Have you ever been in a tall commercial building and thought about its inner structure? Probably not. That would be like observing an attractive person and wondering what their skeleton looks like!

Steel beams are similar to the bones of a human body in that they maintain the structural shape of the building or body, giving them strength and allowing them to support loads. And another thing they have in common is that they are mostly taken for granted; “out of sight, out of mind” is the appropriate expression.

However, steel beams are an essential framing component of structures such as buildings and bridges. Their weight-bearing characteristics are ideal for supporting floors and roofs, making them the best option for construction and infrastructure projects.

Here are the details:

What do Steel Beams Support?

Image credit: https://theconstructor.org

As mentioned, steel beams are part of a structure’s skeleton or framework, making it strong.

They are often used in construction to support residential and commercial buildings and skyscrapers.

However, their applications encompass other structures, including stadiums, hospitals, bridges, parking garages, and cargo ships.

Metal beams carry the vertical loads above them and can even support horizontal loads to protect against earthquake damage.

Also, you might want to read about Flitch Plate Beams!

What are Steel Beams Made of?

Image credit: https://cbsmn.com

Steel beams are made out of structural steel, an alloy made of iron and carbon. What distinguishes structural steel from regular steel?

The carbon content in steel is too high (0.30% to 0.60%) to be considered structural steel, so it is reduced until the carbon content reaches between 0.05% and 0.25%.

This percentage of carbon is the “sweet spot,” providing structural steel with high strength.

Book a 60-minute demo to see

how eziil mrp solution works for you

What are the Advantages of Using Steel Beams?

Steel beams offer many benefits in construction projects. Here are some of them:

- Durability: Steel beams pass the test of time, and they are solid and will not splinter or warp like timber beams.

- Cost-effective: Steel beams are less expensive than many other materials. A structural engineer sizes the beams for your project, and your contractor orders them. Once they arrive on the worksite, the beams are ready to be installed without labor-intensive prep work.

- Termites or rodents cannot attack them.

- Steel beams are relatively light, weighing less than concrete or timber and reducing transportation fees.

- Steel can endure significant tensile stress, so no bending or breakage issues exist, if calculated properly.

- High-standard structural integrity results in enhanced safety.

- You can have steel beams manufactured to your specific custom sizes.

- Steel beams are resistant to corrosion and fire.

What are the Different Types of Steel Beams?

The following steel beams are classified based on their cross-sections:

Image credit: https://cbsmn.com

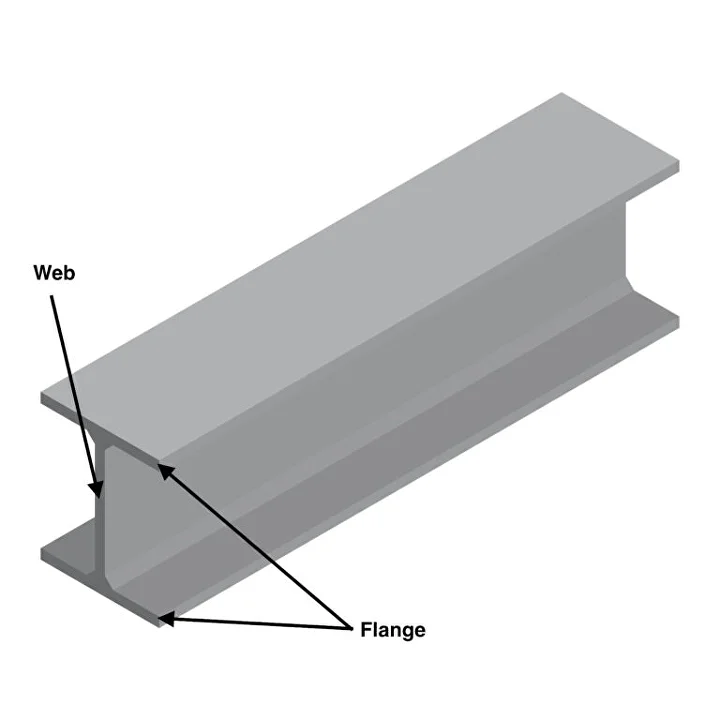

W-beam:

The term ‘W-beam’ stands for ‘wide flange’ beam, a category that includes the popular I-beam and the steel I-beam.

Just like an I-beam, a steel W-beam also has the ‘web’ and the ‘flanges’, making it suitable for bearing heavy loads over large spans.

This is why W-beams, including steel W-beams, are commonly used in large construction projects such as bridges, buildings, and tunnels.

The design of the W-beam closely resembles that of the I-beam, with a key difference being in the width of the flanges. W-beams feature wider flanges, which gives them a slightly different shape and a more substantial bearing surface.

This added surface makes W-beams more resistant to bending, making them an excellent choice for heavy-duty applications.

Image credit: https://cbsmn.com

T-beam:

A T-beam has a T-formed cross-section often used in framing, repairs, and roof trusses, where they can effectively handle heavy loads.

The highest point of the tee beam is a flange or compression member that resists compressive stresses.

The vertical web opposes shear pressure and gives more prominent separation for the coupled bending forces.

The flange forms the top of the ‘T’, while the stem provides vertical support. This structure allows T-beams to efficiently distribute heavy loads.

