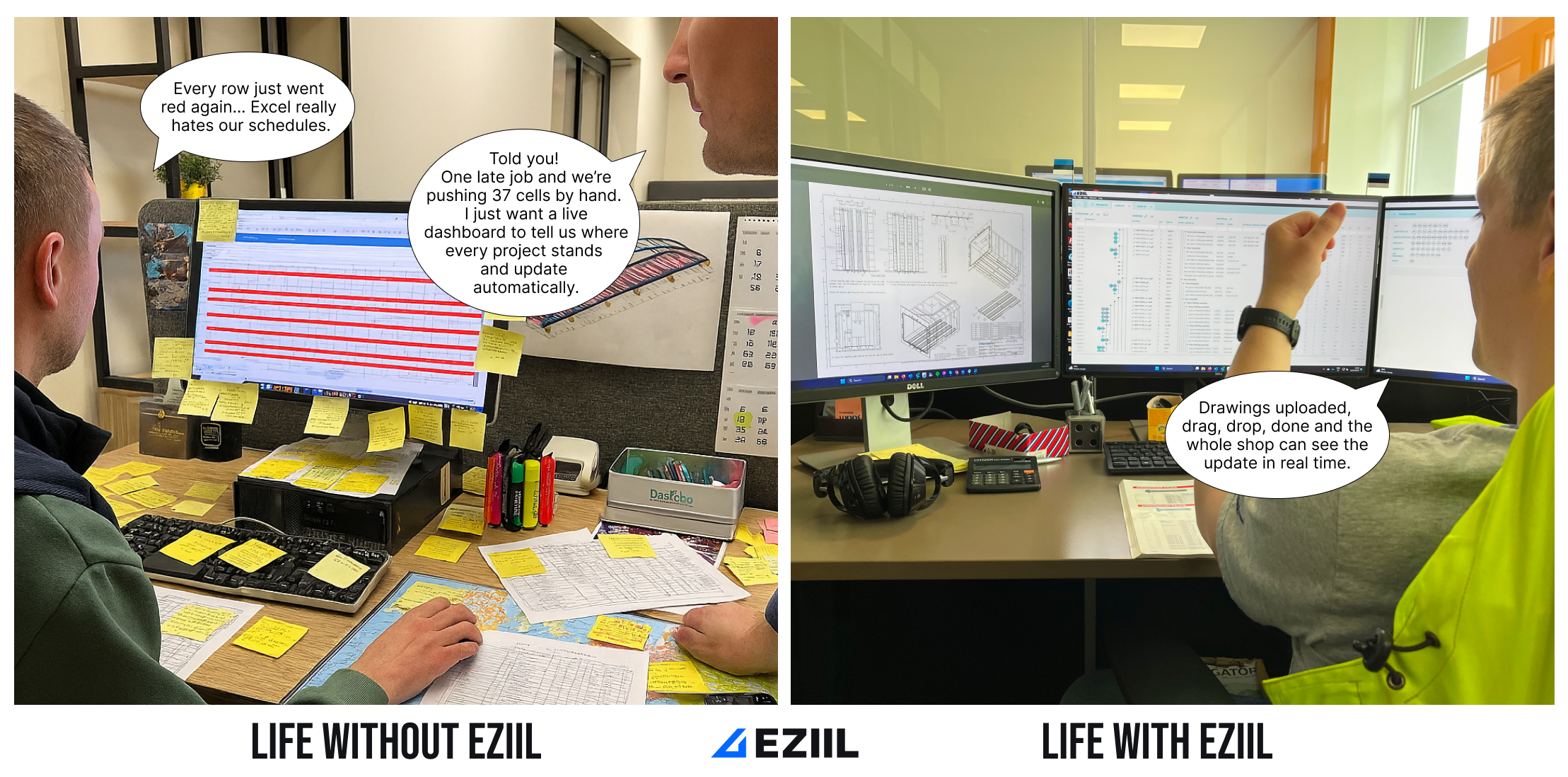

In many small custom steel fabrication shops, project management still runs on a patchwork of disconnected tools. Excel spreadsheets for scheduling, paper printouts on the shop floor, email chains for change orders, and even sticky notes with updates on planners’ desks.

This DIY approach may have worked when the business was tiny, but as projects pile up it becomes nearly impossible to get real-time status updates, leading to production bottlenecks, missed deadlines, and chaotic firefighting. Critical information ends up scattered across multiple files (or reliant on the supervisor’s memory), making it tough for the team to know what’s actually happening in real time. This is exactly where EZIIL Starter comes in to help small custom steel fabricators get their shop under control.

In this article, you’ll learn about the 12 key pain points and reasons why small custom steel fabricators have chosen EZIIL Starter as their project management and execution solution over full-blown complex ERP’s and inefficient Excel sheets.

The State of Project Management in Custom Steel Shops

It’s no surprise that almost half of small custom steel fabricators still aren’t using a modern project management and execution (MES) system, they default to tools like Excel instead.

Spreadsheets feel familiar and flexible at first, but as customer demands rise and operations grow more complex, those same spreadsheets start creating more problems than they solve. They lack the structure, reliability, and real-time connectivity needed for a modern metalworking operation. What was once a quick fix can quickly become a liability: fueling inefficiencies, errors, and missed opportunities.

On the other hand, generic ERP systems promise to bring order, but they come with a hefty price tag and often overshoot the needs of a small job shop. Fabricators who have tried implementing big-name ERPs often find them overwhelming.

An EZIIL customer, who had previously trialed an ERP system, once told us that it nearly ground their entire operation to a halt for months and that they never used even half of the features they were paying for.

Full-suite ERPs meant for enterprise-scale manufacturing can require huge upfront investments, months (or years) of setup, and extensive training, all for functionality that a 20-person fabrication shop probably doesn’t even need.

So what’s the alternative?

Increasingly, custom steel fabricators are choosing EZIIL Starter. It’s a modern project management and Manufacturing Execution System (MES) built specifically for small custom steel fabricators to replace the Excel chaos and avoid the bloat of traditional ERPs. EZIIL focuses on the core project scheduling, tracking, and shop-floor needs without the complexity or high cost of a full ERP/MRP. It’s a lightweight, cloud-based solution that can be adopted at your own pace in phases and integrated with your existing tools.

In short, EZIIL is designed to tackle the fundamental pain points that small fabrication shops face day-to-day, while remaining simple enough that your whole team will actually use it.

Disconnected Systems (Excel, Pen and Paper, Emails)

One of the biggest struggles for small custom steel fabricators is information scattered across disconnected systems.

You might have job details in an Excel quote sheet, scheduling on a whiteboard, inventory on a Google Sheet, time tracking on paper cards, and emails flying back and forth for purchase orders and design changes. Nothing talks to anything else.

The result? Duplicate data entry, inconsistent information, and endless hunting for the “latest” update.

