Capacity Planning

What is Capacity Planning?

Capacity Planning is the process of determining the production capacity needed to meet the changing demand for products.

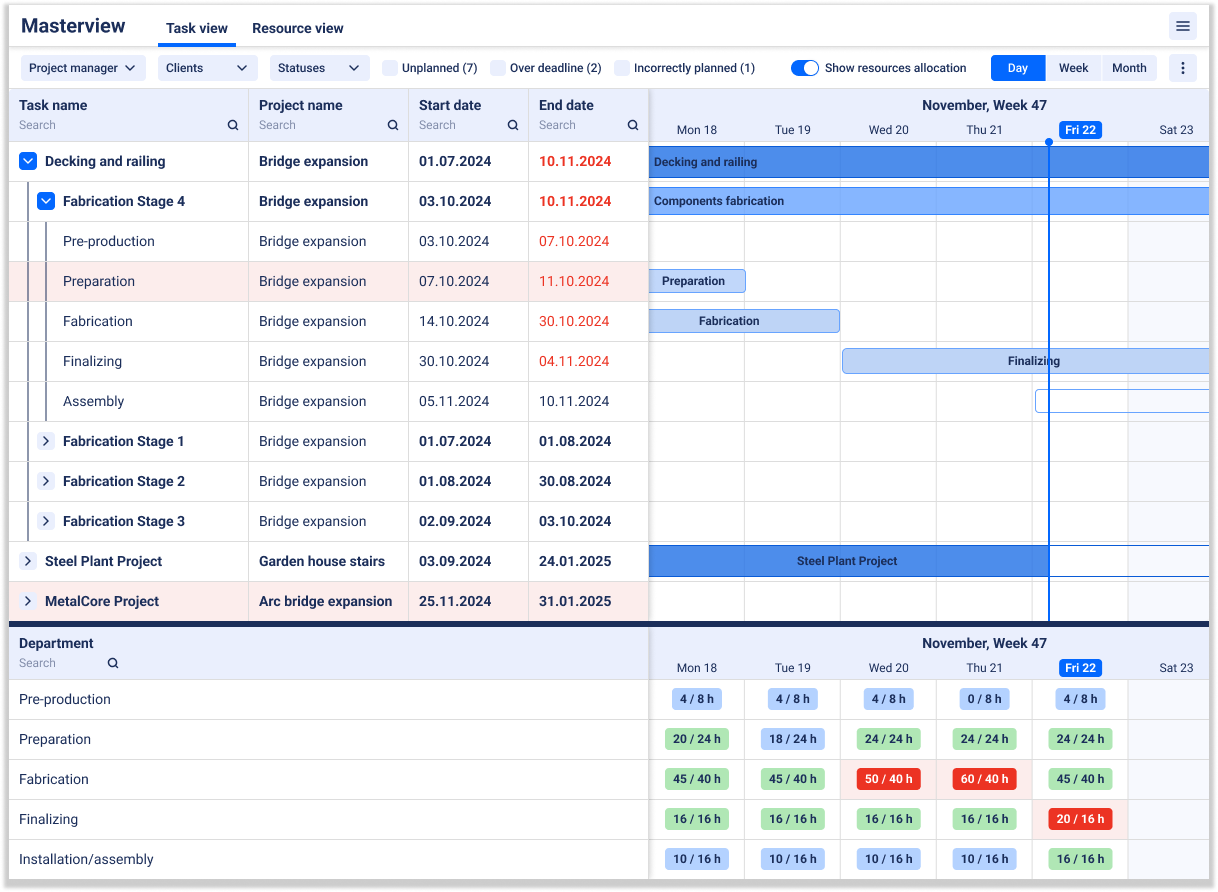

In practice, it means figuring out if your shop’s machines and labor hours are sufficient for the workload, and if not, how to adjust (overtime? subcontract? invest in new equipment?).

For a small steel fabricator, capacity planning usually involves analyzing how many labor hours and machine hours are required for all open jobs versus available hours in a week. It draws from the routing and scheduling data. For example to see if upcoming projects will overload the welding bays or paint booth and if management must plan to add a shift or stagger schedules.

The goal of effective Capacity Planning is to minimize the mismatch between capacity and demand: underutilization wastes resources, while overutilization causes delays and quality issues.

By forecasting load (using a dedicated steel fabrication system like EZIIL), small shops can proactively adjust capacity through hiring, outsourcing, or shift changes.