You would not attempt to bake a new batch of holiday cookies without a recipe, nor should you try to manufacture something from scratch without completing a bill of materials or build of materials (BOM). A BOM is sometimes called an assembly component list, and it is a vital step in the manufacturing and supply chain processes. It is crucial in inventory, material requirement planning, scheduling, and production.

This is why manufacturers should have this essential document completed before starting production. Like a food recipe informs a baker, the bill of materials tells a manufacturer what is in their product and how much of it they must have on hand.

Here is what you should know about what is BOM, the advantages it offers your company, the various types of BOM you will find, and a few examples.

What does the BOM (Bill of material) mean?

Many define a BOM as a comprehensive inventory of the raw materials, assemblies, subassemblies, parts, components, and quantities required to manufacture a product. It is a critical function of the manufacturing business that companies will refer to during a product’s lifecycle, starting at the design stage and continuing through manufacturing, erection, and maintenance.

Because the BOM is a master structure for everyone in the manufacturing process and a central part of an efficient manufacturing operation, managing it should include following the BOM explicitly. Observing it is the best way to ensure that everyone in the organization is onboard and understands what is required at each manufacturing stage.

That is why the BOM lists each raw material in detail, avoiding misunderstandings at various production stages. Each team is responsible for multiple stages of the manufacturing process, and those in charge of manufacturing should be in constant communication with suppliers.

Learn more about how to make a BOM!

What are the advantages of BOM?

A BOM makes the manufacturing process precise and well-organized. Having one offers the following benefits for the production process:

- Handover from sales to production: This is an important step before the production process. The draftsman ensures that all is clear and can be produced, and all materials are clearly defined, ensuring that nothing is lost between handing over from sales. This is a final check before the actual purchase and production process starts.

- Feedback for estimator: in bespoke structural productions, only 1 of 10 deals is won, so the first estimation is an approximate BOM. Still, the draftsman will make it more specific, which is valuable input for the estimator if he considers all that was needed.

- Shows availability: A BOM provides a separate list of materials and their quantities, which is critical for purchasing and inventory management teams.

- Plan purchases of raw materials: A BOM helps forecast each component, making orders as accurate as possible. BOM must also be divided into executable steps to produce construction steel projects. Projects are massive, and products are needed based on construction plans. This helps producers to divide financial investment into raw material and save warehouse and production space.

- Enhances transparency: The bill of materials offers everyone a framework to follow, helping to simplify complex processes and providing transparency.

- Reduces waste: An accurate bill of materials optimizes stock levels. Companies order the correct amount of stock to meet production schedules or fulfill forecasted sales, reducing the capital tied up in inventory and the associated carrying costs.

- Improves efficiency along the supply chain: A BOM helps improve efficiency along the supply chain since when items are delivered on time, the risk of delays to production, servicing, or sales order completion is drastically reduced.

Still, other advantages include:

- Staying alert to materials shortages that result in downtime and expediting charges

- Identify the cause of a product failure

- Quickly replace faulty components

- Find issues in software components

- Ensures that third-party contract manufacturers use efficient and accurate production methods

- BOMs assist companies that run lean production and continuous improvement-based processes

Bill of material formats

A Bill of Materials is typically for a specific product or assembly and has a hierarchical structure with the finished product at the top. It includes part numbers, quantities, units of measure, descriptions, costs, and additional specifications.

The most common formats for a BOM are the single-level BOM, multi-level structure, and the flattened part list:

