If you are a structural steel fabricator, you know that having an estimator on staff is a key to your success. You must understand the key responsibilities and considerations involved in the role of a structural steel estimator. This blog post will discuss some of the most important aspects of being a successful structural steel estimator. We hope this information will help you understand the role of the structural steel estimator.

What is a Structural Steel Estimator?

A structural steel estimator is responsible for accurately costing all structural steelwork associated with construction or manufacturing projects. This will involve working closely with architects, engineers, and construction managers to identify the type, quantity, and quality of steel required for each project.

You will also need to keep up to date with the latest developments in steel technology and pricing to provide accurate estimates. In addition to your technical knowledge, as a structural steel estimator, you will also need excellent negotiation and communication skills in order to secure the best possible price for your clients.

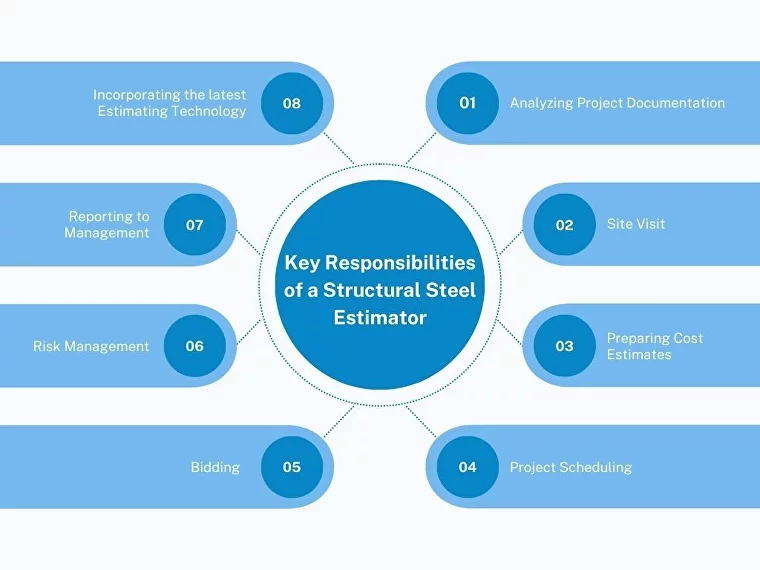

Key Responsibilities of a Structural Steel Estimator

Some of the key responsibilities of a structural steel estimator include:

- Analyzing Project Documentation

The estimator will review the project documentation, such as blueprints, drawings, and specifications, and understand the scope of work. This includes identifying the type and quantity of steel required for the project.

- Site Visit

A visit to the project site is important to better understand the environment and conditions in which the steel will be used. This information is important for determining the steel grade best suited for the project.

- Preparing Cost Estimates

After gathering all relevant information, the structural steel estimator will prepare a cost estimate for the project. This estimate will include the cost of materials, labor, equipment, and other associated expenses. Direct and Indirect costs should also be considered. The final estimate also includes a margin for profit and overhead costs.

- Project Scheduling

The project schedule takes into account the time required for fabricating, delivering, and erecting the steel on site. The project estimator is also responsible for considering any potential delays in the estimation that could impact the project schedule.

- Bidding

After the estimator has prepared the cost estimate and project schedule, a bid will be compiled. This bid will be submitted to the client and the estimator’s proposal for the project. Important things to consider when bidding on a project include the timeline, price, and terms and conditions.

- Risk Management

There are several risks associated with any structural steel project. The estimator needs to identify and assess these risks before bidding on the project. This includes risks related to material availability, price fluctuation, labor shortages, and weather conditions. Commonly neglected risks include the potential for errors and omissions.

- Reporting to Management

The structural steel estimator is also responsible for timely reporting to the management. This includes progress reports, invoices, and change orders. The estimators may also be required to present their findings to the project manager or other members of management.

- Incorporating the latest Estimating Technology

As with any profession, the estimating field is constantly evolving. Estimators need to stay up-to-date with the latest software and technology. This includes learning to use new estimating software and platforms like Eziil.