As one fabrication manager described, before EZIIL “we were chasing details across 10+ spreadsheets and email threads. If one thing changed, we’d have to update multiple files and hope everyone was looking at the right version.” It was a recipe for mistakes and frustration.

“Implementing EZIIL is the most successful digitalization project in our department. The whole team can now work in one system, and we deleted 12 different Excel sheets that we had to update every day.” – R. Kalda, Chairman at Enefit Solutions

How EZIIL Connects Custom Steel Projects from Top Floor to Shop Floor?

EZIIL eliminates these silos by centralizing all project info and tasks in one place. Instead of juggling disconnected files, tools and apps, your team logs into one platform where everything from project estimates and drawings to schedules and work orders is connected and up to date.

This creates a single source of truth. For example, when Enefit Solutions adopted EZIIL, they were able to retire a dozen separate Excel sheets and have their entire team collaborating in one system, saving them a significant amount of time and money. No more copy-pasting data from one sheet to another or losing critical notes in somebody’s notebook.

EZIIL unifies your data so nothing falls through the cracks. The payoff is immediate: less clerical work, fewer manual errors, and far less time spent cobbling together updates.

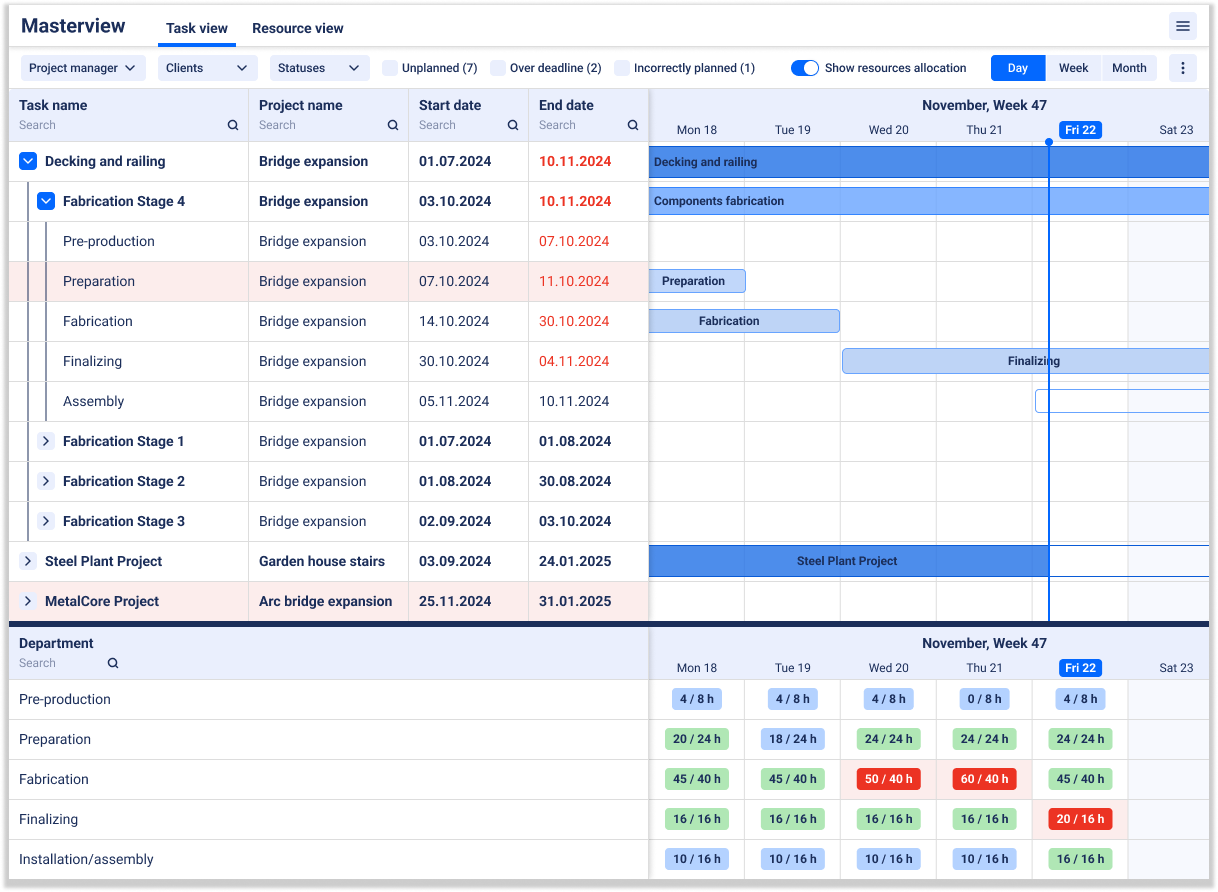

Overwhelm with Complex ERP Systems Built for Big Fabricators

Having recognized the limitations of spreadsheets, some fabrication shop owners consider full ERP/MRP systems, only to find that these come with their own set of headaches.

Traditional ERP systems can be overkill for a small custom fabrication shop. They are typically designed to handle enterprise-wide processes in large factories, with modules for everything from accounting and HR to procurement, inventory, production scheduling, and quality control.

While that sounds comprehensive, in practice a small custom steel shop usually doesn’t need (or cannot realistically maintain) many of those modules.

The result is feature overload, complexity and a big annual bill.

This isn’t an exaggeration. Small manufacturers often spend tens of thousands of dollars on ERP software and consulting, only to implement a subset of it. Implementation itself is a huge undertaking. Poor or incomplete ERP implementations are common with small custom steel fabricators, with many companies never fully utilizing the scheduling functionality they initially hoped for.

We’ve heard multiple stories of small fabrication shops where after six months of struggling with a complex ERP, the production team quietly went back to their Excel and whiteboard because the ERP was too cumbersome to use day-to-day. In the meantime, the company had sunk costs into software licenses and training with little to show for it.

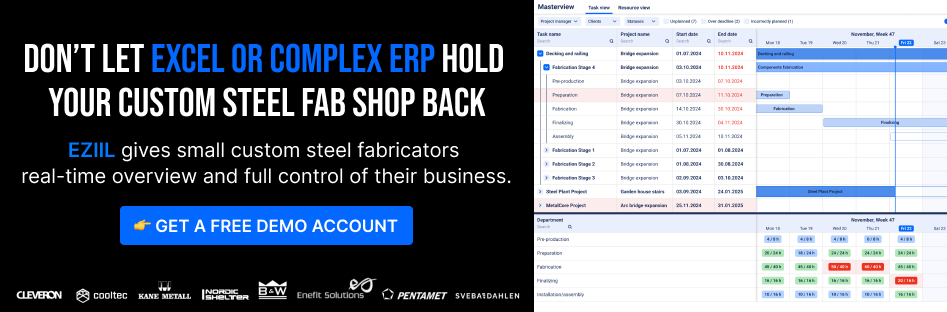

Why is EZIIL a Better Option Than an ERP or Excel for Small Custom Steel Fabricators?

