If your shop runs make to order (MTO) work with lots of small, custom jobs, you know how easy it is for dates to drift when parts arrive late, drawings change, or material certs take time to trace.

Global steel demand has moved back to a growth path, which keeps pressure on delivery promises and margins.

With that pressure, increasingly more and more metal fabricators are juggling high-mix, low-volume (HMLV) schedules that need tighter links from engineering into the shop floor so the plan matches reality. At the same time, leaders still cite supply chain and workforce constraints as ongoing blockers, which makes predictable capacity and material control even more important.

For structural work sold in the EU and UK, EN 1090 adds another layer, since components must be CE marked and manufacturers need documented processes and traceability for audits.

This is exactly the gap EZIIL Enterprise, a purpose-built metal fabrication ERP software for MTO shops, will help close. Think live capacity planning, machine and operation scheduling, shop-floor reporting, purchasing and inventory, subcontractor returns, and certificate genealogy in one place. The reality is, that most generic ERPs are not built for custom metal fabricators in mind. So let’s take a look how EZIIL Enterprise works, how it differs from generic ERPs, how it caters to the exact needs of growing metal fabrication shops, and if it’s the right solution for your shop.

Why generic ERPs and DIY Excel-based systems fail metal fabricators?

Metal fabricators that run high-mix, low-volume and make-to-order work reach a point where spreadsheets and generic ERP can no longer keep the plan aligned with what is really happening on the floor. A research on HMLV operations shows that delivery performance depends on daily scheduling and material allocation decisions that change often, which is where simple production management tools start to bend. Additionally, the recent MIT study on HMLV job shops underlines how fast variability in routings and concurrent jobs complicates scheduling beyond manual methods. As mentioned earlier, supply chain and labor constraints have also persisted, which reduces slack and makes predictable capacity and material control more important.

In a nutshell, spreadsheets are powerful but error-prone at scale, and even small per-cell error rates compound across large planning workbooks. Generic ERP suites are often designed around finance and standard BOM/MRP workflows, not fast rescheduling at machine and operation level or certificate genealogy across concurrent jobs and subcontracted steps.

What a metal fabrication ERP, like EZIIL, does differently?

A focused metal fabrication ERP helps your team move from firefighting to a plan that holds up during the week, with purchasing, shop-floor, and compliance working from the same source of truth. Below is a quick comparison on the key differences between a metal fabrication ERP and a generic ERP:

Planning and scheduling

- Generic ERP or spreadsheets: Limited visibility at machine or operation level; rescheduling is manual and slow when routings or priorities change. In a MTO shop workflow, static plans degrade quickly.

- Metal fabrication ERP: Capacity view across departments and machine-level boards that reflect shop-floor updates in real time so planners can keep dates predictable.

Shop-floor feedback

- Generic ERP or spreadsheets: Status depends on walkarounds, calls, and manual entry, which lags and introduces errors. Spreadsheet research documents compounding error risk in large models.

- Metal fabrication ERP: Operators record time and quantities on mobile with drawings at the station; progress rolls up instantly for planners.

Purchasing, inventory, and reservations

- Generic ERP or spreadsheets: Demand, on-hand, and on-order live in separate places, so buyers miss timing or double-buy during busy periods.

- Metal fabrication ERP: Demand is reconciled with stock and open POs in one screen; buyers raise PRs, convert to POs, and reserve materials to priority jobs.

Traceability and compliance

- Generic ERP or spreadsheets: Certificate files and where-used history are fragmented, which complicates EN 1090 evidence and audits.

- Metal fabrication ERP: Certificates attach to receipts and flow through operations and returns so audits can be satisfied with a clean pack.

Subcontractor steps

- Generic ERP or spreadsheets: Returns, partials, and costs are hard to track against the right operation and job, which affects status and dates.

- Metal fabrication ERP: Send-out, due-back, and partial receipts are tracked with specs and certificates so work re-enters the line without confusion.

5 Signs you’ve outgrown generic ERPs/DYI production management systems

Custom metal fabrication often involves work with many small jobs moving at the same time. Routings change as drawings and priorities evolve, so planners need to reschedule often and still respect the promised deadlines. Frequent and data-driven scheduling decisions dominate the day-to-day performance in custom steel shops. However, this type of workflow is hard to manage with static tools. Some key reasons many custom steel fabricators switched from a generic ERP to EZIIL Enterprise include:

- On-time delivery misses that trace back to last-minute schedule reshuffles and material allocation errors typical of HMLV environments. Improving delivery performance in HMLV requires decision support around lot sizing and scheduling beyond static tools.

