Arc Welding is a fundamental and widely used welding process that enables the fusion of metals by utilizing the intense heat generated from an electric arc. This method plays a crucial role in joining diverse materials, contributing to the construction of everything from towering skyscrapers to intricate machinery.

As one of the most versatile welding techniques, arc welding encompasses various methods, each with distinct attributes tailored to different applications and materials.

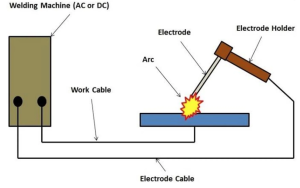

In arc welding, a connection is established between a consumable or non-consumable electrode and the workpiece, forming an electrical circuit. When an electric current flows through this circuit, an arc is ignited, creating a controlled and extremely hot focal point. This heat effectively melts the electrode and the adjacent area of the base metal, enabling them to merge upon cooling and solidification.

What is the Arc in Welding?

The “arc” in welding refers to the electric discharge that occurs between an electrode and the workpiece when an electric current passes through them. This arc generates intense heat, which melts the electrode and the base metal, creating a molten pool that solidifies upon cooling and forms a welded joint.

In welding, the arc is the essential heat source that produces the necessary energy to fuse metals together. The heat generated by the arc is extremely hot, often reaching temperatures upwards of 6,000 degrees Celsius (10,000 degrees Fahrenheit). This high temperature is what allows the metals to melt and fuse, creating a strong and continuous bond.

Here’s a simplified breakdown of how the welding arc works:

Electrical Circuit: A welding power source provides an electric current. When an electrode is connected to the positive terminal and the workpiece (usually made of metal to be welded) is connected to the negative terminal, an electrical circuit is completed.

Arc Formation: When the electrode is brought close to the workpiece, but not in contact with it, and then lifted slightly, an electric arc is established. The voltage difference between the electrode and the workpiece causes a spark to jump across the gap, creating the arc.

Heat Generation: The electric arc generates intense heat due to the resistance of the air between the electrode and the workpiece. This heat is focused on a small area, which causes the metals to reach their melting points.

Metal Melting and Weld Pool Formation: The heat generated by the arc causes the electrode and a portion of the base metal to melt. This creates a molten pool of metal.

Solidification: As the weld pool cools and solidifies, the melted electrode and base metal bond together, forming a continuous and strong welded joint.

What is Sub Arc Welding?

Submerged Arc Welding (SAW) or Sub Arc Welding is a widely used and highly efficient welding process that involves joining metals by creating a fusion between them using an electric arc. What makes this method distinct is the way it employs a layer of granular flux to shield the welding arc and the molten metal from the surrounding atmosphere. This process is particularly suited for welding thick sections of materials, especially steel, and it offers several advantages in terms of speed, productivity, and quality.

In Submerged Arc Welding, the arc is concealed beneath a layer of flux, which serves multiple critical functions. This granular flux not only shields the arc and molten metal from airborne contaminants that can cause welding defects, but it also regulates the heat distribution, preventing excessive distortion or warping of the welded components. Moreover, the flux melts to form a protective slag that covers the welded area as it solidifies, safeguarding the weld from oxidation and enhancing the final weld’s mechanical properties.

Book a 60-minute demo to see

how eziil mrp solution works for you

What is sub-arc welding used for?

