Order cycle time

What is order cycle time in steel fabrication?

Order cycle time is the total elapsed time from when a customer order is accepted to when the order is shipped or delivered. In other words, it captures the customer’s waiting experience, including admin time, procurement waits, queue time on the floor, and shipping.

This aligns closely with lead time concepts (order to receipt), versus cycle time, which often focuses on active work time only.

In steel fabrication, you should define it clearly because shops often disagree on what “start” and “finish” mean. Choose one definition and stick to it for trend tracking.

Common definitions:

Start: PO accepted, deposit received, or drawings approved

Finish: shipped, ready for pickup, or delivered/installed

For most shops, the best default is:

Start = PO accepted (or job approved to proceed)

Finish = shipped/ready for pickup

Why order cycle time matters in steel fabrication?

Order cycle time is one of the few metrics that tells you whether your shop is becoming easier to buy from. Customers do not care that welding “only took two days” if the job spent three weeks waiting on material, approvals, and shop queues.

Tracking order cycle time helps you:

Quote more accurately (lead times based on real performance, not best-case thinking)

Improve cash flow (shorter cycle = faster invoicing and fewer WIP dollars stuck on the floor)

Reduce expediting (rush costs are usually symptoms of poor flow)

Improve customer communication (you can explain what stage the job is in and what’s blocking it)

In HMLV/MTO work, cycle time is often dominated by waiting. That’s why breaking the total into phases matters.

Best practices for measuring order cycle time in a job shop

1) Write down the definition and keep it consistent

You cannot improve what you keep redefining. Pick the start/end points and document them.

2) Track the “phase time,” not just the total

A shop-friendly breakdown is:

engineering/drawings

procurement/material readiness

cutting

forming

fit-up

welding

finishing

assembly

QC/pack

shipping

Once you see where days pile up, improvement gets obvious.

3) Use distributions, not just averages

Averages hide ugly reality. Track:

median (typical performance)

80th/90th percentile (what happens in bad weeks)

This is what protects your quote promises.

4) Capture delay reasons as a short list

Keep it simple: waiting on material, drawing changes, rework, subcontract lead time, capacity overload, customer change request. A few consistent categories beats a messy spreadsheet of 50.

5) Reduce WIP on purpose

Most shops try to lower cycle time by starting earlier or starting more. That usually increases WIP and makes everything slower. Instead:

gate release by readiness (material + drawings + approvals)

limit WIP per department

protect the bottleneck with ready work

6) Build a weekly rhythm

A 30-45 minute weekly review (plus a quick daily check-in) is enough:

Which jobs are trending late?

What must move this week to protect ship dates?

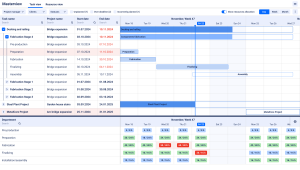

How EZIIL helps reduce order cycle time

Order cycle time drops when you can see work clearly, keep handoffs tight, and stop losing time to ambiguity.

EZIIL supports that by:

giving one shared view of active jobs, deadlines, and ownership so priorities stop living in someone’s head

making blockers visible quickly through statuses and comments, so waiting time is exposed, not hidden

enabling plan vs actual tracking so you can identify where estimates or workflows are consistently wrong (and fix quoting or process steps)