EZIIL is intentionally designed as a lightweight, focused solution. Essentially, it’s a Manufacturing Execution System (MES) with all the necessary add-ons tailored to the needs of small- to mid-sized (10-50 people) custom metal fab shops.

It focuses on the core pain points (project planning, scheduling, shop-floor tracking, basic inventory and BOM management, etc.) without burdening you with extraneous modules.

More importantly, EZIIL’s approach to implementation is the opposite of a full-blown ERP rollout. You can start with just the pieces you need and add more when you’re ready.

“We avoided a huge ERP and went with EZIIL – and thank goodness. It has exactly what we need and nothing we don’t, which means we actually use it every day.”

For example, many shops begin with EZIIL’s Planning, Scheduling and Execution module (EZIIL Starter) to get immediate gains in visibility and coordination.

Other features like BOM, inventory tracking, purchasing management, or detailed cost analytics can be turned on later, or integrated with your existing solutions, as your processes mature.

This modular, phased adoption means you don’t have to overhaul everything at once, avoiding the operational paralysis that a giant ERP implementation can cause.

EZIIL’s simplicity doesn’t mean it’s not powerful. It just means it’s easily usable for every department. The interface is modern and intuitive, and EZIIL’s team provides hands-on support and training so that even non-technical staff can get comfortable quickly.

UPFAB, a small custom steel fabrication shop that recently implemented EZIIL, noted that even their less tech-savvy employees were able to start using the drag-and-drop scheduler within a day or two, whereas their previous ERP software (which they replaced with EZIIL) remained a mystery to many on the shop floor.

There’s no need for a full-time IT person to maintain EZIIL, and since it’s cloud-based, you don’t worry about servers or updates.

In terms of cost, EZIIL’s subscription model means far lower upfront investment than a traditional ERP, and you’re essentially paying in proportion to the value you’re using.

Many small shops find that EZIIL pays for itself quickly. For instance, just avoiding one late penalty or one botched project can justify a few months of subscription fee.

The key point is that EZIIL is designed specifically for small custom steel fabricators. It delivers the functionality that matters without the bloat, so you and your team aren’t overwhelmed. EZIIL proves you don’t have to choose between Excel (too little system) and a giant ERP (too much system). There is a “just right” solution in the middle!

A Need for Simple, Scalable Digital Adoption

For many small custom steel fabricators, the idea of digitalizing their operation is appealing in theory but daunting in practice. They know that sticking to paper and spreadsheets is unsustainable long-term, yet every software demo of a big system looks complicated, expensive, and risky.

What small custom steel fabrication shops truly need is a simple starting point, a solution they can adopt quickly to get some wins on the board immediately and then scale up as their needs grow and their team becomes more tech-savvy.

In other words, they need a gateway to digital transformation that won’t scare their people or break the bank.

We’ve heard executives say things like, “We want to modernize, but we can’t afford a 12-month implementation or a steep learning curve for our crew. If it’s not simple, it won’t get used.”

The importance of this scalability with simplicity cannot be overstated: a tool that works for a five-person shop should still work for a 50-person shop after growth, and the transition should feel natural, not like a complete reinvention.

How EZIIL Makes Adoption and Onboarding Fast and Simple for custom Steel Fabricators?

EZIIL was specifically built with this “start simple, then scale” philosophy in mind. It offers what we call a “layered adoption” approach.

Initially, you can digitize just one aspect of your operations. For example, scheduling and task management, and get your team comfortable with that.

EZIIL’s interface is user-friendly (a modern app, as opposed to a clunky ERP screen), and

EZIIL also has a dedicated onboarding team, that provides training and support so your people aren’t left struggling. Because each department only has to engage with the parts of EZIIL relevant to them, you can bring everyone on board at a manageable pace.

For example, in Week 1 EZIIL’s onboarding team helps you import everything from your previous tool or Excel sheets and set up the projects and schedule. In Week 2 the shop floor starts clocking in tasks on tablets, and by Week 3 you’re looking at your first auto-generated progress reports. This incremental success builds confidence.

How EZIIL Scales with Your Team and Growing Needs?

When you’re ready to expand, EZIIL scales with you. Need more advanced material management or integration with your accounting system? EZIIL has add-on modules for Bill of Materials (BOM) management, inventory tracking, and it can connect to tools like QuickBooks.

As your shop grows from 20 people to 60, you don’t outgrow EZIIL. The software helps facilitate that growth by keeping operations efficient and employees less stressed.

This scalable adoption means low risk and high flexibility. It’s the polar opposite of being locked into a huge ERP/MRP system that you must adapt to, instead, EZIIL adapts to you.

Majority of EZIIL customers have reported that this scalable and layered approach significantly reduced the fear among staff, even the old-school foremen who were wary of “software” eventually saw that EZIIL made their lives easier, and they embraced it.

By providing an easy gateway from pen-and-paper or Excel to digitalization and a clear path to scale up, EZIIL ensures that small custom steel fabricators’ first step into Industry 4.0 is a positive one, and that it won’t be their last step.

No Real-Time Project Visibility

When using spreadsheets and whiteboards, project status is never truly real-time. By the time you’ve manually updated a production schedule or collected progress info from the shop floor, that data is already stale.

Small shops often rely on periodic status meetings or phone calls to figure out what’s going on – a process one custom steel fabricator described as “running the shop by gut feel and yesterday’s information.”

In fact, an Excel-based schedule is only as accurate as the moment it’s printed or saved, it may be days out of date by the time management reviews it.

This lack of live visibility creates constant blind spots. Managers can’t see which jobs are on track or which are delayed right now, so they end up reacting to surprises (late parts, missed deadlines) after it’s too late. Employees on the shop floor, meanwhile, get frustrated when they’re asked about progress, because they often have to stop work to provide updates that weren’t being tracked centrally.

Overall, without real-time data, the whole operation runs in a kind of hindsight mode.

How EZIIL Solves the Lack of Real-Time Visibility?

