There are a variety of important certifications for steel fabricators. Some certifications focus on the fabrication process, while others focus on specific types of steel products and safety.

Any certification signifies that the steel fabricator has met specific requirements regarding education, training, and experience with metalworking processes and products.

Earning certifications can help set the business apart from competitors and show customers quality workmanship. Read more to learn about some important certifications for steel fabricators.

1. AISC (American Institute of Steel Construction) Certification

The American Institute of Steel Construction (AISC) is a not-for-profit technical institute and trade association for the fabricated steel industry.

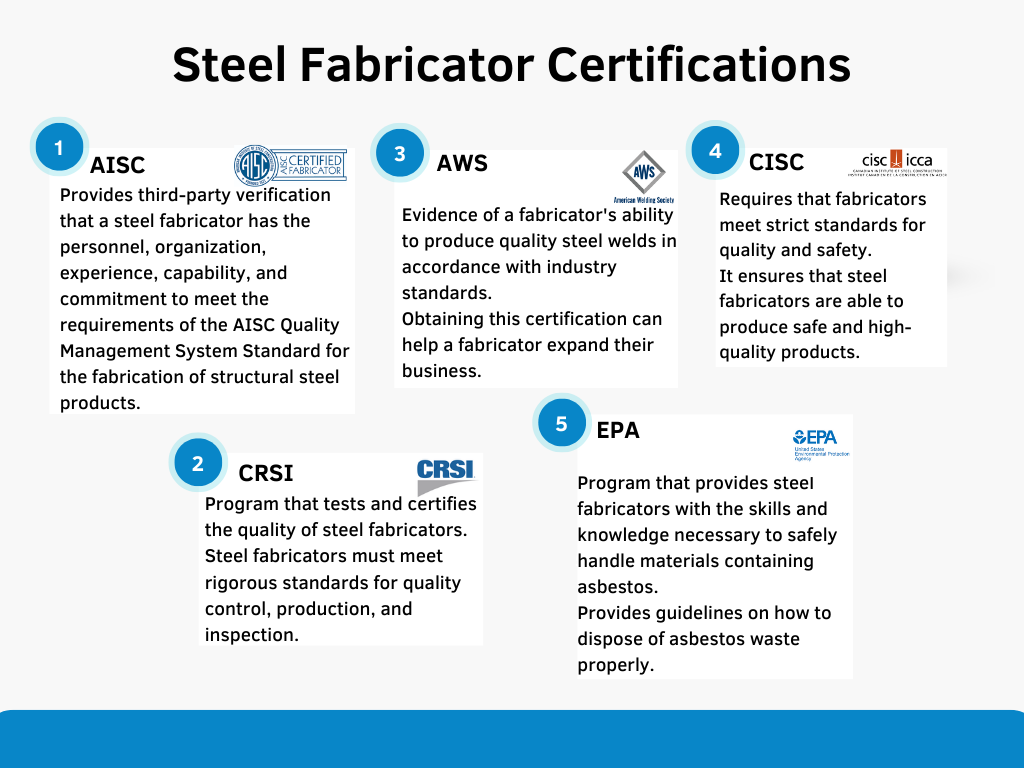

The AISC Certification Program is a voluntary program that provides third-party verification that a steel fabricator has the personnel, organization, experience, capability, and commitment to meet the requirements of the AISC Quality Management System Standard for the fabrication of structural steel products.

AISC Certification is recognized throughout the United States as the mark of a competent and trustworthy steel fabricator. If you are looking for a steel fabricator that can provide you with high-quality products and services, look for one that is AISC Certified.

2. CRSI (Concrete Reinforcing Steel Institute) Certification

The CRSI (Concrete Reinforcing Steel Institute) Certification is a program that tests and certifies the quality of steel fabricators. The certification is important because it assures the quality of the steel fabricator’s workmanship and materials.

In order to be certified, steel fabricators must meet rigorous standards for quality control, production, and inspection. The certification process helps to ensure that only the highest quality steel fabricators can participate in the program.

