Are you a metal fabricator or a manufacturer struggling to learn about different sorts of steel? There are many types of steel, and each has unique properties that make it ideal for specific applications. This blog post will provide a detailed guide to the different sorts of steel, including their properties and applications. We’ll also discuss the advantages and disadvantages of each type of steel. Keep reading if you don’t want to end up using the wrong steel for your project.

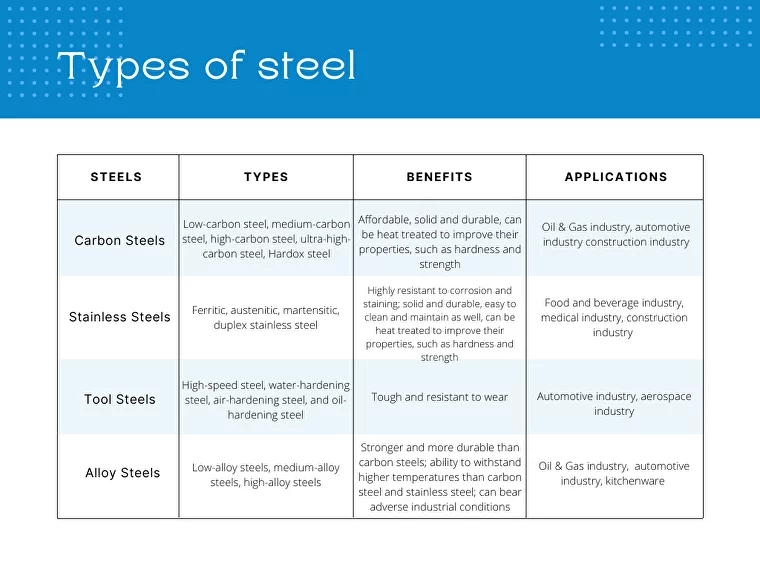

Steel is a metal alloy made up of iron and carbon; manufacturers have been using it for hundreds of years. It comes in many grades, classified according to its composition and mechanical properties. The four main types of steel are carbon steel, alloy steel, stainless steel, and tool steel. Let’s take a closer look at each one.

Not on EZIIL BOM yet?

Here’s a free online Steel Weight Calculator to help you nail kg/lb fast and avoid over-ordering, surprise freight-class up-charges, and “gotta-grab-a-bigger-forklift” emergencies.

What are the Different Types of Steel?

Do you fear buying or using the wrong type of steel for your project? Worry not; this guide will help you in choosing the right one for your project. Below are some of the most commonly used types of steel available in the market. Let’s have a quick look at all of them.

1. Carbon Steel

It is a type of steel with up to 2.1% carbon by weight. The different types of carbon steel include low-carbon steel, medium-carbon steel, high-carbon steel, and ultra-high-carbon steel. Hardox steel having low – medium carbon content also falls under this category and is an extensively used steel grade by metal fabricators.

Benefits

- Carbon steels are some of the most affordable sorts of steel on the market.

- They are also solid and durable, making them ideal for various applications.

- They can be heat treated to improve their properties, such as hardness and strength.

Applications

- In Oil & Gas, carbon steel is used for various applications, including Pipelines, Storage tanks, Pressure vessels, and Structural components. Carbon steel is an ideal material for these applications due to its durability and strength.

- Another major consumer of carbon steel is the automotive industry, where it is used to make a variety of parts, including body parts, frames, and engine components.

- Carbon steel is also commonly used in the building and construction industry, where it is used to make beams, columns, trusses, and other structural components.

2. Stainless Steels

Stainless steel is a type of steel that contains at least 11% chromium. Different types of stainless steel include ferritic, austenitic, martensitic, and duplex stainless steel.

Benefits

- Stainless steels are highly resistant to corrosion and staining.

- They are also solid and durable, making them ideal for a variety of applications.

- They are easy to clean and maintain as well.

- Stainless steels can be heat treated to improve their properties, such as hardness and strength.

Applications

- Stainless steels are commonly used in the food and beverage industry, where they are used to make kitchen utensils, food processing equipment, and storage tanks.

- They are also commonly used in the medical industry, where they are used to make surgical instruments, medical devices, and prosthetic implants.

- In the construction industry, stainless steel is used to make structural components, facade systems, and handrails.