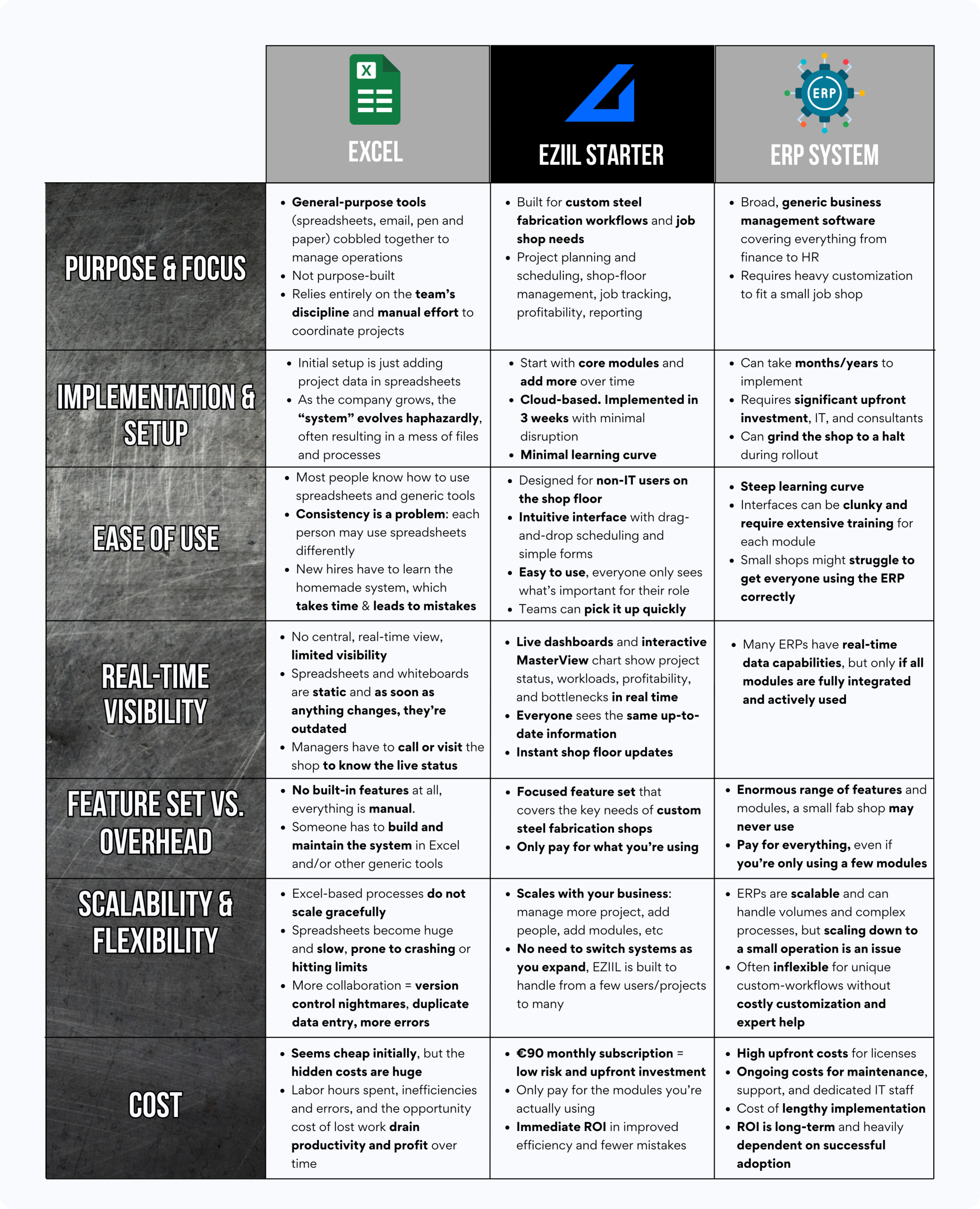

Eziil puts an end to these visibility issues by providing a real-time, bird’s-eye view of all projects in progress. The platform’s MasterView is essentially a live, interactive Gantt chart of your shop’s workload, updated instantly as tasks are started, paused, or completed.

Everyone, from project managers in the office to supervisors and welders on the shop floor, can see the same up-to-the-minute picture of production. Delays or bottlenecks become immediately apparent, not discovered a week later.

“With EZIIL’s MasterView we can finally see the next three months of work,” said one project manager, noting that for the first time they know exactly how full the shop is at any given moment.

This allowed them to make better decisions, for example, they started accepting jobs they would have previously declined (because now they can identify free capacity in the schedule), and conversely, they price rush orders higher if the schedule is tight (since it’s clear when the shop is at peak load).

EZIIL’s MasterView provides a real-time, color-coded timeline of all projects and tasks. Instead of relying on weekly meetings and gut feel, managers get instant visibility into each job’s status and upcoming workload. In this example MasterView screenshot, each bar represents a project phase, and the colors indicate progress, making it easy to spot which tasks are on track and which might need attention.

Everyone knows the score without sending a single email. A quick glance at the dashboard shows which jobs are in production, which department is working on them, and what percentage of each task is complete. Right now, not last week.

Real-time alerts will notify you of key milestones, so there are no more “surprise” deadlines. This level of live insight fundamentally changes how a small steel shop is run: instead of constantly reacting to problems after they occur, the team can anticipate issues and adjust proactively.

As a testament to that, we have had multiple fabrication CEO’s report back to us that after implementing EZIIL, they even canceled their standing production status meetings, because “everybody already had the information to make better decisions” by simply looking at EZIIL’s real-time overview. Their shops moved from chasing down updates to actively and efficiently managing production with data.

Scheduling Chaos and Resource Conflicts

Without an integrated scheduling system, many custom fab shops live in a state of scheduling chaos. Workloads aren’t leveled properly, and resource conflicts abound. We’ve heard from many customers, who transitioned to EZIIL from spreadsheets, that previously, they often ended up with “feast-or-famine” weeks. Five projects might have all coincidentally been due the same week, followed by a lull.

Because there was no global view of the schedule, project managers unknowingly over-committed the shop’s capacity. The inevitable result was lots of last-minute juggling, calling in favors or subcontractors at premium rates to meet deadlines, or delaying lower-priority jobs (and disappointing those customers).

In the case above, when an important material delivery was late, the team had to make urgent calls to contractors to keep the project on track, even eating back-charges for idle field crews. All because the schedule was packed too tightly.

This kind of ad-hoc scheduling also means people step on each other’s toes, as two jobs might need the same machine on the same day, or a critical welder gets double-booked, simply because there was no system to flag resource conflicts. Planners, using Excel, often admit that a single rush order or a machine breakdown would throw their Excel schedule into disarray, requiring hours of manual rescheduling and frantic phone calls to notify everyone involved.

How EZIIL Solves Scheduling Chaos and Resource Planning?

EZIIL brings order to scheduling chaos with visual, drag-and-drop scheduling and smart resource allocation features built for small custom steel job shops. Every project is broken into stages with assigned departments or work centers, all visible on a unified timeline.

Workloads can be balanced at a glance. If one week is overloaded, you’ll see it immediately and can adjust deadlines or shift some tasks to another week with a simple drag of the timeline bar. The software automatically highlights potential resource conflicts or overbookings as well, so you can’t accidentally schedule two different jobs for the same worker at the same time.

Instead of discovering conflicts on the day-of (when it’s too late), EZIIL users detect them in advance during planning. The platform even offers auto-scheduling suggestions based on your capacity. EZIIL can intelligently slot in projects according to resource availability, taking into account the sequence of operations (for example, you can’t start assembly until cutting and welding are complete).