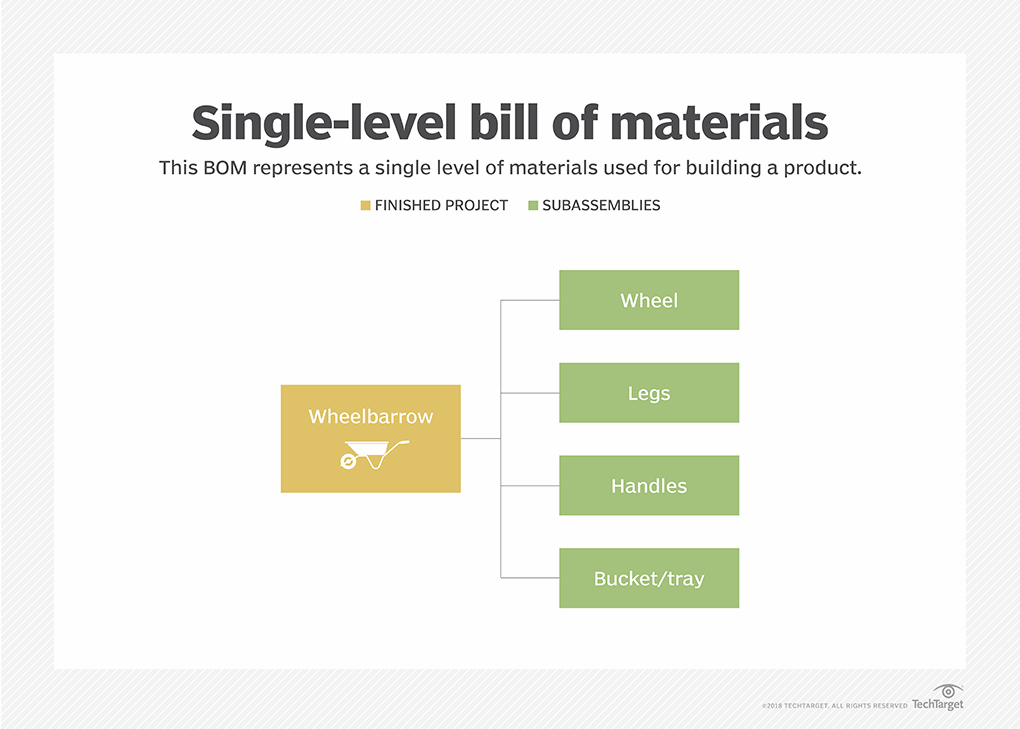

Single-level part list

A single-level bill of materials is a simple option that shows the parts, materials, and assemblies presented without sub-levels. Although this BOM is the easiest to create, it is insufficient for complicated products since it does not indicate the relationship between parent and child parts or assemblies and subassemblies. It also makes it challenging to determine which part needs to be replaced or repaired in new products.