3. Tool Steels

Tool steel is a type of steel that is designed for use in tools and dies. It is known for its hardness and resistance to wear. There are different types of tool steel, including high-speed steel, water-hardening steel, air-hardening steel, and oil-hardening steel.

Benefits

- Tool steels are tough and resistant to wear, making them ideal to make tools.

Applications

- Tool steels are commonly used in the automotive industry, where they are used to make parts such as engine blocks, cylinder heads, and transmission parts.

- They are also commonly used in the aerospace industry, where they are used to make parts such as turbine blades, aircraft frames, and landing gear.

4. Alloy Steels

To meet your diverse needs, alloy steel is formulated with different metals. The main types of alloy steels are low-alloy steels, medium-alloy steels, and high-alloy steels.

Benefits

- Alloy steels are stronger and more durable than carbon steels.

- They have the ability to withstand higher temperatures than carbon steel and stainless steel.

- They can bear adverse industrial conditions

Applications

- Pipelines used in the Oil & Gas industry are often made from alloy steels, as they can withstand the high pressures and temperatures involved in oil and gas transportation.

- Body panels used in the automotive industry are often made from alloy steel, as they can withstand the high stresses involved in transporting passengers and cargo.

- Kitchenware like toasters, pans, and pots are often made from alloy steels, as they can withstand the high temperatures involved in cooking.

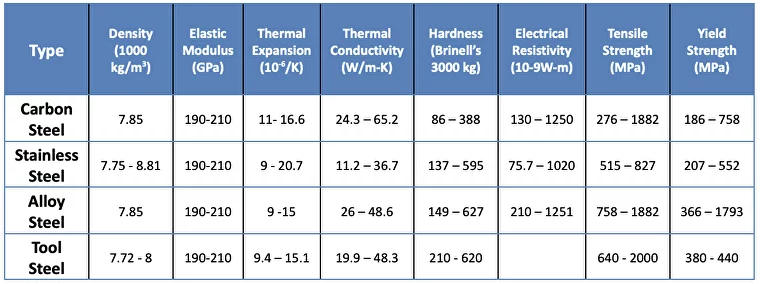

Technical Properties of Different Steel Grades

You can go through the technical properties of different steel grades in the table below.

The Most Suitable Types of Steel for Manufacturing and Structural Fabrication

There are many reasons why stainless steel is such a popular choice for manufacturing parts. First, it is robust and durable, which means it can withstand a lot of wear and tear. It is also resistant to corrosion and rust, meaning it will maintain its good looks for many years. Stainless steel is also easy to clean and sterilize, making it perfect for use in hygiene-critical environments such as hospitals and kitchens.

Finally, stainless steel has a very low thermal conductivity, making it ideal for use in applications where good heat resistance is required. In conclusion, there are many reasons why stainless steel is a popular choice for manufacturing parts.

Carbon steel, also known as structural steel, is a highly versatile material with many construction uses. It is most commonly used for the fabrication of steel beams and columns but can also be used to construct bridges, buildings, and other structures. Carbon steel is ideal for construction because it is strong and durable yet relatively lightweight.

Additionally, it is easy to work with and can be formed into a variety of shapes. As a result, carbon steel is one of the most popular materials used in construction today.

Book a 60-minute demo to see

how eziil mrp solution works for you

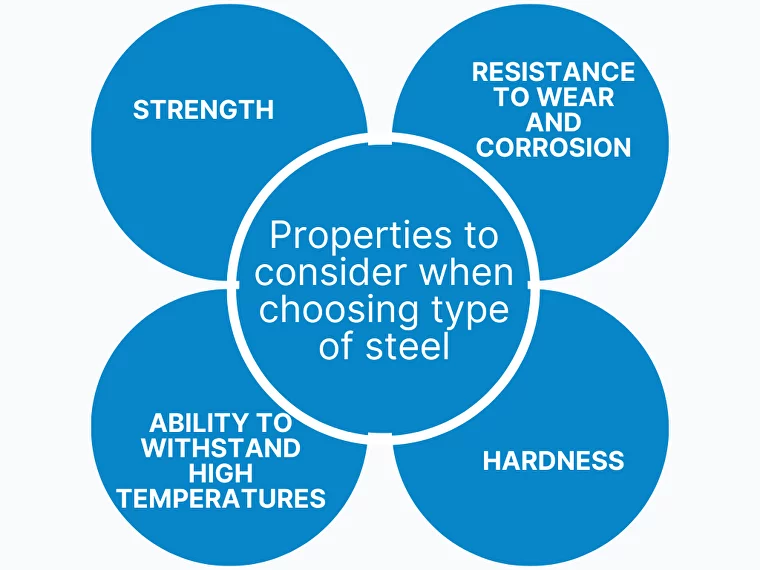

Choosing an Appropriate Steel Grade for your Project

Different sorts of steel are produced according to the properties required for their application. These properties include:

