Structural bolts are the unsung heroes of construction and engineering, ensuring the integrity of steel structures, such as skyscrapers and bridges. These specialized structural fasteners bear heavy loads and endure the forces of nature as they play an essential role in safety using bolted connections.

This guide will explain the types of structural bolting, provide bolting specifications, and address the various strengths of structural steel bolts.

What are the Types of Bolts in Steel Structures?

Among the various types, the most commonly used structural bolts include:

- A325 Bolts: Often used in structural steel connections, these heavy-duty bolts are known for their strength and reliability. They are in buildings, bridges, and other structures requiring a high load capacity.

- A490 Bolts: Similar to A325, A490 bolts offer even higher strength and are in connections requiring stringent control over the bolt’s mechanical properties.

- Tension Control (TC) Bolts: Also known as twist-off bolts, TC bolts provide high tension precision, making them suitable for heavy construction where proper bolt tension is crucial.

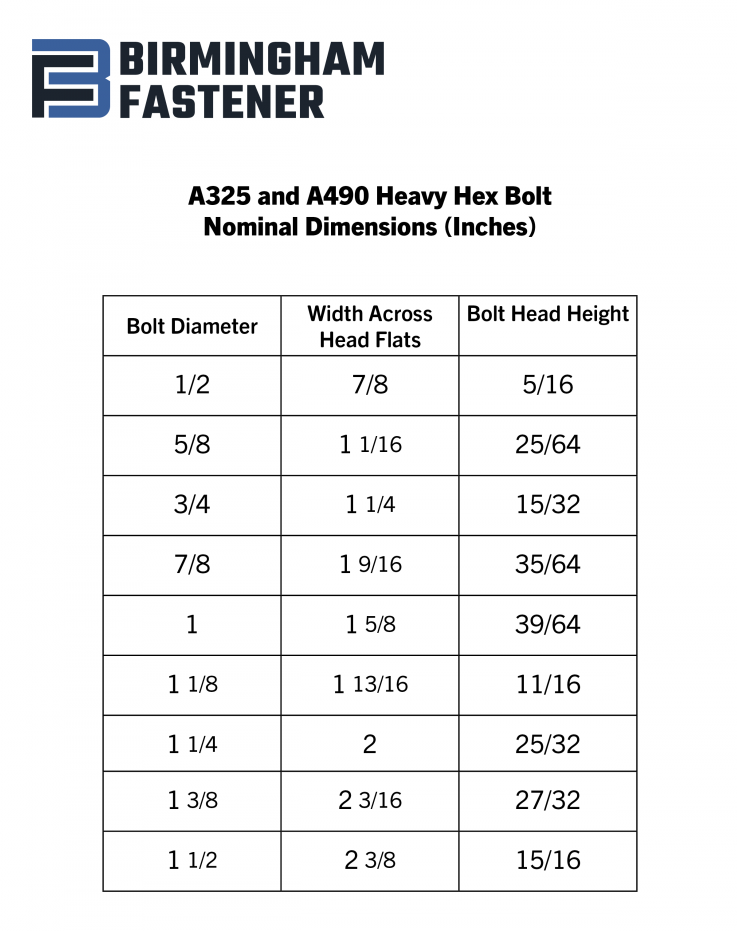

- Heavy Hex Bolts: These bolts have a thicker head than standard hex bolts and offer a larger bearing surface that distributes the clamping load over a wider area. Characterized by their six-sided, hexagonal head, these bolts work well in high-strength and temperature applications.

Each type of structural bolt serves a unique purpose within construction and engineering projects, tailored to specific needs regarding strength, tension control, and application environment.

How are a Structural Bolt’s Dimensions and Sizing Determined?

The dimensions and sizing are determined based on specific standards that consider the application’s load requirements, the material’s properties, and safety factors. These standards, such as ASTM (American Society for Testing and Materials) in the United States, specify the bolt diameters, length, thread pitch, and strength grade necessary for different construction scenarios.

The diameter and length of a bolt are chosen based on the material’s thickness–called “grip”– being joined and the type of load (tension or shear) the bolt will bear. Thread pitch affects the bolt’s resistance to loosening under vibration, while the strength grade, often marked on the bolt head, indicates the bolt’s yield and tensile strength. This approach ensures that each bolt will perform as needed to maintain the integrity and safety of the structure.

