EN 1090

What is EN 1090 in steel fabrication?

EN 1090 is a series of European standards that set the rules for how steel and aluminium structures are fabricated and assembled. It sits under the EU Construction Products Regulation and is the basis for CE marking structural components placed on the EU market.

The three main parts are: EN 1090-1 (conformity assessment and CE marking), EN 1090-2 (technical requirements for steel structures) and EN 1090-3 (technical requirements for aluminium structures).

In practice, EN 1090 defines how you control materials, welding, cutting, assembly, inspection and documentation so that the finished structure has the required mechanical resistance, stability and durability.

Why EN 1090 matters for custom steel fabricators

If you fabricate load-bearing components that become part of a building or civil structure in the EU or EEA, EN 1090 compliance and CE marking are normally mandatory. Without it, many general contractors simply cannot buy from you, especially on EXC2 projects like industrial halls, mezzanines, platforms or stairs.

For small steel fabricators, EN 1090 is often the ticket to bigger, more profitable work: it proves you can trace materials, welds and people, and that your factory production control (FPC) is under control.

Best practices for EN 1090 compliance

Define which Execution Classes (EXC) you work in (often EXC2) and build your procedures, training and documentation to match.

Keep material certificates, welding records, inspection reports and release documents in one place, linked to each project and assembly.

Standardize project “audit packs” so every job has the same minimum documentation before it ships.

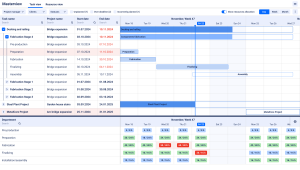

Use software like EZIIL to link certificates, material batches, operations and person-task logs into one EN 1090 traceability chain, and export everything in a few clicks when an auditor or client asks.