The impact is dramatic: small steel fabrication shops that implement EZIIL report much smoother schedules and far fewer fire drills to rearrange work. “We can commit to delivery dates with confidence and avoid overloads now,” as one fabricator noted after moving their production management to EZIIL.

If a machine goes down or a customer requests a change, adjusting the schedule is fast and transparent. You simply drag the task to a new slot, and everyone up and down the line is automatically notified of the new plan. No more scribbling changes on a whiteboard and hoping everyone sees it.

By replacing guesswork with realistic, data-based scheduling, EZIIL helps small shops optimize their throughput without burning out their team. The software essentially enforces best practices (like not overloading any single work center, and maintaining some buffer for the unexpected), which reduces the chronic overtime and last-minute outsourcing that plague shops running on improvised scheduling. In short, EZIIL turns scheduling from a daily crisis into a manageable, predictable process.

Inaccurate Quoting and Job Costing

Quoting custom fabrication work is part art, part science, and without the right data, many small custom steel shops end up winning work that turns unprofitable or losing bids they could have handled.

A common pain point is that, using only spreadsheets and intuition, custom steel fabricators lack visibility into their true capacity and historical performance, which leads to inaccurate quotes. Project managers might quote low (cutting margins razor-thin) to win jobs during slow periods, only to find later that the shop was unknowingly fuller than they thought, causing schedule conflicts and overtime that erode any profit. On the other hand, they might quote too conservatively (high prices or long lead times) for fear of overloading the shop, and then end up with idle gaps in the schedule that mean lost revenue.

In short, opaque forecasting is a real issue: “Pricing was conservative for fear of gaps, or too low when the shop was full, eroding margin,” as one custom fab shop owner described their pre-EZIIL approach. Additionally, without a system tracking actual labor hours and costs on jobs, it was hard to know afterward whether a project really met its target margin. Feedback loops were weak, so the estimating process never improved much and costly mistakes repeated.

How EZIIL Ensures Accurate Quoting and Job Costing?

EZIIL tackles this problem head-on by providing accurate, data-driven quoting and job costing tools. First, because EZIIL gives real-time insight into your current and future capacity (as described above), estimators can see what the shop’s load will be when a potential new job would hit. This means you can confidently add an appropriate time or cost buffer for a rush job if the schedule is nearly full, or be more aggressive on price when you know you have slack capacity available.

In practice, EZIIL users have found this dramatically improves quote accuracy and profitability. For example, one custom metal fabricator reported that after using EZIIL’s scheduling visibility, they started charging a premium for tight-deadline projects (because they could quantify the impact on their schedule) and saw a higher win rate on the jobs that were a good fit. In fact, their average quoted project value increased by about 15% for fast-turnaround work, meaning they stopped leaving money on the table for urgent jobs. At the same time, they avoided taking on work during periods when the shop truly couldn’t handle it, preventing those nightmare clashes that used to force expensive overtime or subcontracting.

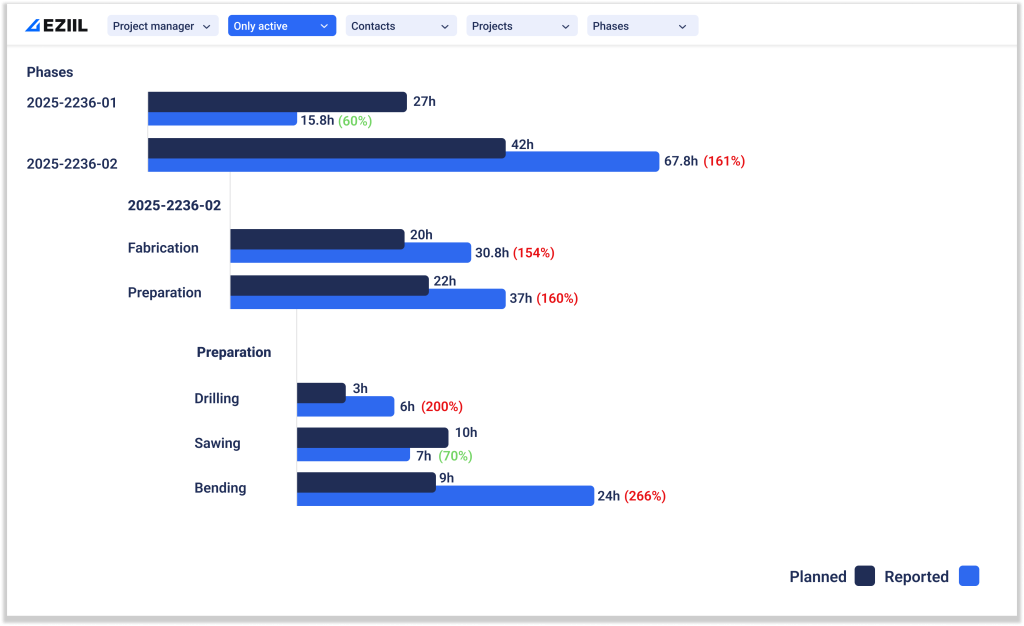

Eziil also brings the science into quoting by letting you compare planned vs. actual performance on every job. The software tracks hours logged and other costs as the project progresses, and then generates profitability reports at completion.

This closes the loop with your estimating process. You can pinpoint if, say, you under-estimated welding hours on a certain type of job, and adjust your quote assumptions next time.

Over time, EZIIL helps shops build a database of actual production data to refine quotes and avoid the common pitfalls of guesswork. It’s like having an automatic job-costing auditor: you’ll know exactly where you made or lost money on each project. And because all this data is centralized, you can filter it by client, type of work, etc., to find your most profitable project types (and which kinds to quote more carefully).

To sum it up, EZIIL gives small custom steel fabricators the kind of analytics that only big companies with ERP systems used to have, but in a far more approachable and budget-friendly way. The result is better quotes, better margins, and no more unpleasant surprises when the job is done.

No Centralized Place for Project Information

Do you know the frustration of hunting through email threads to find a client’s approval on a design change? Or digging through a network drive for the latest revision of a fabrication drawing, unsure if it’s actually the final version?

Small shops tend to suffer from having no single, centralized repository for project information. Instead, vital data is spread across emails, personal folders, paper files, and people’s brains. This lack of a centralized hub means that employees waste time searching for information (or worse, they proceed with outdated information). As the engineering lead at VMT Steelwork admitted, “All our BOMs were in separate Excel files on a shared drive – a spreadsheet for every project stage – and production data was scattered in different sources. It left far too much room for interpretation by our engineers and purchase team, and things slipped through the cracks.”

In a custom steel fabrication environment, where every project can have unique specs and changes, not having a single place to see all documents, notes, and status is more than an inconvenience. It can lead to serious mistakes like using the wrong material grade, missing an important customer requirement, or ordering components late because someone didn’t see the email.

How EZIIL Centralizes All Project Info into One Platform?

