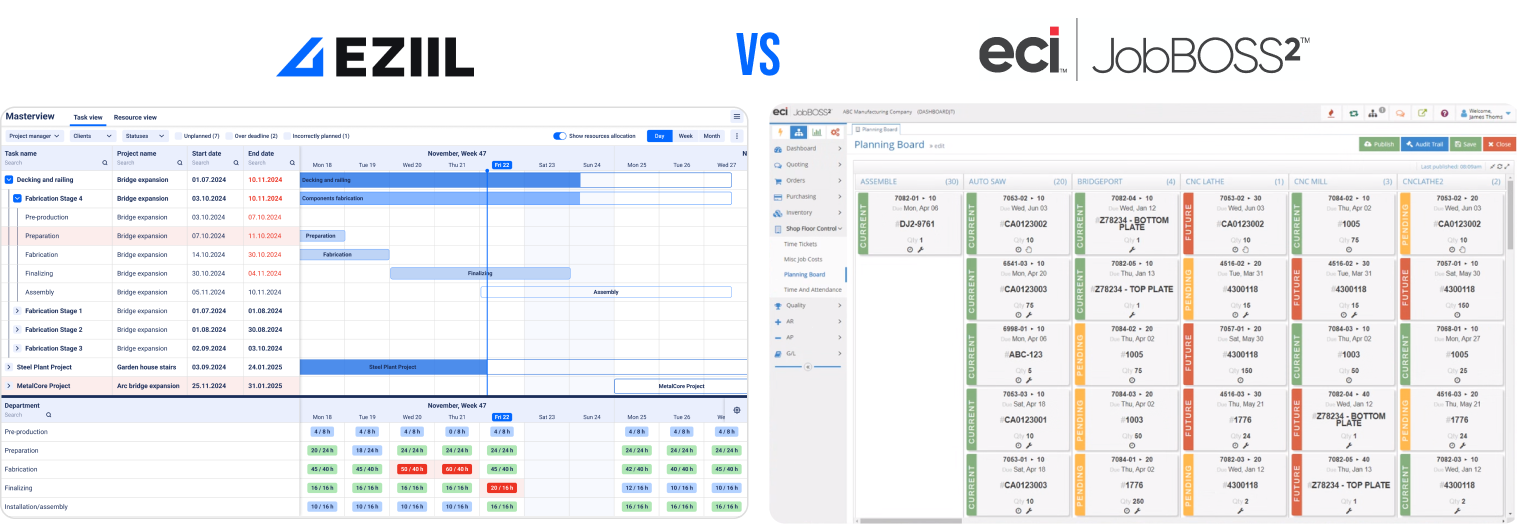

In this comparison we’re putting ECI JobBOSS 2 vs EZIIL side by side to see which software suits best for small custom steel fabricators who want a practical, shop-floor friendly system that fits how custom steel projects actually flows.

We’ll focus on what matters in your day to day: time to first live job, clarity of stage based scheduling across cutting, welding, painting, and install, real time visibility into job profitability while the work is still running, EN 1090 friendly traceability, and how easily the crew logs work on the floor. You will also see how each handles mixed drawing formats, QuickBooks workflows, and the true cost to adopt without an in-house IT team.

JobBOSS² vs EZIIL Starter at a glance: comparison table

| What matters to a small custom steel shop | EZIIL Starter | JobBOSS² | Why it’s important? |

|---|---|---|---|

| Deployment and focus | Cloud MES for project-based metal fabrication. Built to replace spreadsheets with lightweight adoption. | Cloud ERP for job shops. Broader manufacturing scope. | Cloud keeps IT overhead low and speeds roll-out for small teams. A steel-focused MES gives stage-based scheduling, traceability, and in-shift cost control without ERP bloat, so small teams get value fast. |

| Setup approach | Phased, modular adoption so you can start small and expand. Dedicated project manager to support smooth rollout and adoption. | Structured multi-phase implementation with a dedicated project manager. | A phased rollout shortens training and reduces risk of disruption, downtime and change fatigue on the floor. |

| Scheduling clarity for steel stages | Visual, drag-and-drop scheduler built for metal fabrication stages with capacity checks and bottleneck visibility. | Scheduling module manages work schedules and load, geared to general job-shop flows. | Stage-based visibility across cutting, welding, painting helps keep promises to GCs. |

| Shop-floor reporting | Lightweight mobile reporting and task queues for quick time and status logs. | Shop-floor data via JobBOSS² plus ECI MES integration when needed. | Adoption lives or dies on how easy it is for welders and fitters to use. |

| Real-time profitability while the job runs | Real-time planned vs actual profitability tracking at project or stage level to spot margin drift mid-job. | Estimated vs actual reporting available within ERP. Depth varies by setup. | Catching overruns early protects thin project margins. |

| Traceability and compliance | Logs who did what and when, suitable for EN 1090 workflows. | Traceability and quality controls supported in ERP stack. | Proves accountability, reduces rework risk, supports certifications. |