- Manual expediting to chase late parts or reassign work, often triggered by supplier slippage. Analyst data shows supplier delivery performance has been volatile, pushing manufacturers to tighten visibility.

- Purchasing blind spots where demand, on-hand, and on-order are not reconciled in one view, leading to shortages or double-buys during busy periods. Persistent labor and supply chain pressure puts even more strain on these gaps.

- Duplicated data to accounting and control issues around spreadsheets. Large models almost always contain mistakes and the risk rises when copying data between files for finance.

- Unmanaged subcontractor returns where partials come back without clean status or certificate linkage. For structural work in Europe and the UK, EN 1090 requires documented traceability of personnel, equipment, and materials with audit oversight, which becomes harder when work leaves the building.

Who is EZIIL Enterprise metal fabrication ERP built for?

EZIIL Enterprise is the ideal fit for custom steel fabrication shops that have outgrown spreadsheets, generic ERPs and light MRPs, and now need one connected system, without the cost/complexity of a heavyweight metal fabrication ERP.

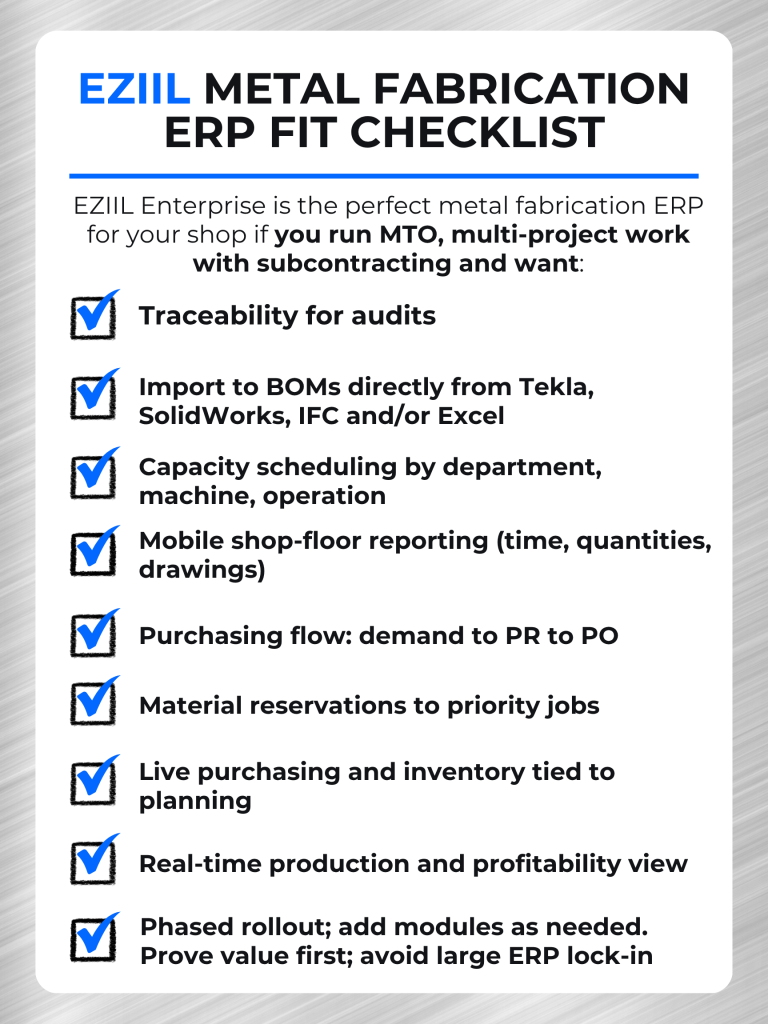

EZIIL metal fabrication ERP fit checklist

Use this quick checklist to see if you are in the sweet spot for EZIIL Enterprise metal fabrication ERP.

EZIIL Enterprise is the perfect metal fabrication ERP software for your shop if:

- You run make to order (MTO) work with multiple projects at the same time and frequent subcontracting.

- You have EN 1090 and traceability needs, including EN 10204 3.1 certificate history.

