Lean Manufacturing

What is Lean Manufacturing?

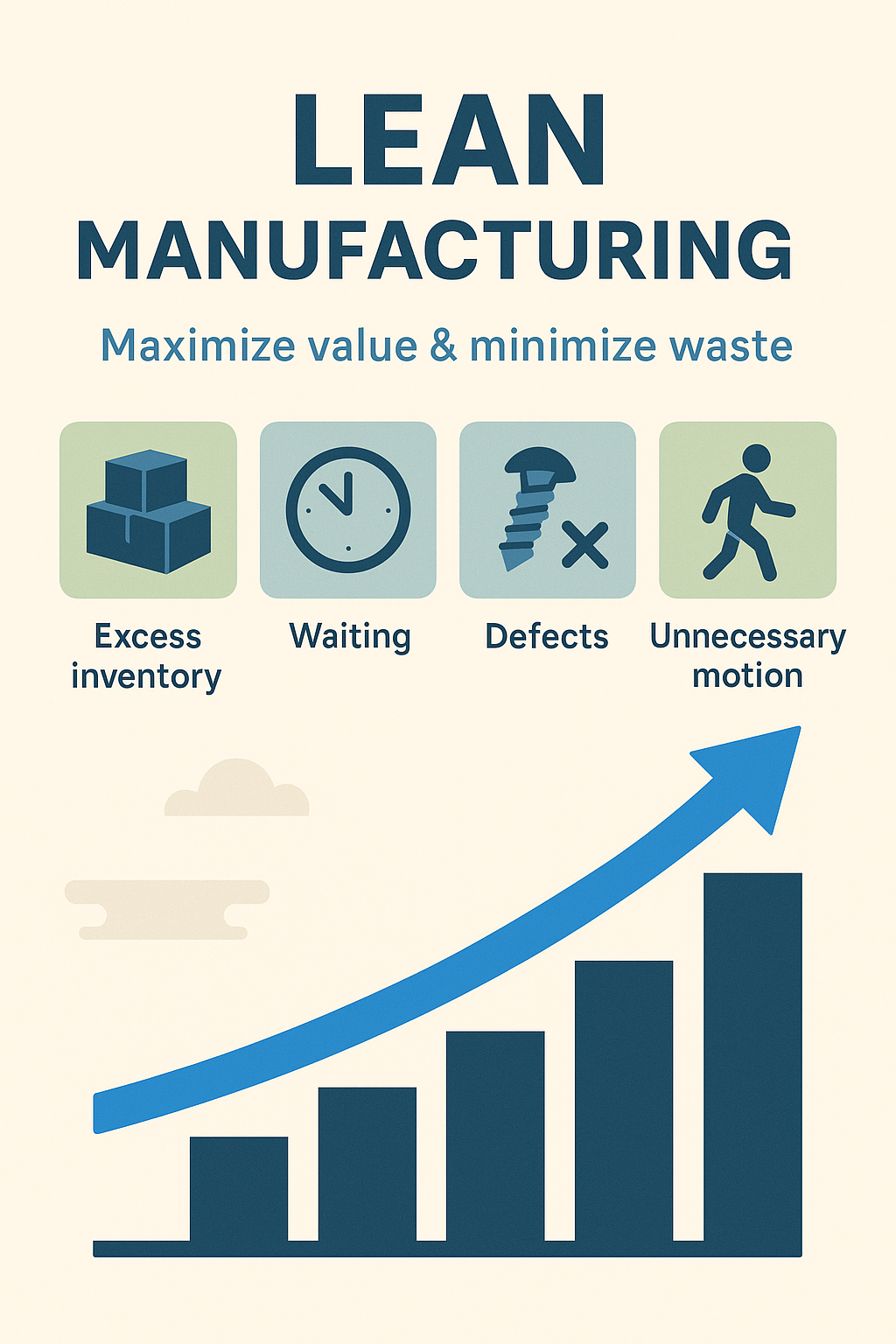

Lean Manufacturing is a production philosophy focused on maximizing value and minimizing waste in processes.

Lean principles (originating from the Toyota Production System) encourage small shops to continuously identify and eliminate non-value-adding activities, such as excess inventory, waiting time, defective work, unnecessary motion, etc.

For a custom steel fabricator, lean might mean organizing the shop floor for smoother flow (so material isn’t waiting long between cutting and welding), implementing 5S workplace organization to reduce time wasted searching for tools, or using pull systems (like Kanban cards) to avoid overproduction.

The core idea is that every step that doesn’t add value to the customer (who cares about a quality steel structure delivered on time) is a form of waste (called muda in Lean terminology) that should be relentlessly reduced.

Lean is contextually very useful for small fabrication shops. Even without large-scale automation, simple lean practices like standardizing work, cross-training employees, and quick changeovers can significantly improve throughput and margins.