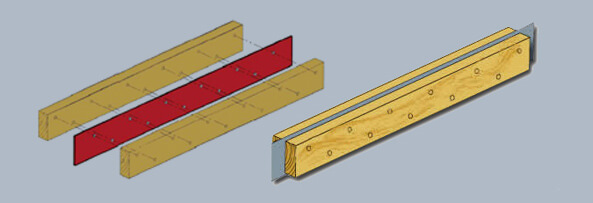

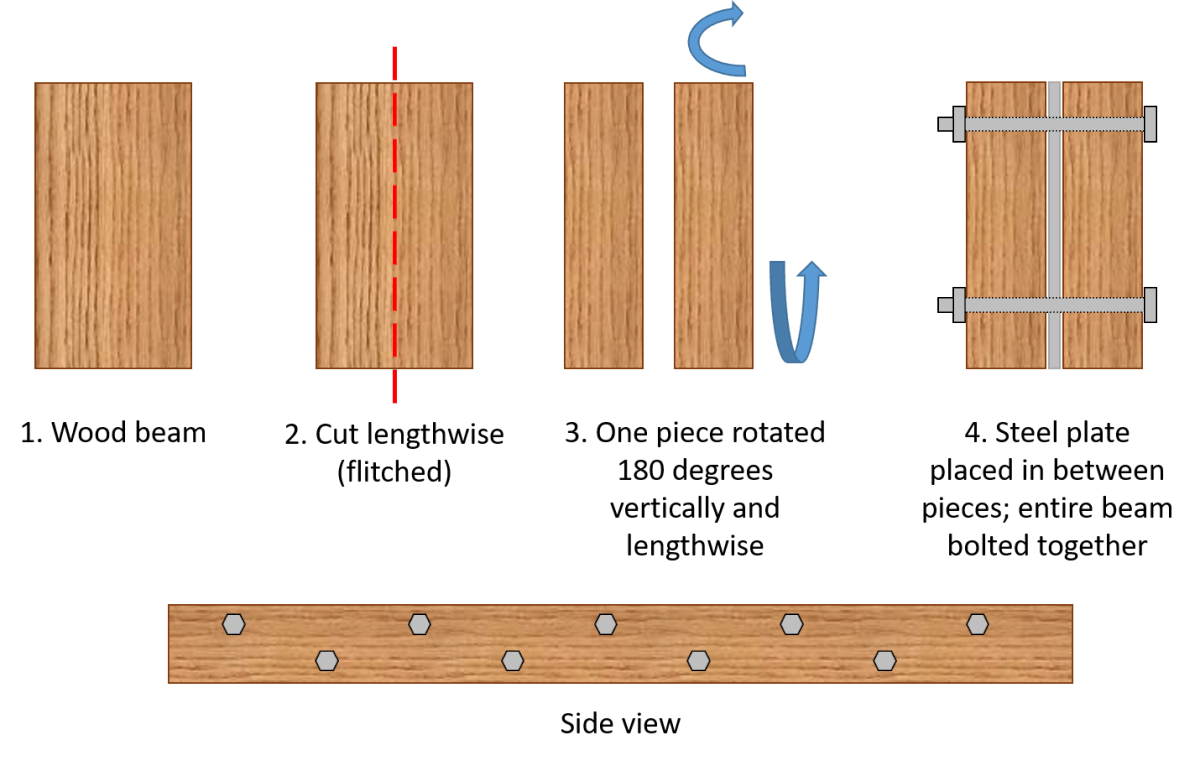

Flitch beams, also known as flitch plates, are beams that are comprised of steel and wood members, with the steel being placed in the center and wood members on either side in order to ‘sandwich’ the steel beam.

The outer wood pieces are typically glued to the steel beam with adhesives, and then bolted to each other across the length to increase the integrity of the bond and reinforce the beam assembly.

These beams are used as structural supports in a variety of applications, but their popularity and effectiveness are being reduced as more modern materials enter the construction space and provide better solutions for specific applications.

See below for a visual of what a flitch beam assembly looks like.

Image credit: http://www.urcreativespace.co.uk

Why are Flitch Beams Made?

Flitch beams are made in order to be used in framing applications such as floor framing, wall framing, roof trusses, and heavy load support requirements.

Beams provide and effective solution for situations that require loads be evenly distributed across multiple, parallel supports.

The wood provides insulation from naturally occurring heat transfer for the steel plate, which is in place to provide additional strength to the beam.

Beams can have multiple layers beyond the standard steel plate sandwiched by two wood beams – in other words, multiple ‘stacks’ of steel plate and wood beam combinations can be bound together to create stronger members as required for each situation.

