What is a Bill of Materials?

A Bill of Materials or Build of Materials (BOM) lists all the required parts, items, materials, and processes to manufacture a product. Think of it as a recipe that details the components, quantities, and steps you will take.

A BOM could be a relatively simple document or a complex, multi-leveled product description from multiple sub-assemblies. It might cover a minor assembly or significant machinery and equipment consisting of many smaller BOMs.

BOMs can have multiple purposes, including their use as a picklist of production items and their ability to serve as a valuable tool for costing finished products.

EBOM vs. MBOM

Two subgroups of BOMs used in manufacturing are EBOMs and MBOMs. Here’s how they differ:

EBOM stands for engineering Bill of Materials because engineers typically use them when designing a product in computer-aided design (CAD) systems. Engineers organize the EBOM based on a CAD drawing, and it spells out the design of the finished product, including any alternative parts and part numbers from the drawing notes.

Each line of the EBOM includes essential information such as description, quantity, part name, part number, product code, part revision, unit of measure (UOM), and other specifications or features of the product.

On the other hand, the manufacturing Bill of Materials (MBOM) is the document showing all the parts and assemblies required to create a finished product. It is vital in designing enterprise resource planning (ERP) systems and materials requirement planning (MRP).

MBOMs include more details than EBOMs since they must provide a line for each part or assembly from the supply chain and instructions for their use. For instance, the product you are building requires ten fasteners, and each type is listed in the MBOM, along with the subassembly where it will be used. However, the EBOM will only include a line listing the ten fasteners.

Because the MBOM is the document your shop will use to build the product, it should be accurate, organized, detailed, and up-to-date, including a list of all components, how to use them, and where to procure them.

How to make bill of materials?

Making a detailed BOM can be time-consuming, but it can make your manufacturing process more efficient, so don’t rush through it. Before building the BOM, answer the following questions

- What are you building? You should at least be in the design phase of your project to start preparing an accurate BOM.

- How will you manage the BOM? Establish a system for ensuring you are using the latest version. Allow only a few people to edit the BOM to avoid confusion.

- Who will use it? Determine which departments will use the BOM during production, so you know what information to include.

- What information will you include in the BOM? Make your BOM as detailed and complete as it needs to be.

- How will you organize it? Decide how many levels and sub-assemblies your document will have and how you’ll group the items.

- What program will you use to create it? Many organizations prefer ERP solutions because edits are made system-wide, ensuring everyone has the latest version in real-time. An effective BOM includes a fail-proof system ensuring the newest version is always accessible.

What are the necessary elements?

If your BOM is going to be accurate and detailed, it should include the following elements:

- BOM level: BOMs sometimes have multiple levels, each representing either the primary assembly or a sub-assembly. Assign a number to each part or group to indicate where it fits in the hierarchy of the BOM. The level makes it easier for users to understand the structure and navigate the document.

- Part number: Each item should have a unique part number to prevent confusion and ensure everyone within the manufacturing cycle identifies and uses the correct parts.

- Part name: Each part or assembly must include a detailed and unique manufacturer name to help anyone identify the part without cross-referencing other sources.

- Description: Many BOMs also provide a comprehensive description to help distinguish parts from similar items. Descriptors could be dimensions, colors, or other specifications.

- Quantity: The number of parts needed is crucial information for the BOM. Keep this up to date so you can take advantage of bulk purchasing.

- Unit of measure: The BOM should show what unit of measurement you use, such as ‘each,’ ‘ounces,’ ‘millimeters,’ or ‘ounces.’ Specifying these units can prevent costly mistakes.

- Procurement type: Listing the procurement type specifies how you buy and obtain the part. Typically, it will show whether the part is purchased off-the-shelf or custom-made according to project specifications.

- Phase: It could be helpful to include space marking where the parts are in their lifecycles. Designations include ‘in production,’ ‘testing,’ and ‘in design.’ Doing this helps keep track of your project’s progress.

- BOM notes and comments: Including notes is not essential, but additional information that doesn’t fit in other categories can go here to increase the efficiency of the project.

What else to include in BOM to make it more effective?

You could add even more detail if it helps simplify the process. Other elements could include:

- Lead time: The time required to complete the manufacturing process

- Scrap factor: The percentage of scrap

- Done criteria: The steps needed to assemble the components

- Rollup cost: An estimate of the total amount you have to spend

Any details you include will depend on the type of project and what you think is needed to provide a comprehensive bill of material.