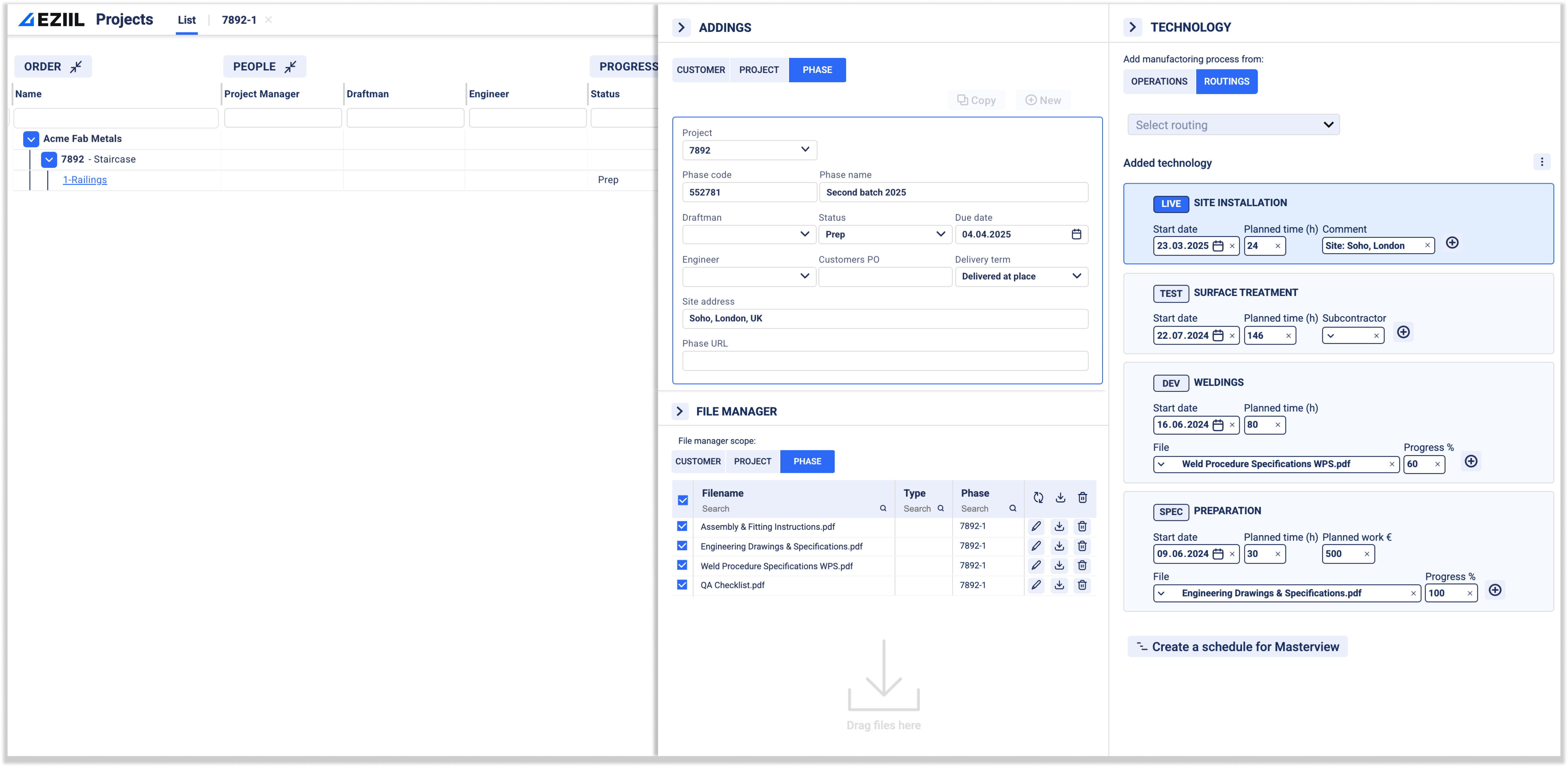

EZIIL provides a central project hub that brings all this information together. Every project in EZIIL has a dedicated space where you can store drawings, 3D models, client info, change orders, photos, certificates, you name it.

Instead of disparate file versions floating around, the team works off the files attached to the EZIIL project, ensuring everyone is accessing the latest documents. You can even group projects by client or category and quickly find what you need with filters.

There’s also role-based access control: for instance, your shop floor team can view the fabrication drawings and task instructions, but perhaps not the detailed quote breakdown, while the project manager can see everything. This means people have the info they need at their fingertips, without having to chase someone down for it.

By centralizing project data, EZIIL also makes onboarding new team members a lot easier. A new project manager or engineer can open up EZIIL and see all the context of a project (files, timeline, etc.) in one organized view, rather than piecing together tribal knowledge.

EZIIL is the “one-stop shop” for your shop’s information, dramatically reducing time wasted searching and eliminating errors caused by missing or wrong data. When every piece of project info lives in one system, you create a culture where people trust that if it’s not in EZIIL, it doesn’t exist, which drives consistency and accountability across the board.

Difficulties Managing Shop Floor Tasks

For many custom steel fabricators, getting clear work instructions to the shop floor and tracking their completion is a challenge. Without a digital system, shops resort to printed work orders, verbal instructions on the fly, or supervisors scribbling task lists on a whiteboard each morning.

These manual methods are not only time-consuming, but they also fall apart the moment something changes. Workers might start on a task based on yesterday’s plan, not knowing a new priority came up, or they might finish a task and then be idle waiting for the next assignment because the supervisor is busy putting out a fire elsewhere.

Managing shop floor tasks via paper and verbal communication often leads to confusion (“I thought Jim was handling that part?”), wasted time, and sometimes rework if tasks were misunderstood.

“On a week-long project, I used to spend 25% of my time just printing task lists and drawings and double-checking them. Now with EZIIL, it takes seconds – all the work orders and drawings are automatically organized in the right order. I can be sure every piece of information is handed over to production correctly.” – Rauno K., Technologist at VMT Steelwork.

How EZIIL Empowers Shop Floor Management?

A technologist at VMT Steelwork described how, before EZIIL, a huge portion of his week was spent simply printing out task lists and drawings and double-checking that everything was there for the crew: “On a week-long project, I spent about 25% of my time just printing out work tasks and drawings, assembling the documentation and checking that all information was included.” That was 10+ hours a week of pure admin overhead, and there was still the risk of a mistake. If anything was missing or mis-ordered in that paperwork, the shop might fabricate something incorrectly or come back asking questions that delay work.

He also added that after rolling out EZIIL, “everyone is now on the same page, eliminating delays and reducing rework” because the shop floor finally had clarity on their tasks and could give feedback instantly.

