From aluminum to titanium, these remarkable materials possess unique properties and find wide-ranging applications across various industries.

A professional creative article writer and an expert in product design, a mechanical engineer, and a metal manufacturing expert often encounter various materials in work. Among these, non-ferrous metals are a fascinating and essential category that is highly sought after in many industries.

In this extensive guide, we will explore what non-ferrous metals are, their properties, common examples, and their applications in different fields.

What is Non-Ferrous Metal: A Definition

Non-ferrous metals are a category of metals that do not contain significant amounts of iron, distinguishing them from their ferrous counterparts.

The term “non-ferrous” comes from the Latin word “ferrum,” which means iron, and the prefix “non-” denotes the absence of iron.

Consequently, non-ferrous metals do not possess the magnetic properties typically associated with iron-containing metals, such as steel.

When exploring the fascinating realm of non-ferrous metals, one cannot overlook the enduring elegance of wrought iron. Unlike its ferrous counterparts, wrought iron is a non-ferrous metal that exhibits exceptional strength, malleability, and a distinct aesthetic appeal. From decorative gates and ornamental fences to intricate furniture designs, wrought iron has been a beloved choice for centuries, showcasing its timeless charm and versatility.

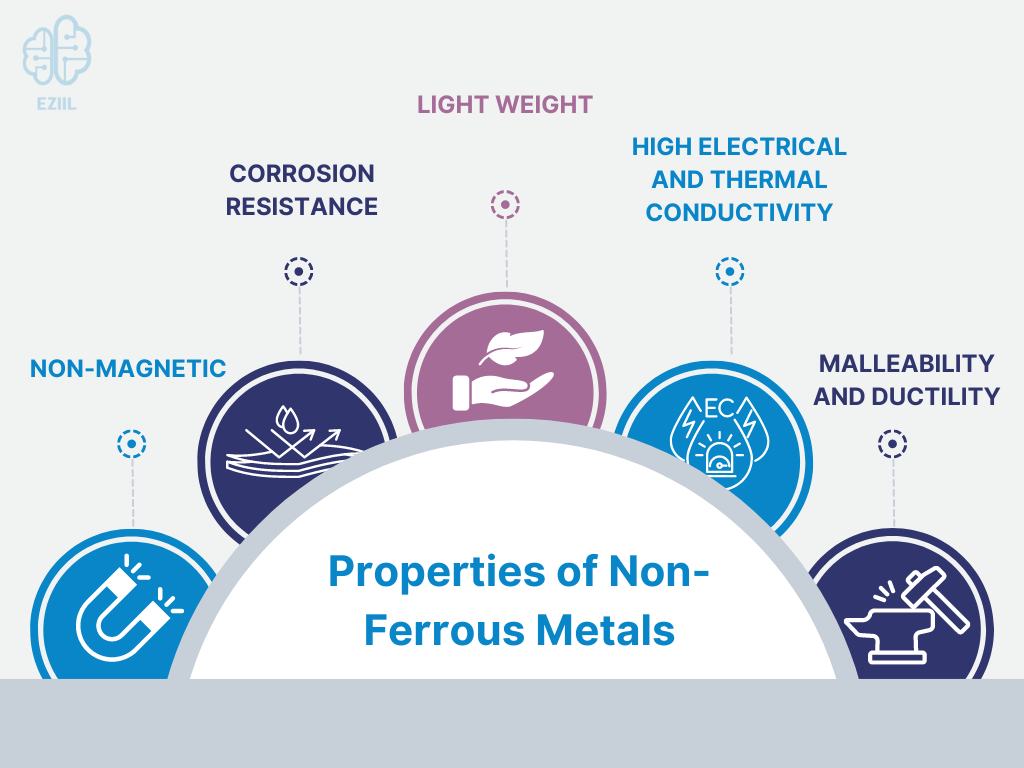

Properties of Non-Ferrous Metals

Non-ferrous metals possess several unique properties that make them highly desirable in various applications. Some of the most notable characteristics of non-ferrous metals include:

- Non-Magnetic: Due to the absence of iron, non-ferrous metals do not exhibit magnetic properties, making them suitable for applications where magnetic interference must be avoided, such as in electronic devices and MRI machines.