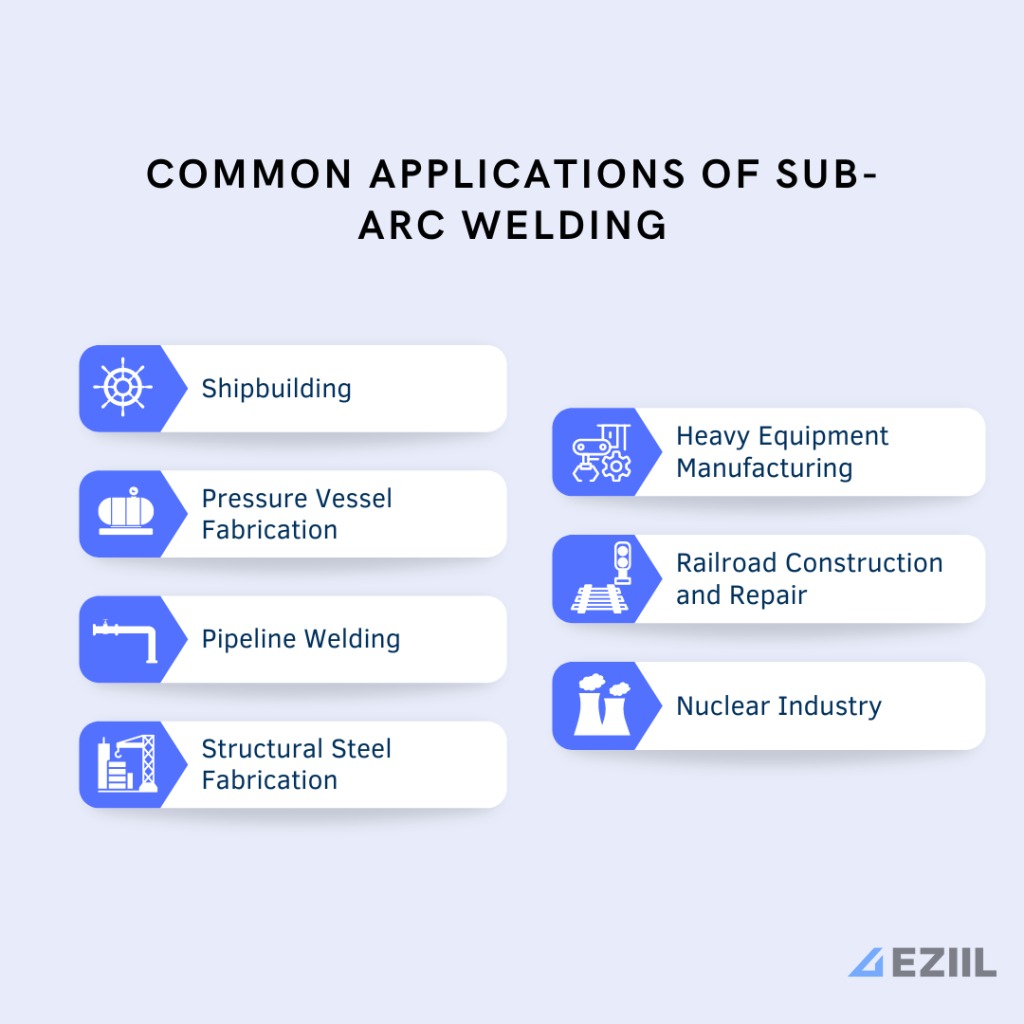

Submerged Arc Welding (SAW), often referred to as sub-arc welding, is a specialized welding process that finds its primary applications in heavy industries that require efficient and high-quality welding of thick materials. It offers unique advantages that make it well-suited for specific types of projects. Sub-arc welding is commonly used in the following areas:

Shipbuilding: Sub-arc welding is frequently employed in the shipbuilding industry to join large metal components, such as hulls, decks, and other structural elements. Its high deposition rates and deep penetration capabilities make it ideal for creating strong, durable welds in the thick steel plates used in ship construction.

Pressure Vessel Fabrication: The construction of pressure vessels, used in various industrial applications like chemical processing, petrochemical plants, and power generation, demands welds with high integrity to withstand extreme pressures and temperatures. Sub-arc welding’s ability to create deep, full-penetration welds with consistent quality makes it a preferred choice for these critical applications.

Pipeline Welding: For the construction of pipelines, particularly those transporting oil, gas, and other fluids, sub-arc welding is utilized to create strong and reliable welds that can endure the demanding conditions of buried or underwater pipelines. The high productivity of the process is advantageous in large-scale pipeline projects.

Structural Steel Fabrication: Sub-arc welding is used in the fabrication of structural steel components for buildings, bridges, and other infrastructure projects. It can efficiently join thick steel sections, providing the necessary strength and stability for these structures.

