Throughput Dollar-Days/Inventory Dollar-Days (TDD/IDD)

What is Throughput Dollar-Days/Inventory Dollar-Days (TDD/IDD) in steel fabrication?

TDD (Throughput Dollar-Days) and IDD (Inventory Dollar-Days) are Theory of Constraints (TOC) style metrics that combine money × time to show the real pain of lateness and inventory.

Instead of treating every late job the same, they weight impact by dollars.

IDD measures how much cash is tied up in inventory and for how long. It’s commonly described as the value (or cost) of inventory × days it’s been sitting.

TDD measures how much throughput value is “late” and for how long. It’s a way to quantify late deliveries weighted by their economic impact.

Why Throughput Dollar-Days/Inventory Dollar-Days matter for custom steel fabricators

Custom fabrication is basically a constant tradeoff between:

releasing work early “just in case” (which increases WIP + IDD)

keeping WIP under control (which reduces IDD but demands better planning)

TDD/IDD help you answer two questions quickly:

Which late job hurts us most right now? (TDD)

Where is our cash stuck aging on the floor or in the rack? (IDD)

How to use to use TDD and IDD in a steel shop

You can adapt the concept with shop-friendly inputs:

IDD for WIP aging

Assign a value (material cost, or “job value”) to each open job

Multiply by days since release to production

Sort descending: that’s your “aging money pile”

TDD for priority

Assign a value (contribution margin, or job price)

Multiply by days late vs committed ship date

Highest score gets attention first (not whoever shouts loudest)

Best practices for TDD and IDD

Set WIP limits (release work when there’s capacity, not when you feel nervous)

Kit materials before release to avoid half-started jobs aging on the floor

Use buffer-based urgency (what must move today to protect ship dates)

Review top 10 “aging jobs” weekly: remove blockers, fix routing mistakes, rebalance labor

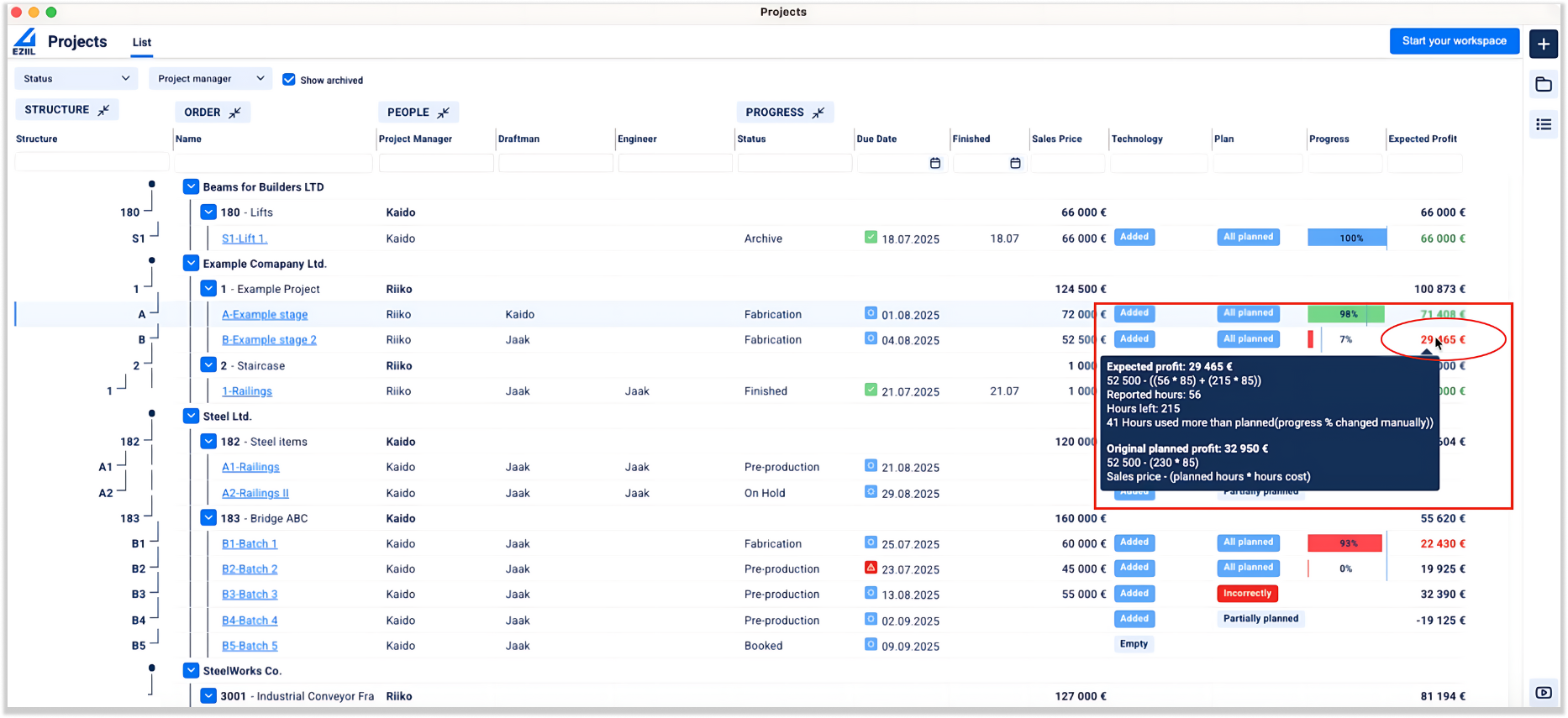

How EZIIL helps with TDD and IDD

If you’re using EZIIL’s steel fabrication software you can:

See all active projects and deadlines in one place (so urgency is shared, not tribal knowledge)

Assign and track work across departments, then spot where jobs are stuck before they become “surprise late”

Compare planned vs actual to catch early warning signals (a job burning hours fast usually becomes a TDD problem later)

Use real status updates to reduce the “inventory you forgot you had” problem