Machine shop scheduling

What is machine shop scheduling in steel fabrication?

Machine shop scheduling is the planning and sequencing of jobs across machines where each job has a defined route and constraints. Many jobs require multiple operations in a specific order, and each machine can usually process one operation at a time.

In a steel fabrication shop, machine shop scheduling often applies to:

CNC drilling, tapping, milling

beam line operations

saw + drill + notch sequences

plate processing steps

any specialized station that becomes a constraint

Why machine shop scheduling matters in steel fabrication?

Machining steps often become silent schedule killers because they sit between “easy” departments:

-

parts get cut, then wait for drilling

-

assemblies wait for tapped holes

-

finishing waits because machining rework is required

-

shipping slips because one machined component is missing

Machine shop scheduling helps you:

-

protect due dates by prioritizing the right operations

-

reduce setup loss by smarter sequencing

-

avoid starving downstream steps (fit-up, welding, assembly)

-

decide when to subcontract overflow instead of drowning the schedule

Best practices for machine shop scheduling that actually work on a shop floor

1) Identify the constraint machine

In many shops it’s a CNC, beam line, or specialty station. Schedule that machine first. Everything else should support it.

2) Include setup time, not just run time

Setup dominates in HMLV. If you ignore it, your plan will be fantasy.

Track:

tool changes

fixture changes

program changes

first-piece verification

Then sequence to reduce disruptive changeovers.

3) Group work intelligently

Batch by what reduces pain:

same material thickness

similar tooling/fixtures

similar programs

But do not batch so aggressively that urgent jobs miss their due dates. Balance flow with efficiency.

4) Maintain a ready queue

Keep a small buffer of “fully ready” machine work:

drawings/programs ready

material staged

priority confirmed

This prevents downtime that shows up as “we were waiting on info.”

5) Use routing clarity

For jobs that bounce across saw → CNC → deburr → weld, routing confusion creates rework and lost parts. Make sure the next step is always explicit and parts are traceable.

6) Replan daily with real progress

Machine schedules change quickly. A short daily update is more valuable than a perfect plan made once a week.

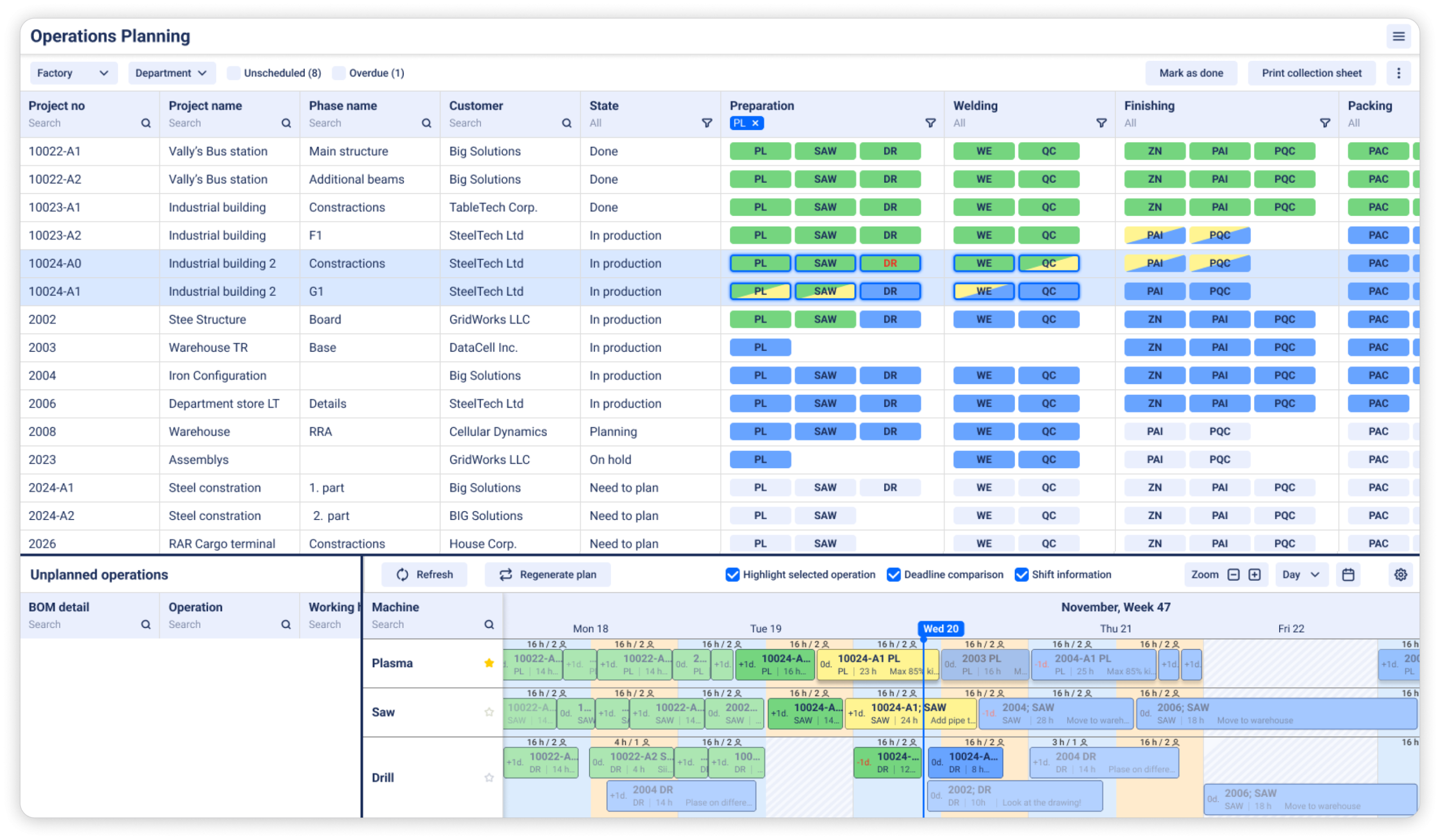

How EZIIL supports machine shop scheduling

EZIIL helps connect machining steps to the broader fabrication plan so machining doesn’t become a black box:

break jobs into phases/operations with clear owners and due dates (so machining work is not “floating”)

keep priority and deadline context attached to each job, so machine decisions align with ship dates

capture plan vs actual so you learn where machining time is underestimated, which improves quoting and future scheduling

store programs, setup notes, and work instructions with the job so the machine shop is not hunting through emails and folders

A practical example: if your CNC is the constraint, EZIIL helps you see what jobs are feeding assembly next, then schedule CNC work to protect those downstream milestones instead of running “whatever is easiest.”