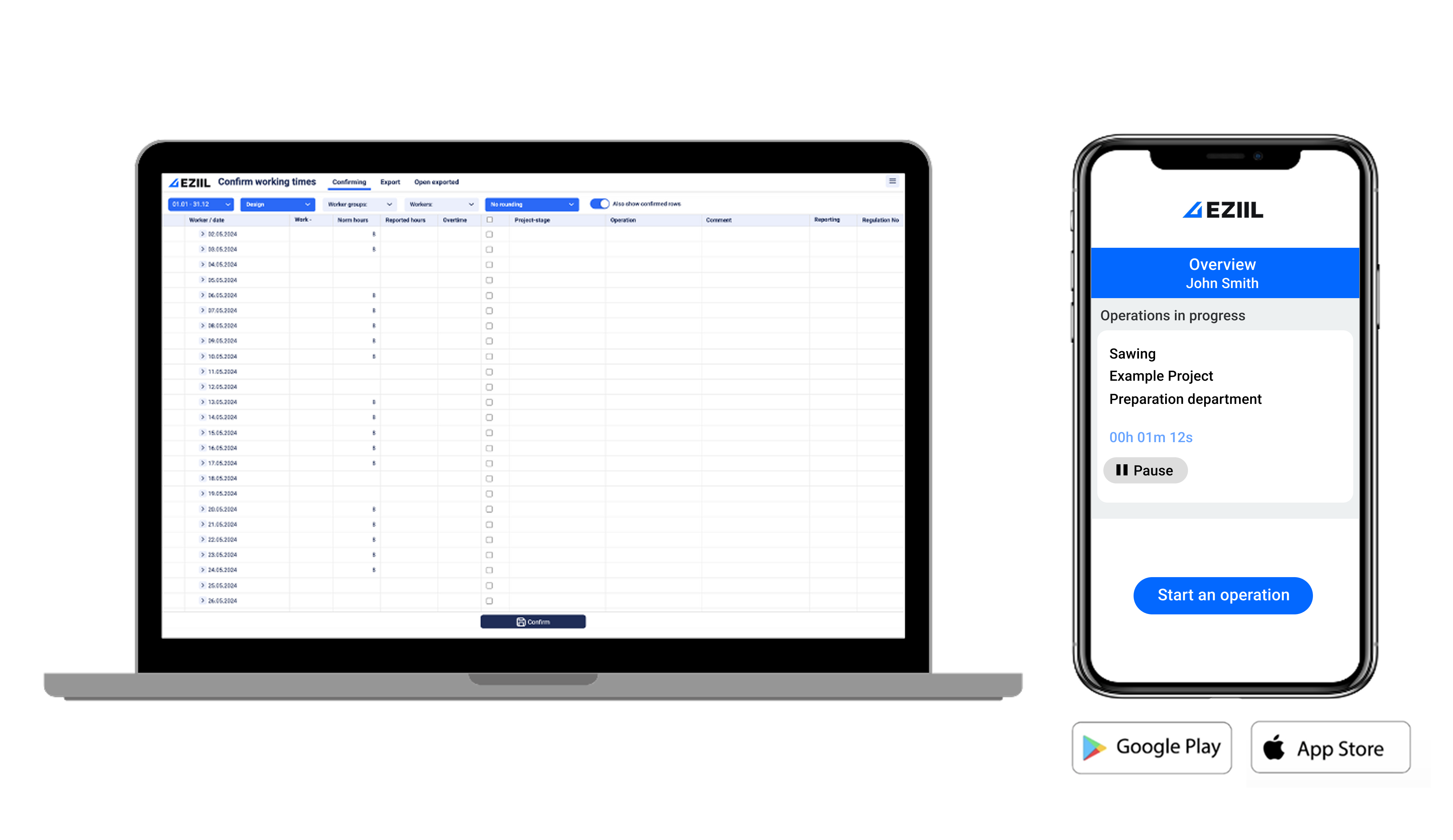

EZIIL transforms shop floor task management by digitizing and streamlining the entire workflow. You’ll simply assign tasks to workers or work centers with a few clicks, and those tasks appear on each team member’s dashboard (or even their smartphone, via EZIIL’s mobile interface) in real time. If the schedule shifts or priorities change, the updates are reflected immediately. No need to chase people down on the shop floor, everyone sees the new plan for the day on their screen. This ensures that every worker knows what to work on next at all times, eliminating downtime and confusion.

You’ll also be able to capture shop floor progress with minimal effort. Instead of filling out paper timecards or walking to the office to report completion, workers can simply start and stop tasks on a tablet or phone at their workstation. The time gets logged automatically, and the project’s progress percentage updates in EZIIL for managers to see.

This means no more nagging the floor for updates, as the system is continually updated as part of the workers’ normal routine.

An added benefit is consistency and completeness: EZIIL makes sure each task has all required info (drawings, specs, etc.) attached, so workers aren’t left guessing or hunting for details. The quote above from Rauno highlights how what used to take hours of prepping paperwork now takes seconds, because each work order in EZIIL includes all the necessary drawings and instructions, in the correct sequence.

The technologist’s role shifts from clerical work to oversight, and he can be confident that when he dispatches tasks through EZIIL, the shop floor has everything they need to execute correctly.

In summary, EZIIL brings structure and real-time communication to shop floor management: tasks are clearly defined, assigned, and tracked to completion without piles of paper or endless meetings. This not only saves time, but significantly reduces the chances of miscommunication that lead to scrap or rework.

Lack of Traceability and Compliance (e.g. EN 1090 Standards)

Traceability is increasingly important in steel fabrication. Whether it’s to comply with standards like EN 1090 for structural steel, or simply to maintain quality assurance and accountability. Small custom steel fabricators often struggle with traceability when they rely on manual record-keeping. It’s difficult to track which worker welded a particular beam, which batch of material was used, or whether every inspection step was logged, when all you have are paper weld logs or scattered spreadsheets. During audits or certification processes, this can become a nightmare: quality managers end up sifting through stacks of paperwork and inconsistent files trying to piece together a traceability trail.

For example, VMT Steelwork had all the requisite certifications (EN 1090-1, ISO 3834, etc.), but admitted that most of their procedures were still on paper or in people’s heads, and in countless spreadsheets.

The process relied on individuals “knowing what to fill in” and following unwritten rules. Not surprisingly, things fell through the cracks. They found that if someone forgot to follow the procedure on one of the many Excel sheets, the overall traceability overview was lost. In other words, their compliance depended on human memory and diligence across multiple disjointed documents, a very risky proposition. Mistakes in traceability can have serious consequences, from failing an audit (and losing certifications) to being unable to pinpoint responsibility for a defect or issue in the field.

How EZIIL Gives small custom steel Fabricators Enterprise-Grade Traceability?

EZIIL is built to provide full traceability and support industry compliance requirements out of the box. In EZIIL, every project and operation carries a digital log of who did what, when, and with which materials, which is exactly the kind of record standards like EN 1090 demand.

For example, when a welder starts a welding task in EZIIL (using the shop floor reporting app), the system can automatically record that “John Smith started weld on Beam A at 10:32 on Oct 5”, and when he finishes, it logs the completion time.