Image credit: https://cbsmn.com

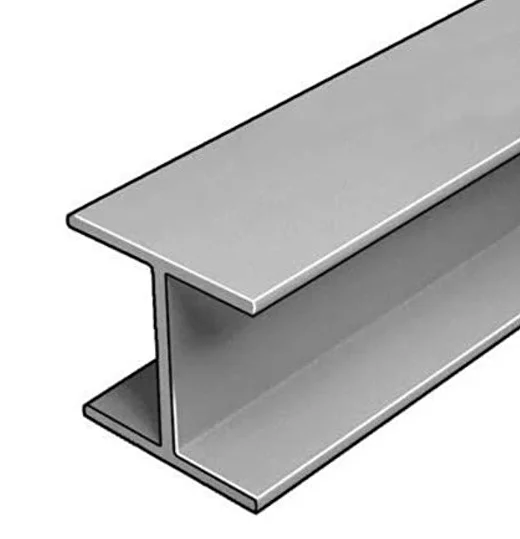

H-beam:

H-beams are a popular type of structural beam. They’re named ‘H-beam’ due to their ‘H’ shape when viewed from the side.

These beams look much like I-beams but are heavier, with wider flanges and thicker central webs.

This structure of the H-beam allows it to withstand larger loads, making the H-beam a preferred choice for heavier structures and high-rise buildings.

Moreover, the wider flange of an H-beam provides a larger surface area, which is particularly advantageous in terms of load distribution.

Thus, H-beams are commonly used in bridge construction and various other structures that require strong horizontal and vertical support.

These features give the beam more carrying capacity than the I-beam.

Image credit: https://cbsmn.com

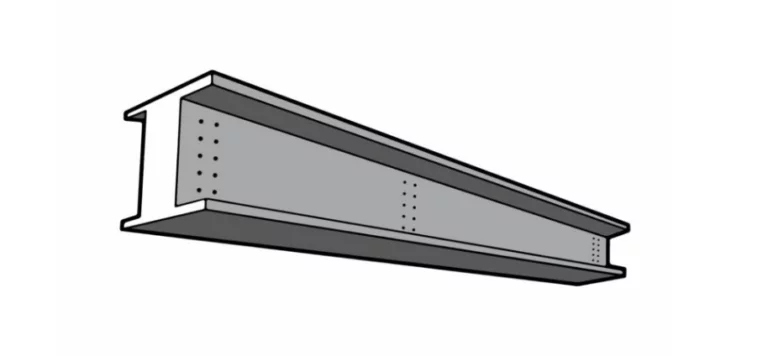

I-beam:

An I-beam is a standard structural steel shape serving as the essential framework for the construction industry. Structural beams are designed with horizontal flanges and a long vertical section called a web, and the material connecting the web to the flanges is called the fillet.

The flanges at the top and bottom of the beam prevent bending, and the web resists blunt force. These components can withstand a maximum bending load with a minimum amount of material while creating the basis of support for high-bearing loads.

I-beams have depth (the distance from top to bottom), width (the flange length), and thickness, referring to the flange and web thickness dimensions.

The mostly-iron I-beam is considered the universal beam because it can support various loads, making it the most common beam in metal structures.

What are Galvanized Steel Beams?

Although structural steel is an excellent building material with a tremendous strength-to-weight ratio, it often requires the extra layer of protection that galvanizing provides.

Galvanized steel beams, specifically galvanized steel I-beams, are a preferred choice in many construction and manufacturing scenarios due to their enhanced durability and resistance.

The term ‘galvanized’ refers to the process of coating the I-beam with a layer of zinc, which prevents corrosion, scratches, and other damage from reaching the steel. This makes galvanized steel I-beams ideal for outdoor structures and environments where moisture is prevalent.

I-beams come in various sizes and lengths, and when these I-beams are galvanized, their life expectancy increases significantly. This is why galvanized steel I-beams are seen as a cost-effective choice for many construction projects.

Galvanized I-beams, like regular I-beams, feature a distinct ‘I’ shape, characterized by a vertical ‘web’ and horizontal ‘flanges’. This shape offers an excellent strength-to-weight ratio, making the I-beam suitable for bearing heavy loads over long spans.

I-beams, especially galvanized steel I-beams, offer enhanced durability and cost-effectiveness. They form a crucial part of various construction and manufacturing projects, providing structural integrity that stands the test of time.

Explore further if you’re interested in “What Are Galvanized Handrails and

Their Uses?”.

Are Steel Beams Expensive?

Steel beams can cost $6-$18 per foot for materials or approximately $100 to $400 per foot installed. These prices do not include extra labor or engineering for surprises or knocking down walls, reinforcing floor joists, or rerouting utilities.

For comparison:

Steel beams are considerably less expensive than wood, ranging from $5 to $90 per foot. Laminated veneer lumber (LVL) costs $3 to $12 per foot or $50 to $100 per foot installed, a little cheaper than steel beams.

Concrete beams are $7 to $16 per foot for materials, with additional soundproofing possible.

The bottom line:

Steel beams are not the most expensive nor the cheapest option. However, they provide all the benefits listed and a few extras, including more headroom in basements, the ability to support enormous loads, span long distances, and hold up over time!