimal waste, all of which are critical for a steel project’s success.