- Strength

- Hardness

- Resistance to wear and corrosion

- Ability to withstand high temperatures

As a result, a wide variety of steel grades are available on the market, each with its unique set of properties.

When choosing a steel grade for your project, it is vital to consider the application’s specific requirements. For example, stainless steel is often used in food processing and medical equipment due to its high corrosion resistance. Carbon steel is typically used for metal fabrication due to its high strength-to-weight ratio. And alloy steel is often used in aerospace and automotive applications because of its high strength and toughness.

By understanding the critical differences between these three types of steel, you can select the best option for your specific project needs.

Conclusion

The world of steel and its various types offers a vast array of possibilities for product designers and mechanical engineers alike. As we have explored the main types of steel used in manufacturing, it’s clear that the choice of steel type profoundly impacts the final product’s performance, durability, and aesthetic appeal.

Alloy steel, one of the most versatile steel types, is highly prized for its ability to combine with other elements to achieve specific properties. The advantages of steel alloys are vast, offering heat resistant capabilities and improving overall strength and toughness. In turn, these properties make alloy steel a suitable choice for demanding applications such as automotive parts, pipelines, and machine components.

Next, we have stainless steel grades, each offering unique properties that cater to specific applications. For example, austenitic stainless steels, known for their superior corrosion resistance and excellent formability, are commonly used in kitchen equipment, architectural facades, and chemical containers. Their magnetic properties are weaker than other steel types, which could be a disadvantage in applications where magnetism is crucial.

Tool steel, another essential steel type, is widely recognized for its hardness and resistance to abrasion. Heat treatment of tool steel enables it to resist deformation under high stress conditions, making it a preferred choice for tools and dies.

When it comes to steel materials with excellent welding capabilities and ductility, low carbon steel stands out. Its properties make it perfect for applications such as car body panels, metal chains, and wire products.

The heat resistant quality of steel is another significant aspect to consider. The ability of a steel type to resist degradation at high temperatures is crucial in industries such as aerospace, automotive, and power generation. Heat treatment processes play a vital role in enhancing this heat resistance, thereby improving the steel’s overall performance.

The subject of steel production also warrants our attention. Efficient and sustainable production methods are of paramount importance as they impact both the quality of the steel and its environmental footprint. Advances in steel production technology are continuously improving the industry, ensuring the availability of high-quality steel types for various applications.

Understanding the corrosion resistance of different steel types is essential, particularly in environments that are acidic or saline. Stainless steel grades, especially, are valued for their corrosion resistance, and their ability to resist stress corrosion cracking is a significant advantage in industries such as oil and gas, where equipment reliability is a must.

As we’ve explored, the selection of the right steel type, whether it be alloy steel, tool steel, or one of the many stainless steel grades, is a key consideration in product design and mechanical engineering. Understanding the heat treatment processes, the inherent heat resistant qualities of different steel types, and the magnetic properties and corrosion resistance of the various steel materials is integral to the successful application of steel in manufacturing.

The versatility and adaptability of steel make it an invaluable material in the modern world. Whether you’re looking for superior strength, excellent corrosion resistance, or superior heat resistance, there’s a type of steel that fits the bill. So, the next time you’re faced with a design or engineering challenge, remember the vast array of steel types available to you. They might just offer the perfect solution.

Final Verdict

So, there you have it – a detailed guide to the different sorts of steel and their respective benefits and applications. Hopefully, this article will help you better understand the various steel grades available on the market today and made choosing an appropriate grade for your project a little easier.

Eziil is an effective MRP software designed for the metal fabricators. The software offers several benefits such as purchase planning, inventory management, real-time data analytics, risk management, and many more. If you are in need of reliable MRP software after the discontinuity of Fabtrol than Eziil is the one you are looking for. You can reach out to our customer support to learn more about us. Thanks for reading!