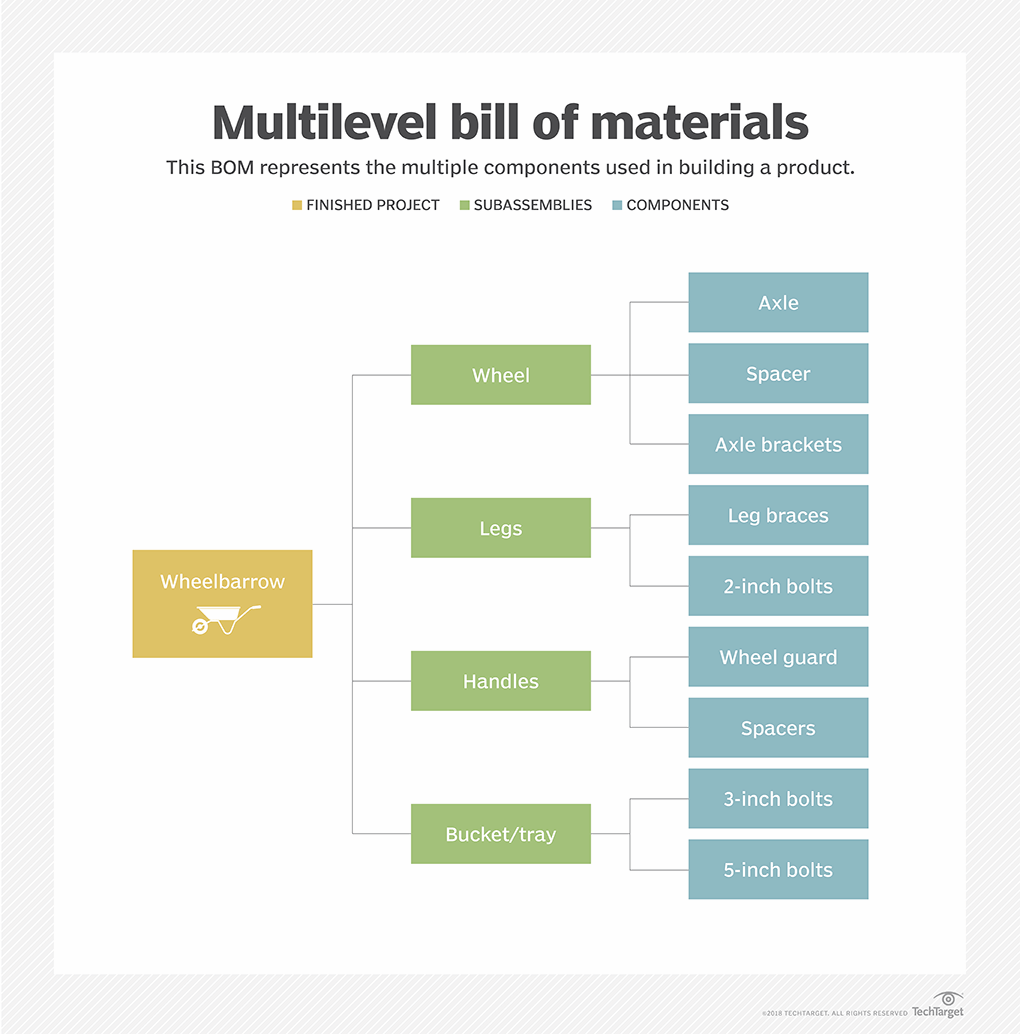

Multi-level format

The multi-level BOM is popular since it’s more comprehensive than the single-level. It allows the user to present all items and corresponding sub-levels for assemblies and sub-assemblies. Also, the BOM typically includes dynamically presented levels, allowing drilling down to unlimited sub-levels when necessary.

The multi-level format requires more effort to create. Still, it offers more details and specifics on the parent and child product relationships and between assemblies and subassemblies.

Flattened part list

Another valid BOM format, the flattened part list, is a “flat” list of items from multiple levels with their corresponding quantities. The format helps purchase and plan with its relatively simple list of components and quantities.

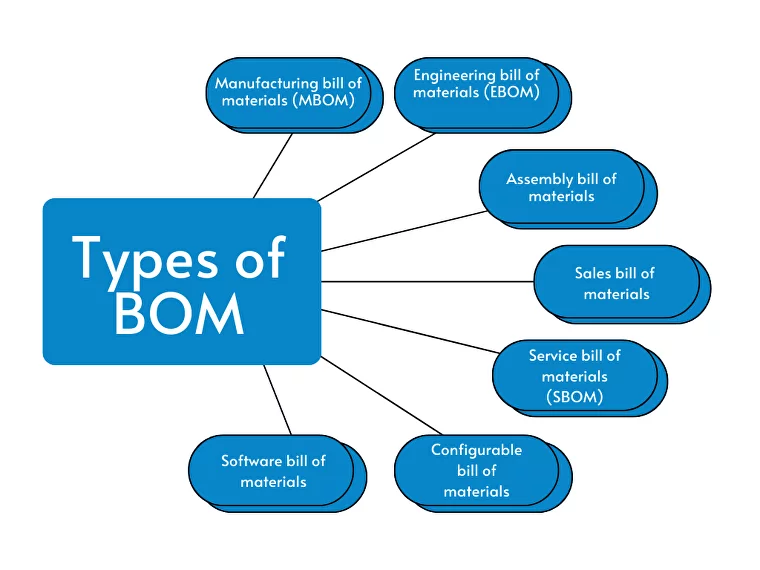

Types of bill of materials

Bills of materials come in several different types. What type is used depends on the industry and product life cycle. For example, producing multi-story buildings requires a manufacturing bill of materials (MBOM), but doesn’t need a service bill of materials (SBOM).Here are some of the most common types of BOM’s:

- Manufacturing bill of materials (MBOM): The MBOM includes a structured, comprehensive list of items and subassemblies needed to produce a finished product. It also provides information on the individual items, how they relate to one another, assembly instructions, and parts that require processing before assembly.

- Engineering bill of materials (EBOM): An engineering bill of materials defines the parts, assemblies, and parts from the engineering department’s perspective. It typically provides details, including specifications, materials, tolerances, and standards. The engineering BOM shows the component structure and includes a mechanical or technical drawing of a product.

- Assembly bill of materials: The assembly BOM is a list of items required to assemble the finished product and is usually less complicated than an MBOM.

- Sales bill of materials: The sales BOM shows the items assembled at the sales phase and sold as a single sales item.