This certification is important for both the consumer and the industry because it helps ensure that only the best steel fabricators can provide their services.

3. AWS (American Welding Society) Certification

AWS certification is evidence of a fabricator’s ability to produce quality steel welds by industry standards. The certification process includes passing a written exam and welding test, which are administered by AWS-certified welding educators.

AWS certification is an important distinction for steel fabricators, demonstrating their commitment to quality and safety. Many companies will only work with fabricators who are AWS-certified, so obtaining this certification can help a fabricator expand their business.

In addition, being AWS-certified can help fabricators improve their welding skills and knowledge, making them more efficient and effective at their job.

Interested in exploring the welding career path further? Learn more in our article, ‘How To Become a Welder‘.”

4. CISC (Canadian Institute of Steel Construction) Steel Structures Certification

The Canadian Institute of Steel Construction (CISC) is a national organization that provides certification for steel fabricators. The CISC Steel Structures Certification requires that fabricators meet strict standards for quality and safety.

This certification is important because it ensures that steel fabricators are able to produce safe and high-quality products. In addition, the certification helps to promote uniformity across the steel fabrication industry, making it easier for customers to choose reputable and reliable fabricators.

5. EPA (Environmental Protection Agency) Safety Certification

EPA Safety Certification is a program that provides steel fabricators with the skills and knowledge necessary to safely handle materials containing asbestos. Asbestos is a naturally occurring mineral used in various industries for many years.

However, exposure to asbestos fibers can cause serious health problems, including lung cancer and mesothelioma. The EPA Safety Certification program helps ensure that steel fabricators are adequately trained to identify and safely remove asbestos-containing materials.

In addition, the certification program provides guidelines on how to dispose of asbestos waste properly. By completing the EPA Safety Certification program, steel fabricators can help protect themselves and their employees from the dangers of asbestos exposure.

6. ISO 45001 Certification

The ISO 45001, formally OSHA, is an agency that sets and enforces standards for workplace safety. One of the ways this certification ensures that workplaces are safe is by certifying businesses that meet specific safety standards.

For steel fabricators, ISO 45001 certification is important because it shows that the company takes safety seriously and is committed to protecting its employees.

By choosing to work with a certified steel fabrication company, you can be confident that you are working with a steel fabrication that cares about its employees’ safety and well-being.

7. ISO 3834 Certification

ISO 3834 certification is an internationally recognized quality standard for steel fabricators. The standard is divided into three parts, each covering a different aspect of quality assurance. Part 1 deals with quality management systems, Part 2 focuses on product conformity, and Part 3 covers welding personnel qualifications.

To achieve ISO 3834 certification, a steel fabricator must demonstrate that they have robust quality management systems in place and that their products meet the highest standards of quality. The certification is important for steel fabricators because it gives them a competitive advantage and helps to build customer confidence.

It also provides a framework for continuous improvement, ensuring that fabricators consistently meet the latest quality standards. Attaining ISO 3834 certification is a complex process, but it is an investment that can pay off in terms of increased sales and customer satisfaction.

8. ISO 9001 Certification

The ISO 9001 certification is an internationally recognized standard that specifies the requirements for quality management systems. It is important for steel fabricators to be ISO 9001 certified because it demonstrates their commitment to quality and customer satisfaction.

The certification shows that the company has a well-defined quality management system. This system helps ensure that all work is carried out consistently and controlled and that any problems are quickly identified and rectified.

Ultimately, the certification provides reassurance to customers that they will receive a high-quality product or service.

Book a 60-minute demo to see

how eziil mrp solution works for you

9. EN 1090 (Execution of Steel Structures and Aluminum Structures)

EN 1090 is a European standard for the fabrication and erection of steel and aluminum structures. The goal of the standard is to improve safety and quality control in the construction industry.