Image credit: https://en.wikipedia.org

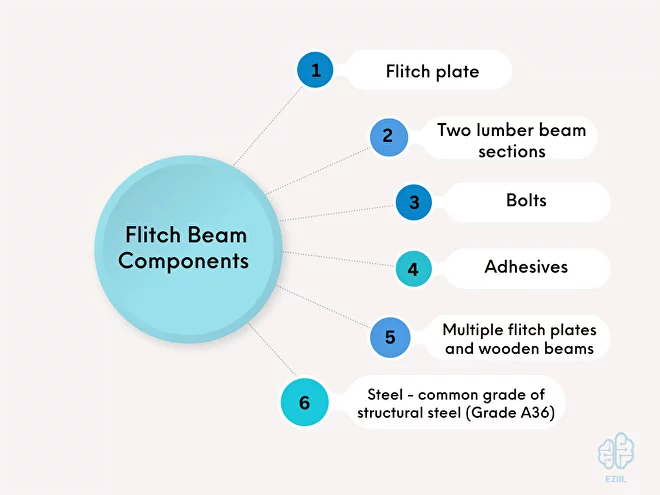

Flitch Beam Components

• The most obvious part used in a flitch beam is the flitch plate, which is the steel member that is sandwiched between the two lumber beams.

• Two lumber beam sections are also used in a standard flitch beam assembly, and these sit on the outside of the flitch plate and are ‘sandwiched’ onto steel section.

• Bolts are used throughout the beam to fasten the outer wood components to the steel plate.

• Adhesives are typically applied to the inner faces of the outside wood beams as well to add an additional layer of bonding between the components.

• Depending on the needs of beam, multiple flitch plates and wooden beams can be used to create a stacked series of beams to increase the overall strength of the assembly. This is typically done in special applications and is not the ‘standard’ flitch beam design.

• The steel found in flitch beams is typically ½”, ¾”, or 1″ thick hot rolled sections topping out around 20 feet in length. The steel itself is usually the most common grade of structural steel available on the market, which is Grade A36.

Where Flitch Beams are Used

Flitch beams are versatile structural elements commonly used in various construction and mechanical engineering projects. Combining the advantages of both timber and steel, these beams consist of two or more pieces of lumber, usually bolted or otherwise fastened together, sandwiching a flitch plate in the middle. The flitch plate, typically made of steel, enhances the strength, stiffness, and load-bearing capacity of the overall structure. The unique design of flitch beams makes them suitable for a wide range of applications, some of which will be discussed below.

Residential Construction

Flitch beams are commonly used in residential construction projects, such as home renovations and extensions, where they provide support for added loads. The flitch plate improves the rigidity of the beam, enabling it to carry more weight than a timber beam of similar dimensions. Consequently, flitch beams are ideal for creating large, open spaces in homes, as they can span greater distances without requiring additional support columns or posts.

Commercial Construction

Flitch beams have found a place in commercial construction as well. They are used in the construction of office buildings, retail outlets, and warehouses, where they provide superior strength and rigidity for the building’s framework. The flitch plate’s steel component allows for a thinner and more lightweight beam, making it a popular choice for architects and engineers who aim to create aesthetically pleasing designs without compromising on structural integrity.

Floor Joist Systems

In both residential and commercial construction, flitch beams are frequently used as part of floor joist systems. These systems are designed to support the weight of a building’s floor and distribute the load evenly across the entire structure. By incorporating a flitch plate into the design, engineers can increase the load-bearing capacity of the floor joists, allowing for the creation of more extensive and open living or working spaces.

Roof Support Structures

Flitch beams are also utilized in roof support structures, where their unique combination of wood and steel offers an excellent balance of strength, stiffness, and weight. The flitch plate’s steel reinforcement prevents the wood from warping or twisting, ensuring the roof’s stability and longevity. Flitch beams are particularly useful in regions with heavy snowfall, where the additional strength and rigidity provided by the flitch plate help to resist the snow load.

Industrial Applications

In the realm of mechanical engineering, flitch beams are employed in various industrial applications, such as machine frames, conveyor systems, and gantry cranes. The flitch plate’s presence enhances the overall durability and performance of these structures, allowing them to withstand the harsh conditions of an industrial environment.

Plate beams, consisting of a web plate and two flange plates, are versatile structural elements used in construction and mechanical engineering projects. High-quality materials, such as those provided by Allied Steel, are essential for the success of plate beams.

Key applications of plate beams and Allied Steel products include:

- Bridge Construction: Plate beams serve as primary load-bearing components, with Allied Steel’s strength and durability ensuring long-lasting structures.

- Building Frameworks: In commercial and industrial projects, plate beams, using Allied Steel, support large, open spaces without excessive support columns.

- Crane Systems: Plate beams are utilized in crane systems, such as gantry and overhead cranes. Allied Steel products ensure reliability and performance.

- Machine Frames: Plate beams are integral to machine frames, housing mechanical components. Allied Steel’s quality ensures endurance and reduced maintenance costs.

- Structural Retrofitting: Plate beams are used to reinforce or replace existing structures. Allied Steel products enhance load-bearing capacity and stability.