- You want to import CAD or files to build BOMs and routings (Tekla, SolidWorks, IFC or Excel).

- You need to schedule capacity across departments and at machine and operation level.

- You want to enable your shop floor to report on mobile for time, quantities, drawings and quick notes.

- You want your purchasing to flow from demand to PR to PO, with material reservations to priority jobs.

- You need a real time purchasing + inventory view connected to planning and shop-floor, that shows you what is in stock, on order and allocated to jobs.

- You want live production and profitability overview during execution.

- You prefer to introduce the new ERP system step by step, starting with essentials and adding functions as the team is ready.

- You have outgrown EZIIL Starter and now need a complete production backbone with advanced BOM, planning, inventory, traceability and analytics.

- You want to avoid a large upfront commitment to a generic ERP and would rather prove value first with a flexible monthly subscription plan you can scale.

EZIIL metal fabrication ERP helps the whole team

EZIIL Enterprise connects planning, purchasing, inventory, shop floor, subcontractors, quality, and finance in one place. Engineering handoffs turn into routings and BOMs, schedules reflect live progress, materials are reserved to the right jobs, and finance receives clean references. Everyone works from the same status, so decisions line up and dates/deadlines hold.

Operations and plant leaders

Accountable for promised dates and margin as priorities shift mid-week.

✅ EZIIL provides a single picture of load versus capacity that updates as work moves.

Production planners and line supervisors

Manage many small jobs, frequent routing changes, and tight staffing.

✅ EZIIL offers operation-level boards that reschedule with current progress.

Purchasing and materials managers

Need one view of demand, on-hand, and on-order to avoid shortages and double-buy.

✅ EZIIL links capacity plans to PR and PO actions so orders and reservations match the build plan.

Quality and compliance leads

Must keep traceability and evidence for standards such as EN 1090.

✅ EZIIL organizes certificates and work records by project and operation for audit packs.

Project and commercial teams

Clients expect reliable dates, clear progress, and fewer disputes after delivery.

✅ EZIIL surfaces committed dates, part completion, and package contents without extra shop interruptions.

Controllers and finance leads

Require accurate production references in accounting without changing finance systems.

✅ EZIIL is the single source of truth and lets you export clean data to accounting.

Real outcomes with EZIIL metal fabrication ERP

Many fabricators have moved to EZIIL Enterprise because they want the plan to match the floor and they need proof that decisions improve delivery, materials, and compliance.

With EZIIL, you can expect steadier OTD, earlier course correction, faster buying, tighter material control, audit packs on tap and fewer spreadsheet-driven mistakes.

Here are a few real-life results EZIIL’s users rave about:

More reliable OTD (on-time delivery)

Workflows completed faster, with clearer handoffs and fewer last-minute expedites.

Earlier detection of time and cost overruns

Live planned vs actual hours and materials surfaced issues in time to reallocate, rather than after the fact.

Engineering throughput and onboarding

+40% engineering productivity, and onboarding reduced from about 12 weeks to 1 week (roughly a 92% reduction) by standardizing BOMs, routings and libraries.

Procurement productivity and PO velocity

Increased procurement throughput per buyer 8.6x on average after moving demand→PR→PO into one flow with reservations.

Fewer shortages and expedites

Supply security improved from ~45% to ~98% when demand, on-hand and on-order were reconciled in one view and materials were reserved to priority jobs.

Revenue per head and flow

~30% higher turnover without new hires, after standardizing BOM work and connecting planning to execution.

Document prep and admin load

Engineers cut document prep from about 25% of a project week to near zero by generating complete work packets directly from BOM and routing data.

Audit-ready in minutes

Certificate history and where-used records are packaged per project and operation for audit checks, replacing many disconnected spreadsheets.

Time ROI on BOM work

Teams report about 24× time ROI on BOM effort (1 hour invested yielding ~24 hours saved across procurement and production) once EZIIL templates and libraries are in use.

To sum it up

If your shop is juggling high-mix, make to order work and needs one place for planning, shop floor, purchasing, inventory, subcontractors, and traceability, a metal fabrication ERP is the practical next step. EZIIL Enterprise is built to keep the plan aligned with reality while your accounting stays as it is. The goal is simple: steadier delivery dates, cleaner handoffs, and fewer surprises during the week. Book a demo and lets chat about your specific set up and map out yout needs.