BOM examples

Taking the time to create a Bill of Materials is essential. It’s a comprehensive list of materials, assemblies, components, and other critical items that manufacturers depend upon to build a product, so it must be detailed and accurate.

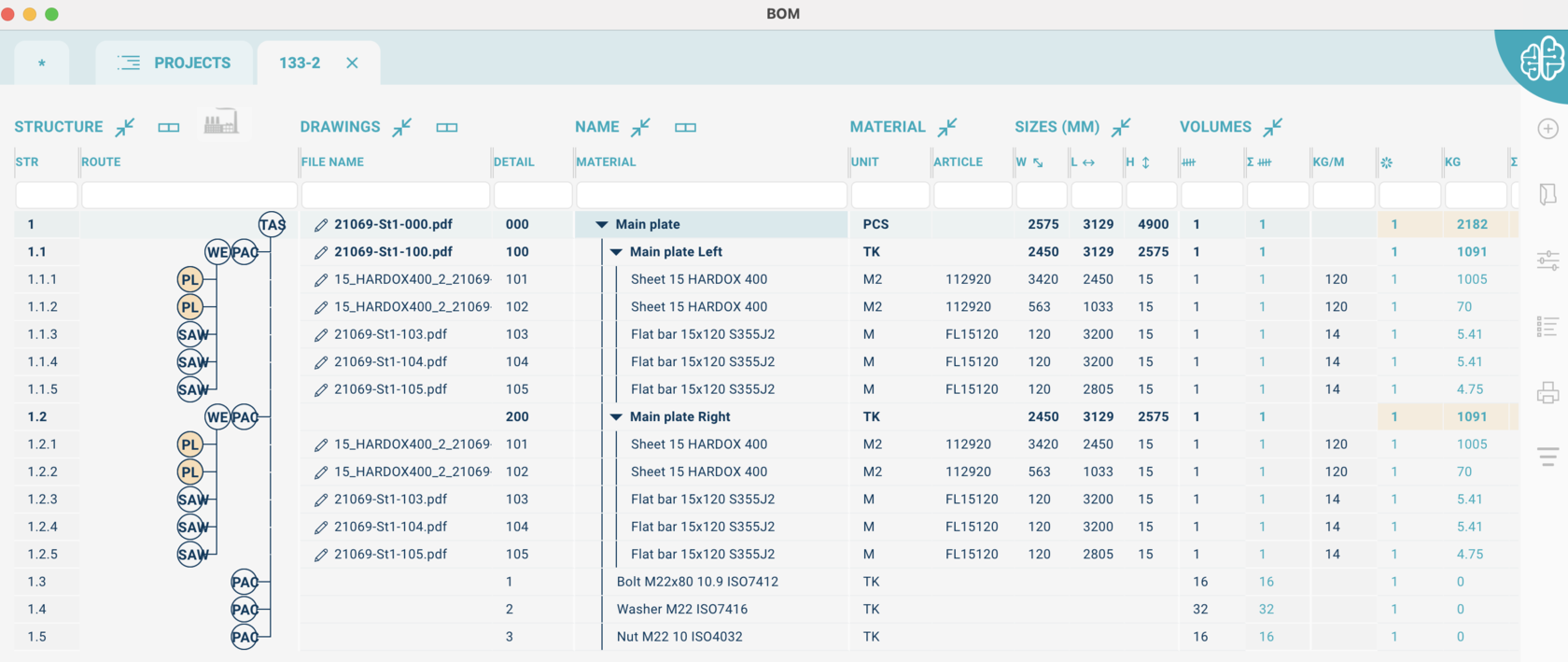

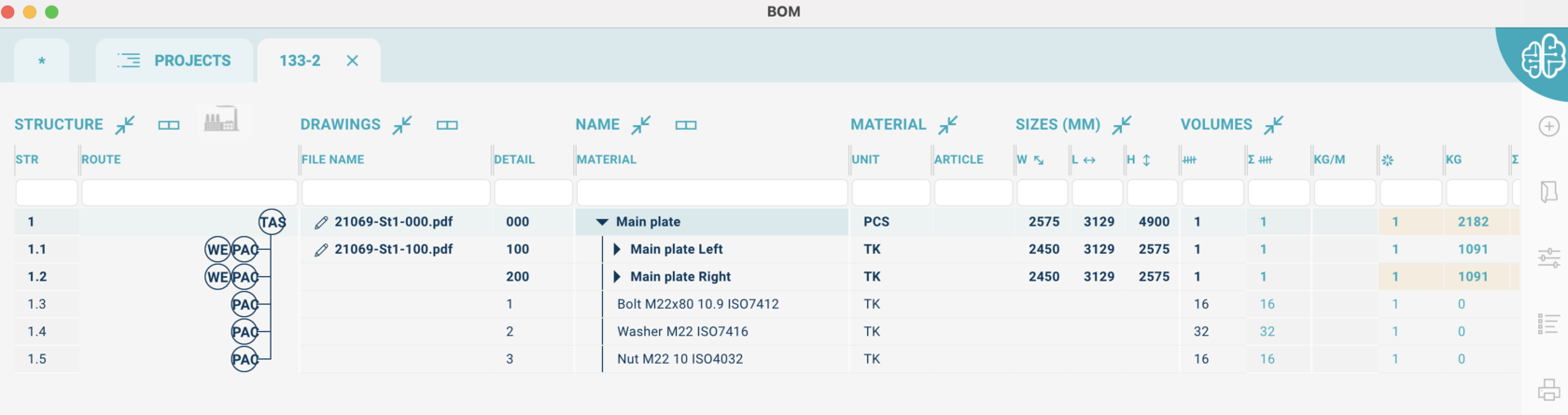

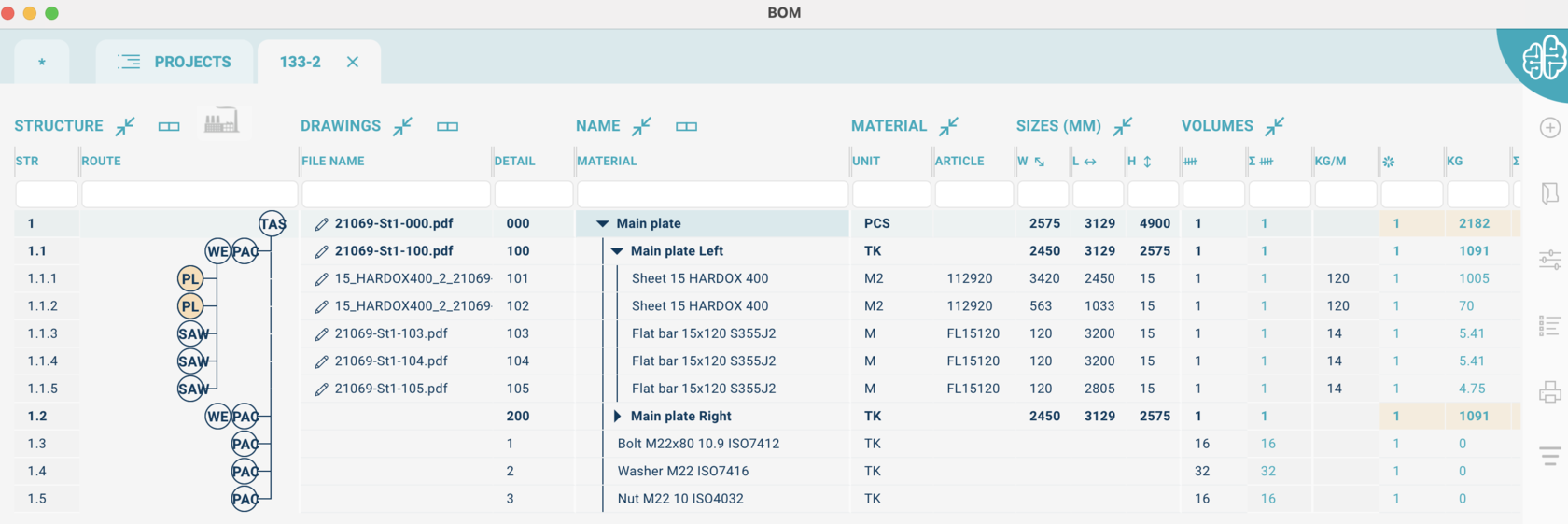

The BOM below is a relatively straightforward document containing the elements required to manufacture Main plate.

BOM for Main plate includes Main plate Left, Main plate Right, Bolt, Washer and Nut.

BOM for Main plate Left includes 2 lines of Sheet material with different measures and 3 lines of Flat bar with different measures.

BOM for Main plate includes BOM for Main plate Left, BOM for Main plate Right, Bolt, Washer and Nut.