To become EN 1090 certified, fabricators must have their welding procedures and quality control systems audited by an independent body. The certification is important because it demonstrates that a fabricator can produce safe, high-quality products.

10. CE Marking

CE Marking is a mandatory conformity marking for certain products sold within the European Economic Area (EEA). The CE mark indicates that a product has been assessed by the fabricator or manufacturer and found to meet EU safety, health, and environmental protection requirements.

This assessment is known as conformity assessment. Conformity assessment is a procedure by which a body, such as notified bodies, assesses whether or not a product meets the requirements of the relevant EU directives.

The CE mark allows fabricators and manufacturers to freely circulate their products within the EEA without undergoing further conformity assessment procedures. The CE mark also assures consumers that a product meets their expectations in terms of safety and performance.

What is Structural Steel Fabrication?

Structural steel fabrication is a multifaceted process of cutting, bending, and assembling steel for the purpose of creating the final structural products. In the fabrication process of steel structures, several pieces of steel members of various forms are put together following engineering design drawings and assembled to form different structures of predefined shapes and sizes. The steel structural process is quite complex involving skilled manpower. Fabricated steel structures are found everywhere including in buildings, industrial equipment, tools, the construction industry, and various other final products.

However, note that structural steel fabrication doesn’t mean all the weldings that are performed for strengthening or repairing steel. Steel fabrication is a highly specialized skill requiring wide experience and understanding to convert raw steel components into final useful products satisfying the requirements of various codes and standards.

Conclusion

In summing up, the ISO 9001 certification stands as a beacon of quality assurance, illuminating the pathway to continual improvement and excellence for a steel fabricator. This ISO certification, underpinned by a robust quality management system, serves as an irreplaceable tool for companies aiming to align their business processes with international standards, ensuring the delivery of high-quality products and services.

ISO 9001 certified companies adhere to a rigorous framework of quality management that permeates every facet of their operations. This commitment to quality is echoed by top management, trickles down to human resources, and is embedded in all business processes. The ISO 9001 certification is not merely an accolade; it’s a commitment to a culture of quality that resonates throughout the organization, touching every department, every process, and every product or service offered.

Internal audits form a critical part of this commitment to quality. Regular internal audits ensure adherence to the standards outlined by the ISO 9001 certification and serve as a means to continually evaluate and improve performance. These audits play a pivotal role in the quality management systems, fostering a culture of continual improvement and enabling the organization to meet its business objectives more effectively.

The role of human resources in achieving and maintaining this ISO certification is crucial. Employees must be empowered and competent, capable of delivering high-quality products and services that meet the stringent standards of the ISO 9001 certification. Performance evaluation is a key part of this, serving as a tool to identify areas for improvement and enhance skills, further contributing to the goal of continual improvement.

Moreover, ISO certified companies demonstrate their unwavering commitment to legal compliance. They ensure that their operations, products, and services not only meet the high-quality standards outlined by the ISO 9001 certification but also adhere to all relevant legal requirements.

In conclusion, the ISO 9001 certification is more than an international standard; it’s a commitment to a culture of quality, efficiency, and continual improvement. From the top management to human resources, from business processes to products and services, every facet of the organization is geared towards meeting this standard. Regular internal audits, performance evaluations, and a commitment to legal compliance all contribute to this goal, underpinned by a robust quality management system. As such, the ISO 9001 certification stands as a testament to a steel fabricator’s dedication to quality, customer satisfaction, and continual improvement, serving as a valuable asset in the competitive landscape of the steel fabrication industry.

Choosing a steel fabrication company can be difficult, but keeping these certifications in mind, will help narrow down options and ultimately lead to the best decision.

Eziil is a leading provider of MRP software for custom metal fabrication. We help our clients to streamline their production processes, improve communication and collaboration between departments, and reduce costs.

Our team of experts is always on hand to provide support and advice, and we offer a free trial so that you can try our software before you buy it. If you’re looking for an MRP software solution to help your business run more efficiently, sign up today.