- Service bill of materials (SBOM): The SBOM is a list of items required to service an object, often machinery, equipment, or a product. It only contains information relevant to ordering the parts and servicing the equipment.

- Configurable bill of materials: Configurable BOMs meet unique customer specifications and indicate the building materials, labeling, and packaging materials. Configurable products include PCs, vehicles, and data center hardware or software.

- Software bill of materials: Software BOMs list the components of a piece of software, consisting of a mix of commercial and open-source products. They allow developers to ensure disparate software components work together and are up to date and protected from vulnerabilities.

Book a 60-minute demo to see

how eziil mrp solution works for you

In-depth Bill of Materials Examples

1. Contrasting the single-level and multi-level BOMs (Wheelbarrow)

The following single-level assembly BOM shows the finished product and subassemblies. It doesn’t say anything about quantities or components. This BOM format does not work with complicated products because the relationship between parent and child parts or assemblies and subassemblies is unknown.

In contrast, the multi-level BOM (below) details the components, making it easier to assemble the wheelbarrow.

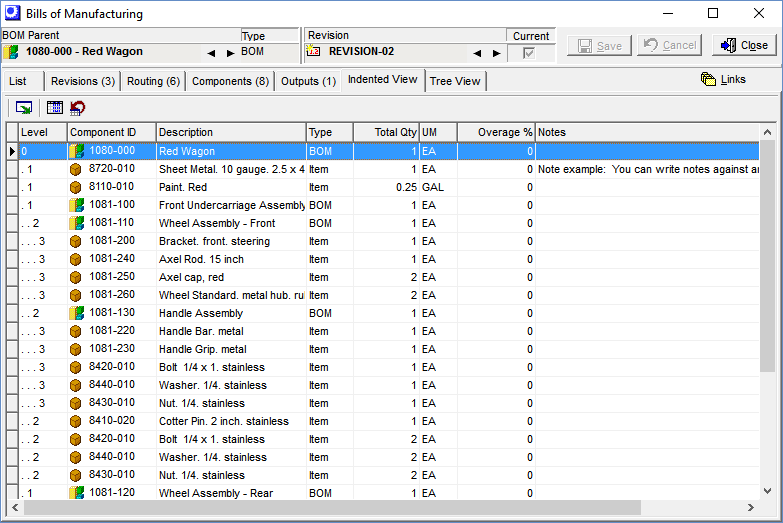

2. Multi-level manufacturing BOM (The Red Wagon)

The following BOM represents a multi-level bill of manufacturing with an indented view tab.

Under the “Level” column, the components in the BOM are all assigned to Level 1. If the Level 1 component is a subassembly or phantom assembly, those components are assigned to Level 2. If a Level 2 component is a subassembly or phantom assembly, its components are assigned to Level 3, and so on.

The “Total Qty” column signifies the total quantity required to make one unit of the BOM parent (in this case, a red wagon). In Level 1 components, this quantity equals the component’s usage quantity. In lower levels, the component’s usage quantity is extended using the following formula:

Component Usage Qty x Parent Component Total Qty = Component Total Qty.

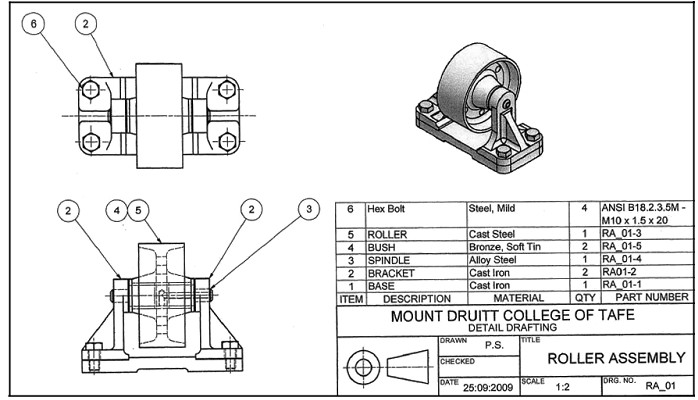

3. A BOM supporting engineering and manufacturing (Roller Assmebly)

An engineering BOM (EBOM) begins in the engineering department, often with computer-aided design (CAD) software. It is usually converted to a manufacturing BOM (MBOB) to support producing the product. Although there is typically some work to do to transform an EBOM into an MBOM, the MBOM will eventually direct material planning and product costing. The MBOM is usually maintained by an organization’s engineers or draftsmen in Excel spreadsheets or in ERP/MRP systems, depending on what tools are used internally.