Heavy Equipment Manufacturing: Industries that manufacture heavy machinery, such as cranes, mining equipment, and construction machinery, often require strong welds for load-bearing components. Sub-arc welding’s ability to penetrate thick materials and produce uniform, high-quality welds makes it suitable for these applications.

Railroad Construction and Repair: Sub-arc welding is employed in the fabrication and repair of railroad tracks, where sturdy welds are essential to ensure the safety and reliability of the tracks.

Nuclear Industry: The nuclear industry requires high-integrity welds for components used in nuclear reactors and other critical systems. Sub-arc welding’s capability to produce deep welds with minimal defects is advantageous in this sector.

While sub-arc welding offers numerous benefits in terms of productivity and weld quality for these specific applications, it may not be the optimal choice for thinner materials due to its high heat input and potential for distortion. As with any welding process, proper training, equipment setup, and procedure adherence are crucial to achieving successful and reliable welds.

Submerged Arc Welding Advantages and Disadvantages

Submerged Arc Welding (SAW) offers several advantages and disadvantages, which are important to consider when selecting the appropriate welding process for a specific application. Here’s a breakdown of the advantages and disadvantages of submerged arc welding:

| Advantages | Disadvantages |

|---|---|

| High Deposition Rates: SAW has high deposition rates, making it efficient for welding large components and structures, reducing overall welding time. | Limited to Thick Materials: SAW is most effective for thicker materials and may not be suitable for thin sections due to its high heat input. |

| Deep Penetration: SAW can achieve deep penetration into thick materials, producing strong, full-penetration welds. | Complex Setup: SAW requires specialized equipment for flux handling, wire feeding, and arc control, which can be more complex to set up compared to other processes. |

| Consistent Quality: SAW is highly automated and controlled, resulting in consistent and uniform weld quality, which is particularly important for critical applications. | Lack of Visibility: The granular flux layer can obscure the weld pool and joint, making it difficult to visually monitor the welding process. |

| Shielding and Protection: The granular flux layer shields the weld from atmospheric gases, preventing oxidation and contamination, and creates a protective slag layer that enhances weld quality. | Potential for Porosity: If the flux is not properly applied or if the workpiece surface is not cleaned thoroughly, the process can be susceptible to porosity in the weld. |

| Reduced Fume and Spatter: The flux layer minimizes welding fumes and spatter, creating a safer and cleaner working environment. | Initial Flux Costs: The cost of the flux used in SAW can contribute to the overall welding expenses. |

| Versatility in Materials: SAW is suitable for a wide range of materials, including carbon steel, stainless steel, and some high-alloy materials. | Less Suitable for Out-of-Position Welding: While SAW is versatile, it is generally less suitable for out-of-position welding (vertical and overhead) due to potential slag inclusion. |

| Positional Flexibility: SAW can be performed in various positions, allowing for welding complex structures and components. | Limited to DC Polarity: SAW typically uses DC polarity, which might require adjustments for certain applications that benefit from AC welding. |

| Economical for Large Welds: High deposition rates and productivity make SAW economical for welding large components and structures. | Environmental Considerations: Proper handling and disposal of used flux materials are necessary to minimize environmental impact. |

| Reduced Distortion: Controlled heat input and deep penetration contribute to reduced distortion and warping of the base material. | |

| Less Heat-Affected Zone (HAZ): Deep penetration reduces the size of the heat-affected zone, improving mechanical properties and reducing the risk of cracking. |

Summary

In conclusion, the submerged arc welding (SAW) process presents a valuable and efficient technique for welding applications that demand high-quality, deep-penetration welds in thick materials. Throughout this report, we have explored the various aspects, advantages, and disadvantages of SAW, shedding light on its significance in heavy industries and critical applications.

The advantages of SAW are clear, as its high deposition rates, deep penetration capabilities, and consistent weld quality make it a preferred choice for projects involving large components, structural fabrication, pressure vessel construction, and pipeline welding. The ability to create strong, uniform welds while minimizing fume and spatter emissions enhances both productivity and worker safety.

When choosing submerged arc welding, it’s essential to carefully evaluate the advantages and disadvantages based on the specific project requirements, material properties, and desired weld quality.