- Corrosion Resistance: Many non-ferrous metals, such as aluminium and copper, are naturally resistant to corrosion, making them ideal for use in harsh environments and outdoor applications.

- Light Weight: Non-ferrous metals like aluminium and magnesium are lightweight, offering strength-to-weight ratios that outperform many ferrous metals. This characteristic makes them popular choices in the automotive and aerospace industries, where weight reduction is critical.

- High Electrical and Thermal Conductivity: Non-ferrous metals such as copper and silver are known for their excellent electrical and thermal conductivity, making them the materials of choice for electrical wiring, heat sinks, and other heat transfer applications.

- Malleability and Ductility: Many non-ferrous metals, like copper and gold, can be easily shaped and formed without breaking, allowing for the creation of intricate designs and components.

Common Examples of Non-Ferrous Metals and Their Applications

Some examples of Non-Ferrous Metals and their applications are as follows:

1. Aluminium: Aluminium is a lightweight, corrosion-resistant metal that is used in a wide range of applications, including aerospace, automotive, and construction. Its low density, combined with its high strength-to-weight ratio, makes it an excellent choice for reducing weight without sacrificing structural integrity.

Aluminium is also a popular material for packaging, such as beverage cans and foil.

2. Copper: Known for its high electrical and thermal conductivity, copper is widely used in electrical wiring, motors, and transformers. Additionally, it is used in plumbing, metal roofs, and heat exchangers due to its corrosion resistance and malleability

3. Brass: Brass is an alloy of copper and zinc and is characterised by its gold-like appearance and excellent corrosion resistance.It is commonly used for decorative purposes, as well as in musical instruments, plumbing fixtures, and electrical fittings.

Bronze bearings

It is known for its hardness, durability, and resistance to corrosion. Bronze is often used in the production of bearings, bushings, and gears, as well as in artistic sculptures and architectural elements.

5. Zinc: Zinc is primarily used as a protective coating for steel and iron, known as galvanizing, which prevents corrosion and extends the life of these materials.

Additionally, zinc is used as an alloying element in brass and bronze, as well as in the production of batteries, die-casting, and as a component in various chemicals and pharmaceuticals.

6. Titanium: Titanium is a strong, lightweight, and corrosion-resistant metal that is often used in aerospace, automotive, and medical applications.

Its exceptional strength-to-weight ratio and biocompatibility make it an ideal material for prosthetics, implants, and surgical instruments. Additionally, titanium’s resistance to corrosion allows it to perform well in chemical processing and marine environments.

7. Magnesium: Magnesium is another lightweight non-ferrous metal with a high strength-to-weight ratio. It is used in applications where weight reduction is crucial, such as in the automotive and aerospace industries.

Magnesium is also used in the production of electronic devices, cameras, and sporting equipment due to its light weight and ability to dissipate heat.

Book a 60-minute demo to see

how eziil mrp solution works for you

Ferrous vs. Non-Ferrous Metals: Understanding the Difference

The primary difference between ferrous and non-ferrous metals lies in their iron content. Ferrous metals, such as steel and cast iron, contain significant amounts of iron and exhibit magnetic properties. Non-ferrous metals, on the other hand, have little to no iron content and are not magnetic.

This distinction between ferrous and non-ferrous metals directly impacts their properties and applications. Ferrous metals, like steel and cast iron, are known for their strength and durability but can be susceptible to rust and corrosion. Non-ferrous metals, such as aluminium and copper, offer corrosion resistance, lighter weight, and other unique properties that make them suitable for a wide range of applications.

Ferrous Material Example: Steel

Steel is a prime example of a ferrous material. It is an alloy of iron and carbon, often combined with other elements to enhance specific properties.

Steel is known for its strength, durability, and versatility, making it a popular material in construction, automotive, and countless other industries.

Stainless steel, despite its name, is considered a non-ferrous metal within the broader category. It is an alloy primarily composed of iron, chromium, and other elements, but the absence of significant iron content sets it apart from ferrous metals. As a result, stainless steel does not exhibit the magnetic properties commonly associated with iron-based metals. This makes stainless steel highly versatile and sought after in various industries, thanks to its exceptional corrosion resistance, durability, and aesthetic appeal.