All this data is linked to the project and can be easily exported or reviewed for compliance documentation. EZIIL essentially creates a living audit trail for each job, without extra effort from your team. This means that when an auditor asks, “Can you prove that all welding was done by a certified welder and that inspections were carried out?”, you can pull up EZIIL and instantly show the digital paper trail.

Additionally, EZIIL centralizes quality and compliance documents. You can attach material certificates, weld procedure specs, inspection checklists, and any other compliance-related files directly to the project. This keeps those documents from getting lost in an email folder or a binder on a shelf, they’re right there with the production data.

By having every step digitally logged and all documents in one system, EZIIL makes maintaining compliance much easier and less error-prone. In fact, many shops report that after adopting EZIIL, their customers and certifiers gained increased confidence in their process because traceability became transparent and reliable. And beyond formal standards compliance, this level of traceability is just good business practice: if there’s ever an issue with a part, you can quickly identify what happened (who made it, which batch of material, etc.) and address it.

Communication Breakdowns Between Office and Shop Floor

“Left hand doesn’t know what the right hand is doing”. That’s how many small fab shops describe the communication gap between the office and the shop floor.

When using disconnected systems, coordination relies on constant human communication, which often breaks down. The office might issue a schedule or priority list in a meeting, but by mid-week the realities on the shop floor have changed (machine downtime, rework needed, etc.), and the plan is out the window. Yet the office isn’t aware until much later.

For example, the shop floor might encounter a problem (e.g. a drawing error or material shortage) and inform one engineer via email or a hallway conversation, but that information doesn’t reach the project manager or scheduler promptly, causing decisions to be made on outdated assumptions. Misalignment between the front office and production leads to mistakes, delays, and finger-pointing.

A common example is the office promising a delivery date to a customer without knowing that the shop floor is backed up. Without visibility or quick communication, they only find out there’s a problem at the last minute, resulting in a panicked “why didn’t anyone tell us?!” scramble. One shop noted that previously “if sales needed a status update on a project, they had to physically go check on the production floor”, a clear sign of broken communication flows.

How EZIIL Streamlines Shop Floor Communication?

EZIIL bridges the communication gap by connecting all stakeholders on one platform. Because EZIIL is cloud-based and accessible from any device, project managers, engineers, and shop floor workers are all effectively looking at the same dashboard.

EZIIL keeps the office and shop floor in sync by design. When an update is made or a problem logged, everyone who needs to know can see it in EZIIL in real time. A long-time EZIIL user and a fabrication co-founder noted that EZIIL “is built for exactly what we do, allowing us to plan more effectively and streamline our workflow”, highlighting that after adoption, the office and production were finally working effectively in sync.

Additionally, EZIIL reduces the need for endless status meetings or ad-hoc calls. Since everyone can log in and see up-to-date project status, resource availability, and priorities. This not only saves time, but it also fosters a more proactive culture.

The shop floor feels more empowered because they have visibility into the bigger picture. They can see why a certain job is priority today, or how their work impacts the overall schedule.

In essence, EZIIL creates a shared language and platform for the whole company. Resulting in fewer misunderstandings, faster response to issues, and a unified team pulling in the same direction. Communication no longer depends on who remembers to tell whom, the system itself keeps everyone updated. Many EZIIL users cite this as one of the biggest intangible benefits, the “wall” between office and shop floor comes down, and with it goes a lot of the frustration and blame that typically arise from miscommunication.

Time Wasted on Reporting and Progress Tracking

If you ask the leadership of a small custom steel fabrication shop how much time they or their staff spend every week on manual reporting and status tracking, the answer is usually “too much.”

In the absence of an integrated system, somebody has to constantly compile information: project managers update spreadsheets or prepare weekly progress slides, foremen walk the floor to check which jobs are done, engineers manually enter time logs into Excel, and so on.

This is non-value-added time! Hours that could be spent improving the product or process, but instead are spent playing data secretary.

“Before EZIIL, we were inputting the same data again and again in different formats. A huge waste,” said the COO of VMT Steelwork. And despite all this effort, the reports were always somewhat stale or incomplete. There’s also the time spent double-checking and correcting mistakes in reports, which is inevitable when things are done by hand.

How EZIIL Improves Reporting and Progress Tracking?

EZIIL automates and streamlines reporting, virtually eliminating the manual busywork. Because Eziil captures data at the source and generates reports on demand, no human compiling required.

Need to know the status of all active projects? It’s a click away, with each project’s progress percentage and any at-risk tasks highlighted.

Want to see how actual hours are tracking against the estimate for a job? EZIIL is updating that in real time as well. Instead of managers spending half a day preparing a weekly production report, they can let EZIIL produce live dashboards or export a summary with the latest data.

This not only saves time, but it also improves accuracy, as the data is coming straight from the system that people are using to do the work, so it’s less prone to transcription errors or missed updates.

EZIIL users, on average, report huge time savings and productivity gains from this shift. For example, UPFab, a custom steel fabrication shop from Michigan, with 35 workers, had thousands of parts that used to be keyed manually into spreadsheets for project tracking. Now, those come in automatically from their CAD software straight into EZIIL. They estimated this cut hours of data entry per project, allowing their staff to concentrate on value-adding tasks like optimizing the fabrication process rather than clerical work.

The bottom line is time previously wasted on reporting is now time spent on production, and managers can trust what the system is telling them rather than piecing together notes.

To Sum it Up

Project management and execution in small custom steel fabrication shops doesn’t have to be a juggling act of spreadsheets, guesswork, and hope. The pain points that have frustrated custom steel fabricators for years – disconnected systems, lack of visibility, scheduling nightmares, quoting uncertainties, communication breakdowns, and more – don’t have to be the status quo. As we’ve seen, many forward-thinking custom steel fabricators have found a better path forward by choosing EZIIL. They’ve traded in the chaos of Excel and the overkill of big ERPs for a purpose-built solution to run a custom fab shop efficiently and profitably.

By addressing the everyday challenges (from ensuring the whole team works on one platform to keeping projects on schedule and within budget), EZIIL empowers small fabrication companies to deliver projects on time, every time with confidence.

Don’t let Excel or an unwieldy ERP hold your custom fabrication business back. Digital transformation with EZIIL is a manageable, affordable step that can unlock significant efficiency and clarity in your operations. Embrace a tool built for custom steel fabrication! Your shop floor will thank you, your customers will notice the difference, and you’ll wonder how you ever managed without it.

See EZIIL in action for yourself

Sign up to our free interactive demo account and take a tour in EZIIL!

No need to import any of your data or fill in project information. The demo account is already pre-filled with steel project data, so that you can browse the software using a real scenario.

If you have any questions or would like to discuss your specific use case, you can book a free demo with EZIIL. We’ll answer any questions and use your shop’s typical workflow as an example of how things could be improved.