| Drawings and BOM intake | Works with PDFs and 2D drawings. BOM import options available. | BOM management available as standard ERP capability. | Many small shops rely on external detailers and mixed formats. |

| Accounting stance | Keep accounting in QuickBooks or similar accounting software, integrate or export as needed. | Built-in accounting available or sync to QuickBooks Desktop or Online. | Best-of-breed keeps finance stable while ops digitize. |

| Pricing model | Transparent monthly subscription entry point for small shops. Starting at €90/month (1-15 users). | Tiered, quote-based licensing with training and services. | Cash-flow friendly monthly subscriptions reduce adoption friction. |

| Best fit | 10–50 person custom steel fabricators who want fast wins without ERP bloat. | Broad job shops needing classic ERP breadth plus optional MES. | Picking the tool that matches your work style avoids costly workarounds. |

EZIIL Starter – Custom Steel Fabrication Management Software

EZIIL Starter is a lightweight cloud-based project management and Manufacturing Execution System (MES) for project-based metal fabrication that replaces spreadsheet chaos with one live system for planning, tracking, and shop-floor reporting. It gives you real-time dashboards, visual scheduling, and plan-versus-reality insights so you see delays and margin drift before they hit delivery dates.

Who is EZIIL Starter for

EZIIL Starter was specifically designed for small custom steel fabricators with 10–50 people who run stage-based jobs like cutting, welding, blasting, painting, and installs, and want to digitize the floor without taking on ERP bloat or a big IT project. Most teams adopt EZIIL Starter as their first step off Excel and whiteboards, keeping accounting in QuickBooks while operations move to a digital single source of truth.

EZIIL Starter: Key capabilities

- Real-time job profitability while the job runs. Set sales price at project or stage level and track expected vs actual profit from hours and labor rate, with clear signals telling you whether you’re on or off track.

- Visual scheduling with bottleneck alerts. Drag-and-drop stage timelines, capacity view, and color cues for fully planned, partially planned, or off-sequence tasks, plus deadline health.

- OTD visibility. Department-level on-time, late, and in-progress indicators drive accountability without extra data entry.

- EN 1090-friendly traceability. Log who did what and when on the shop floor, suitable for EX2/EX3 requirements and bigger, traceable contracts.

- Shop-floor mobile app for fast reporting. Workers see task queues, log hours on phones or tablets, and view drawings or QC images at the station.

- All project documents in one place. Store drawings, blueprints, and project docs, and build repeatable production routings so new projects are set up in minutes.

👉 Learn more about the latest feature updates in EZIIL Starter.

EZIIL Starter pricing and adoption

EZIIL has a transparent monthly subscription starting from €90 per month with tiers by user count, paid monthly or annually (you save 20% on annual deals). Shops commonly get to first live projects in a few weeks with a phased rollout and EZIIL-assisted setup.

EZIIL Starter Pros and cons for a Small steel fabbrication shop

Pros ✅

- Built for custom steel workflows, so stage-based scheduling and traceability work out of the box.

- Fast time to value with minimal IT overhead and a monthly subscription. You can scale and add modules as you grow and when you’re ready.

- Margin control while jobs are still running, not weeks later at invoicing.

- Easy shop-floor adoption through mobile logging and clear task queues.

Cons ❌

- Not a full ERP. Deep accounting, advanced purchasing, or complex inventory require adding modules from EZIIL Enterprise or keeping finance in QuickBooks.

- Best for project-based custom fabrication. High-volume, part-centric manufacturing might prefer a traditional job-shop ERP.

If your goal is to get out of spreadsheets, see your schedule and margins in real time, and meet EN 1090 requirements without overhauling finance, EZIIL Starter is purpose-built for that first, pragmatic leap.

JobBOSS – job-shop ERP for manufacturers

JobBOSS² is ECI’s ERP for small job shops and custom manufacturers. It’s offered primarily as a cloud product, with an on-prem option available. JobBOSS² ERP covers quoting, scheduling, inventory, purchasing, shipping, accounting, and reporting for broad job-shop workflows across many industries.

Who is JobBOSS² for

JobBOSS ERP suits manufacturers that want an all-in-one software to handle quoting, orders, scheduling, inventory, purchasing, shipping, and accounting in one system. It’s a specifically useful software for manufacturers who run repeat or part-centric work with routings and inventory-driven jobs.

JobBOSS²: Key capabilities

- Quoting and orders. Create estimates, convert to jobs, and manage work schedules and load.

- Job costing and reporting. Compare estimated vs actuals, track profitability and productivity.

- Scheduling. Finite scheduling and capacity views aimed at job shops; deeper shop-floor controls are available by integrating ECI’s MES.

- Inventory and purchasing. Real-time inventory tracking, forecasting, purchasing, and shipping docs.

- Accounting options. Use built-in accounting or sync with QuickBooks Desktop or Online.