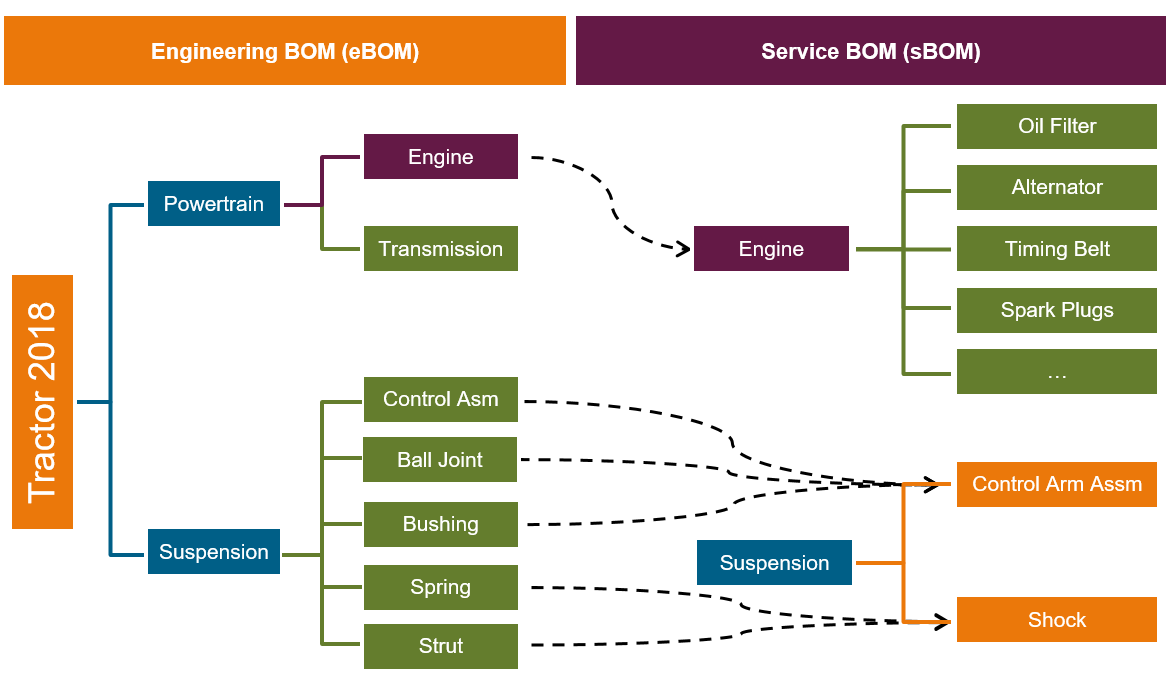

4. A service BOM linked to engineering (Tractor Engine)

A service bill of materials BOM (SBOM) is a managed view of the product’s serviceable parts. The SBOM represents a product with a defined set of OEM service-related definitions.

In addition to linking to the engineering definition, the Service BOM can also:

- Define other characteristics critical to service

- Manage specialized tooling required for assistance that could be sold as a service offering

- Include required serviceable items in the definition of purchased assemblies

- Define service kits to manage loose parts that will later be sold as service offerings

- Define and handle service assemblies to make servicing more efficient

- Manage compatible upgrades within the defined configurations

- Derive integrated parts catalogs in various formats, including interactive 3D

Summary

No matter what is the specifics of the BOM and who is using or in what industry, the most important is to know that BOM’s most crucial function is to bring clarity. In different stages of the product, everybody knows what was needed and how to do it.

There can be differences in how detailed the BOM info is or how systematized this management is based on the company’s internal regulations. Mainly it’s very flexible in a company’s starting phase, where the same people cover multiple job positions, having all the knowledge needed to execute a successful production project. At the start, there are usually not so many products.

The need for a precise and repeatable BOM increases when the company grows. Growth brings in more people to handle the specific role. For example, production and purchasing are operated by a different person, which brings a need to understand things similarly. Creating a clear and understandable BOM from every product produced is one efficient way to do it, so the customer gets exactly what he ordered on time.