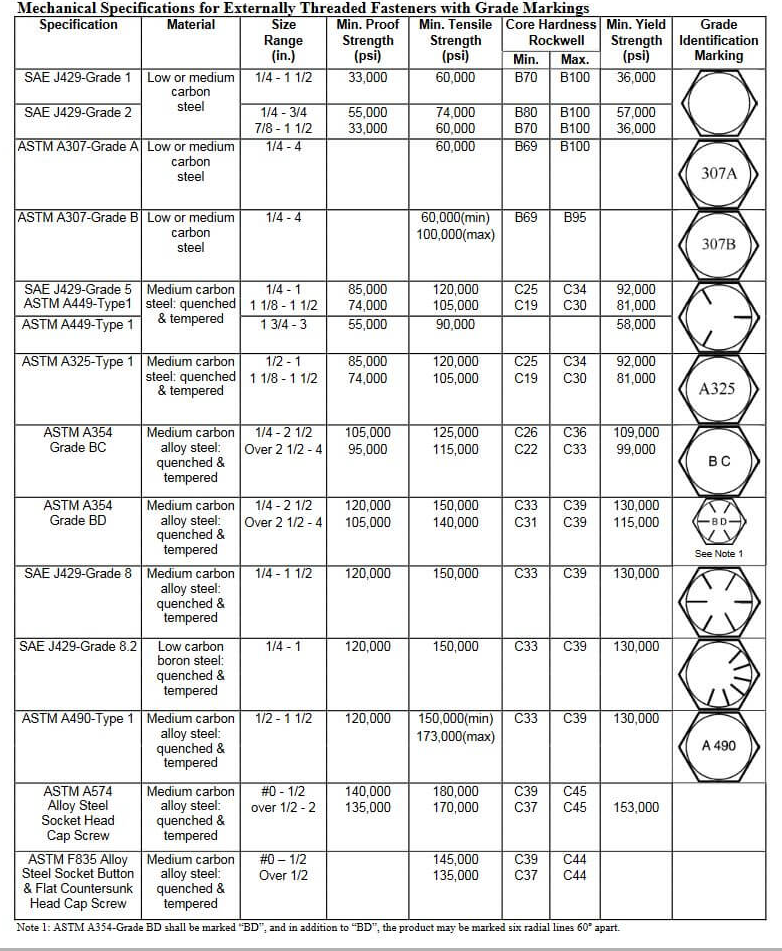

What are the Criteria for Strength in a High-Strength Bolt?

The primary grading systems for higher-strength structural bolts are the American Society for Testing and Materials (ASTM) and the Society of Automotive Engineers (SAE). These systems classify bolts based on their material properties, including tensile strength, yield strength, and proof load. For example, ASTM A325 and A490, mentioned earlier, are commonly used for structural steel connections, with A325 bolts designed for standard application needs and A490 bolts offering higher strength.

Similarly, the SAE grading system uses grades such as Grade 5, Grade 8, and Grade 9, where Grade 9 signifies bolts of the highest strength level, suitable for demanding applications requiring significant load-bearing support.

Book a 60-minute demo to see

how eziil mrp solution works for you

How are Bolts for Structural Steel Connections Selected?

A325 bolts are high-strength bolts for structural steel connections. These bolts are made from quenched and tempered carbon steel and have specific characteristics, making them ideal for heavy-duty construction applications. They are available in diameters from 1/2 inch to 1-1/2 inches and are used in tension and shear connections. Depending on the bolt diameter, the bolt tensile strengths range from 105,000 to 120,000 psi. The A325 bolts specifications also mandate a minimum elongation of 14% for bolts shorter than four times the diameter and 12% for bolts longer than four diameters, ensuring sufficient flexibility in structural applications.

Although Grade 9 bolts are not part of the SAE grading system, they are one of the strongest bolts with a tensile strength of 180,000 psi, compared to the 150,000 psi tensile strength of grade 8 bolts. The SAE Grade 5 bolt strength is equivalent to the A325 bolt’s strength.

Installing Bolts for Structural Steel Applications

Although selecting the proper structural bolt is critical, choosing the appropriate installation method for high-strength fasteners is also essential.

Below are simplified overviews of two standard installation techniques:

- Turn-of-Nut Method: Rotate the nut or the bolt head to a pre-determined angle calculated by considering its length and diameter while ensuring the opposite end remains fixed during tightening.

- Calibrated Wrench Method: Tighten the fastener using a torque wrench set to a precise value. Determine this value by daily testing with a setup that mirrors actual working conditions as closely as possible.

Each approach can ensure your bolted connections are secure and reliable.

What are Some of the Innovations and Trends in Structural Bolting?

- Self-Tightening Nuts: These innovative nuts maintain tension under vibration, preventing loosening in high-vibration environments.

- Corrosion-Resistant Coatings: Advances in coatings such as zinc flake, which are both environmentally friendly and highly effective at preventing corrosion, extend the lifespan of bolts in harsh conditions.

- Tension Control Bolts (TC Bolts): These bolts have a built-in feature that indicates when the bolt has reached the correct tension, ensuring structural integrity.

- Hybrid Bolting Materials: The development of new materials that combine steel’s strength with aluminum’s weight savings or titanium’s durability offers the potential for lighter, more robust structures.

Digital Torque Tools: Sophisticated tools to ensure the correct tightening of bolts help to improve safety and reliability.

Final Thoughts on the Role of Structural Bolts

Structural bolts are a fundamental part of construction and engineering, offering strength, reliability, and durability. Their application in building bridges, skyscrapers, and other critical infrastructures stresses their crucial role in ensuring safety and stability.

With technological advancements, producing and testing these bolts have significantly improved and offer even greater performance assurance. Understanding structural bolt types, specifications, and proper installation techniques is essential for architects, engineers, and construction professionals.

By prioritizing quality and adherence to standards, construction businesses can maintain the integrity of their structures, safeguarding lives and investments.