- Data collection. Time and data capture within JobBOSS², with optional ECI MES to expand real-time shop-floor visibility.

JobBOSS² pricing and adoption

ECI does not publish list pricing. JobBOSS² is sold as a subscription with packages and minimum one user. Total cost varies by users, modules, and services. Implementations follow a formal multi-phase process led by an ECI project manager, which ECI frames as a significant ERP transition. Expect structured onboarding, training, and configuration before go-live.

JobBOSS² Pros and cons for a Small steel fabbrication shop

Pros ✅

- Breadth in one system: Quoting, scheduling, inventory, purchasing, accounting, and reporting under one ERP umbrella can simplify vendor management for shops that want everything in one place.

- Accounting flexibility: Choice of built-in accounting or QuickBooks sync fits different finance setups.

- Deployment choice: Cloud-first with an on-prem option for shops that need it.

Cons ❌

- Implementation weight: ERP-style rollout with multiple phases and training can be slower to first live job compared to lighter MES deployments.

- Scheduling fit: Several users on review sites and forums report friction with scheduling depth and ease, which may require extra configuration or complementary MES for the floor.

- Cost transparency: Pricing is quote-based and not published, so modeling total cost of ownership requires a sales process.

- Steel-specific workflows: JobBOSS² ERP system is built for broad job shops rather than project-stage steel flows. EN 1090-style traceability may be achievable via configuration and procedures rather than out-of-the-box steel workflows. Validate in discovery if EN 1090 is critical.

where EZIIL Starter and JobBOSS² differ for custom steel Fabrication

In a nutshell, if your work looks like classic job-shop manufacturing with repeat parts and you want ERP breadth, JobBOSS² is a good fit. If your pain is stage-based steel scheduling, quick shop-floor adoption, and live margin control while projects run, a focused MES like EZIIL typically reaches value faster with fewer workarounds.

Fit for project-based steel vs part-centric job shops

EZIIL Starter: Purpose-built for project-style metal fabrication. Optimized around stage-based flow and quick adoption for teams moving off Excel.

JobBOSS²: Broad job-shop ERP covering quote-to-cash for many industries. Strong for part-centric and repeat work with classic ERP breadth.

☝️ Why it matters: If your work breaks into stages like cutting, welding, blasting and paint, a fabrication-first MES reduces workarounds and speeds time to value.

Scheduling clarity for stages like cutting, welding, painting

EZIIL Starter: Visual drag-and-drop scheduler built for metal-fab stages, with OTD status and workload health at a glance.

JobBOSS²: Offers scheduling and whiteboard views; for deeper, automated shop-floor scheduling ECI positions an MES add-on.

☝️ Why it matters: Stage-level visibility makes it obvious where a job is sliding so you can re-sequence before deadlines slip.

Shop-floor usability and reporting speed

EZIIL Starter: Lightweight shop-floor app for fast time capture and task queues, with drawings and QC images available at stations.

JobBOSS²: Time and data collection is available inside ERP, with ECI MES for machine data and richer real-time visibility if needed. Some user threads call out reporting and UI friction that may require configuration.

☝️ Why it matters: Adoption rises when welders and fitters can log work in seconds and see what is next without hunting through screens.

Traceability and EN 1090 support

EZIIL Starter: Explicit support for EN 1090-style traceability with logs of who did what and when, suitable for EX2 and EX3.

JobBOSS²: Quality and ISO modules are available, but EN 1090 is not specifically mentioned in vendor resources. Validate requirements in discovery.

☝️ Why it matters: Traceability proof cuts rework risk and is often mandatory on structural packages.

Works without in-house detailers and mixed drawing formats

EZIIL Starter: Built to run with PDFs and 2D drawings on the floor. BOMs (add on module) and docs live centrally for easy access.

JobBOSS²: ERP BOMs are standard, with CAD BOM integration resources available.

☝️ Why it matters: Many small steel shops rely on external detailers. You need a system that tolerates mixed inputs, not only model-driven data.

Implementation risk, training needs and Technology overhead

EZIIL Starter: Phased rollout keeps accounting in QuickBooks (or other accounting software you’re using), starts with a live project, and expands as the crew is ready. Typical onboarding is a few weeks. Cloud delivery means no servers to maintain.

JobBOSS²: Formal structured ERP implementation with a dedicated project manager, training and configuration. Cloud or on-prem options.

☝️ Why it matters: Smaller teams have limited change bandwidth. A lighter footprint reduces downtime and training fatigue.

Total cost of ownership and ability to start small

EZIIL Starter: Monthly subscription model (starting from €90/month) with modular scope so you can start lean and add capabilities later.

JobBOSS²: Pricing is obtained via quote. JobBOSS provides packages and payment options, but public price sheets are not listed.

☝️ Why it matters: Transparent, start-small paths help small job shops de-risk the move off spreadsheets while keeping cash flow predictable.