Non-Ferrous Metals in the Recycling Industry

In addition to their numerous applications, non-ferrous metals also play a significant role in the recycling industry.

Due to their valuable properties and relatively low abundance in the Earth’s crust, non-ferrous metals are highly sought after by recyclers.

Recycling not only helps conserve these precious resources but also reduces the environmental impact associated with mining and refining raw materials.

Some common examples of recycled non-ferrous metals:

Some common examples of recycled non-ferrous metals are as follows:

- Aluminium: Aluminium recycling is a well-established practice, with recycled aluminium being used to produce new aluminium products, such as cans, automotive components, and construction materials. Recycling aluminium saves up to 95% of the energy required to produce aluminium from raw materials.

- Copper: Copper is another non-ferrous metal that is highly recyclable. Recycled copper is used in various applications, including electrical wiring, plumbing, and roofing. The recycling process for copper is highly efficient, preserving approximately 90% of its original properties and reducing energy consumption by up to 85% compared to primary production.

- Lead: Lead is a highly recyclable non-ferrous metal, commonly found in batteries, pipes, and other applications. The recycling process for lead is straightforward, recovering up to 99% of the original material while consuming significantly less energy than primary production. Recycled lead is used in new batteries, protective shielding, and other products.

- Precious Metals: Precious metals, such as gold, silver, and platinum, are highly valuable and often recovered from electronic waste and other sources. These metals are easily recycled, and the reclaimed material can be used in new electronic components, jewellery, and other applications. Recycling precious metals reduces the demand for environmentally harmful mining practices.

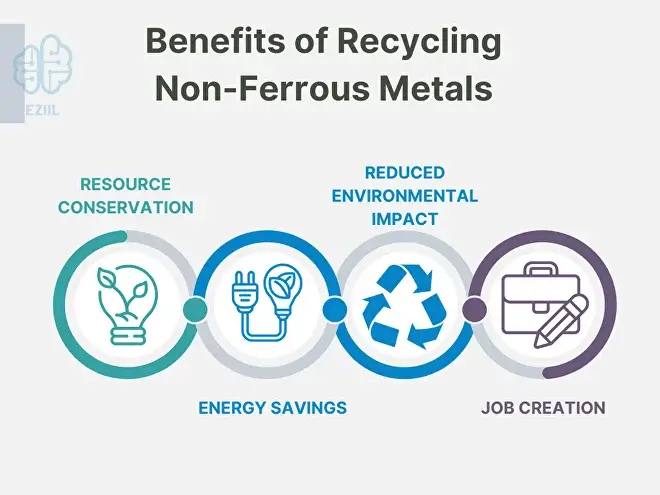

Benefits of Recycling Non-Ferrous Metals

- Resource Conservation: Recycling non-ferrous metals helps conserve valuable resources by reducing the demand for raw materials. This is particularly important for metals like copper and aluminium, which have limited reserves and are essential for modern technology.

- Energy Savings: The process of recycling non-ferrous metals is typically more energy-efficient than extracting and refining raw materials, resulting in significant energy savings.

- Reduced Environmental Impact: Recycling non-ferrous metals reduces the need for mining and refining, which can cause environmental harm through deforestation, soil erosion, and water pollution. Furthermore, recycling helps decrease the volume of waste in landfills, reducing the potential for groundwater contamination and other negative environmental consequences.

- Job Creation: The recycling industry, particularly for non-ferrous metals, creates numerous job opportunities in collection, processing, and manufacturing. This, in turn, contributes to local economies and promotes sustainable development.

Conclusion

Non-ferrous metals are an essential and versatile group of materials with a wide range of applications. Their unique properties, coupled with their recyclability, make them an indispensable component of modern industry and sustainable development.

By understanding the importance of non-ferrous metals, their applications, and the benefits of recycling, you can contribute to a more sustainable and efficient world.

Whether you are a professional in product design, mechanical engineering, or metal manufacturing, having a comprehensive understanding of non-ferrous metals will undoubtedly enhance your expertise and help you navigate the ever-changing landscape of engineering and manufacturing.