In conclusion, plate beams are vital structural elements in various fields, and the use of high-quality steel products from Allied Steel ensures their reliability, durability, and performance.

Book a 60-minute demo to see

how eziil mrp solution works for you

Flitch Beam Sizes

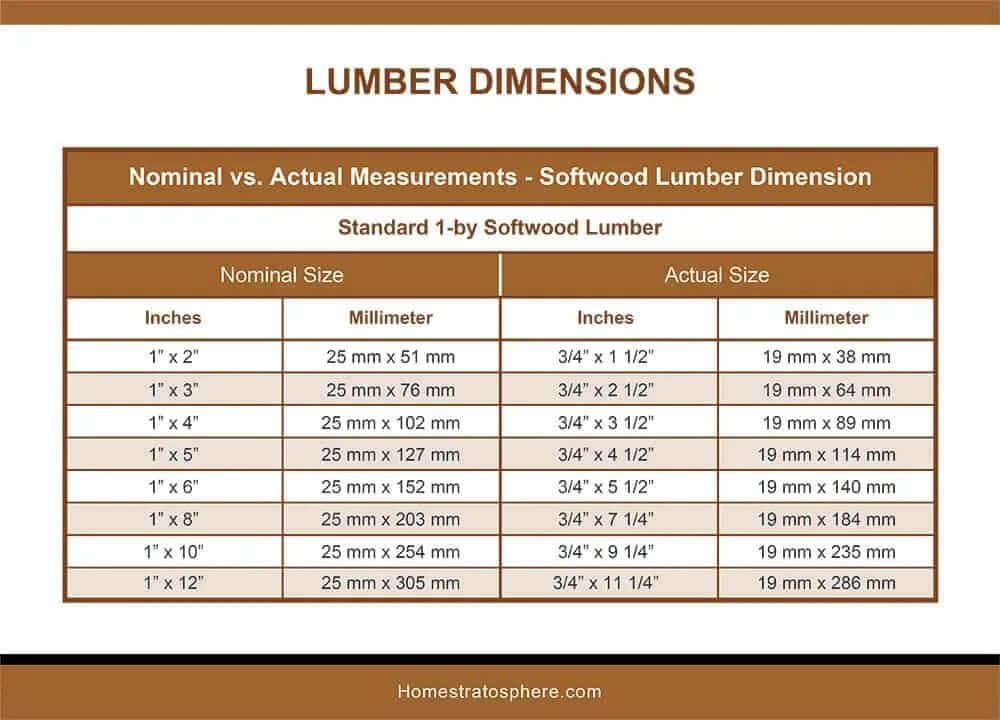

Flitch beams can be made into any custom size that the application calls for, but there are also standard size offerings on the market. Flitch beam widths are typically in line with dimensional lumber beams, starting commonly at 2×6, 2×8, 2×10, and 2×12 sizes. Overall length of the beams are dependent upon design and application, but 20 feet long beams are a common length found by most manufacturers. This length is also dependent upon the length of wood and steel members commonly sold, which range from 8 feet all the way to 24 feet and 40 feet in some more specialized offerings.

Common lengths of flitch beams, as dictated by common dimension lumber lengths, can be seen below:

Flitch Beam Benefits

Flitch beams are lighter and cheaper than beams made entirely of steel, and they also allow builders to easily affix lumber pieces to them thanks to the presence of the wooden beam sides.

These wood sides allow for common construction fixtures to be used like nails or screws, which further reduces overall cost during the build process due to time reduction and component cost reduction.

Flitch beams are also more narrow than their pure wood counterparts, which allows for the benefits of wood to be realized in tighter space constraints that may have other wise required steel beam supports.

As stated before, flitch beams also provide the benefit of being easier to ‘drop’ into old construction restoration projects the require wood mounting surfaces or aesthetic looks.

With the versatility of strength compared to size, flitch beams are a great solution to restoration challenges as they appear.

Flitch Beam Disadvantages

Flitch beams are not perfect solutions to every problem, and they come with their share of disadvantages.

The primary disadvantage of the flitch beam is that its effectiveness is surpassed by more modern beams like glulam beams that use modern adhesives and high strength engineered materials.

Further, as labor costs increase, the cost efficiency of flitch beams decreases as they require more time to assemble and build.

With labor costs increasing rapidly in the modern world, flitch beams are becoming less and less practical from a cost perspective.

Flitch beams are also heavier than newer engineered wood solutions that provide the same or greater levels of support.

Conclusion

Flitch beams are a practical and effective way to reinforce or replace structural support members of older construction homes due to their strength to width ratio as well as their ability to display a wooden exterior that achieves particular aesthetic requirements as well as wooden fixturing methods such as nailing and screwing.

These beams can be made on the fly at the job site if needed, which gives them both versatility but additional labor cost than traditional beams that are ready to go once they arrive.

Flitch beams are becoming obsolete with modern laminated beams and engineered wood members, but their niche applications keep the present in the construction industry and that is where they will remain for the foreseeable future.