Book a 60-minute demo to see

how eziil mrp solution works for you

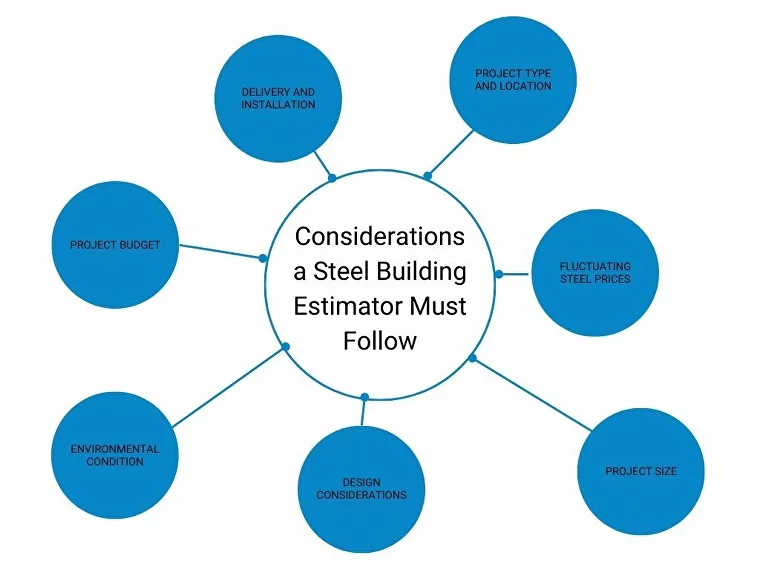

Some Considerations a Steel Building Estimator Must Follow

Now that we’ve outlined the role of a structural steel estimator let’s look at some of the key considerations that need to be made when ordering or estimating steel for a project.

1. Project Type and Location

The type of project will have a big impact on the type of steel that is required. For example, a high-rise office building will require a different type of steel than a factory. The location of the project is also important to consider. Projects in coastal areas need to account for salt air and corrosion, while projects in cold climates need to account for freezing temperatures.

2. Fluctuating Steel Prices

Another important consideration is the price of steel. The steel price can fluctuate greatly, depending on several factors, such as the current market conditions, material availability, and the quantity needed. Structural steel estimators need to be aware of these fluctuations and account for them in their estimates.

3. Project Size

When ordering, it is important to consider the size of the project. The quantity of steel required will be based on the size of the project. This includes the dimensions of the building, the height of the ceilings, and the thickness of the walls.

4. Design Considerations

As a structural steel estimator, it is important to consider the project’s design when creating your estimate. This includes everything from the project’s overall layout and size to the specific steel grade that will be used. By taking all of these factors into account, you will be able to create a more accurate estimate that will help ensure the project’s success.

5. Environmental Condition

The environment is one of the most important – and often overlooked – factors that steel estimators must consider. Inclement weather conditions can delay construction, impact material availability, and drive up costs. As such, it’s essential to consider environmental conditions when estimating the cost of a project.

6. Project Budget

It is important to consider the project budget when bidding on a project. If the budget is too low, it may not be possible to complete the project within the specified timeframe or to meet all the required specifications. On the other hand, if the budget is too high, the project may cost more than necessary. Therefore, it is important to strike a balance when considering the budget for a structural steel estimation project.

7. Delivery and Installation

When it comes to the delivery and installation of a structural steel project, there are a few key things that estimators need to keep in mind. First and foremost, it is important to ensure that the delivery date is realistic and that there is enough time for installation. Secondly, the estimator needs to consider the logistics of the delivery itself, including the route, the number of trucks required, and any potential obstacles. Finally, the estimator should also be aware of the installation process and ensure an adequate workforce and equipment are available.

Benefits of Choosing an experienced Structural Steel Estimator

Any successful project starts with a well-constructed estimate. An experienced structural steel estimator can provide this level of accuracy, ensuring that your project stays on budget and schedule. Furthermore, a professional estimator will have a network of suppliers and subcontractors, which can help to reduce costs.

In addition, a certified estimator is familiar with the latest trends and regulations. The estimator ensures that your project meets all relevant standards and is on the way to a solid start.

Conclusion

A structural steel estimator is a very important part of any structural steel fabrication company. The estimator’s job is to ensure that the cost of all the steel work associated with the project is accurately calculated. By incorporating the latest estimating technology into his workflow, he can streamline this process and ensure accuracy.

Eziil is the latest MRP software for custom metal fabrication companies. It completely digitizes your production process by providing real-time data from project planning to execution. The software also assists in project cost estimation, inventory, and risk management. If you are interested in learning more about how Eziil can assist you in project estimation, please don’t hesitate to contact us. We would be happy to answer any questions you may have.