Steel is available in many grades, shapes, and finishes, with the World Steel Association listing over 3,500 different steel grades, each with distinctive properties. All those various types mean that steel has seemingly endless applications in industries as diverse as automotive, military, construction, and manufacturing.

Changing steel’s chemical composition is one way to optimize it for specific applications, but it’s not the only way. Steel’s manufacturing process also significantly affects steel products, even though the specifications and grades might be similar or alike. One essential variance among steel products is the difference between hot-rolled and cold-rolled steel.

What is Rolling?

The metal forming process known as rolling uses a series of rollers to modify the shape, enhance uniformity, or improve the material’s mechanical properties. Rolled steel is classified into hot rolled steel and cold rolled steel, each with distinct characteristics making them appropriate for different applications.

The difference between hot rolled vs. cold rolled steel relates to the processing methods at the mill. For example, hot rolled steel involves rolling the steel at high temperatures. In contrast, cold rolled steel is processed in cold reduction mills where the material is cooled, followed by annealing to remove internal stresses or temper rolling to improve its tensile properties.

How is Hot Rolled Alloy Steel Processed?

Hot rolled steel is roll-pressed at over 1,700 degrees F, making it easier to form and leading to products that are easier to work with.

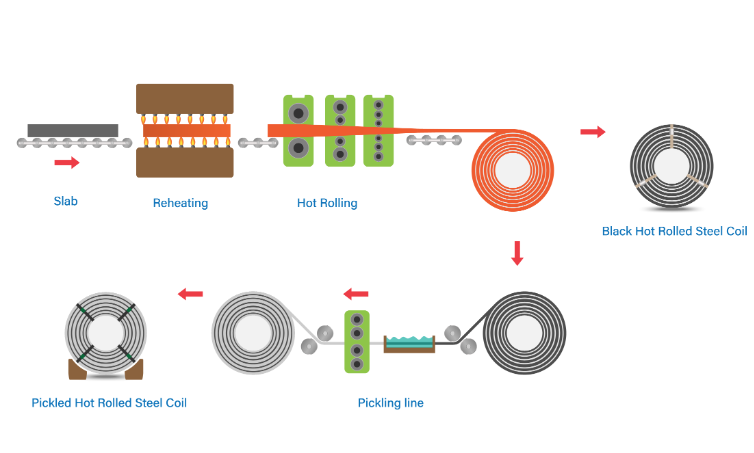

Manufacturers start the process with a large, rectangular metal piece called a billet. The billet is heated and sent for pre-processing, which entails flattening it, keeping it at a high temperature, and running it through a series of rollers for its finished dimensions. The extremely hot steel strands are pushed through the rollers at high speeds. The rolled steel is spun into a hot roll coil (HRCS steel) for hot rolled sheet steel and left to cool. For bars and plates, the materials are sectioned and packaged.

Because hot rolled steel is cooled and shrinks after processing, there is less control over its final shape, meaning it isn’t as suitable for precision applications. Instead, HRS steel is more likely to be used in applications where precise dimensions aren’t critical. Construction projects typically use HRS material.

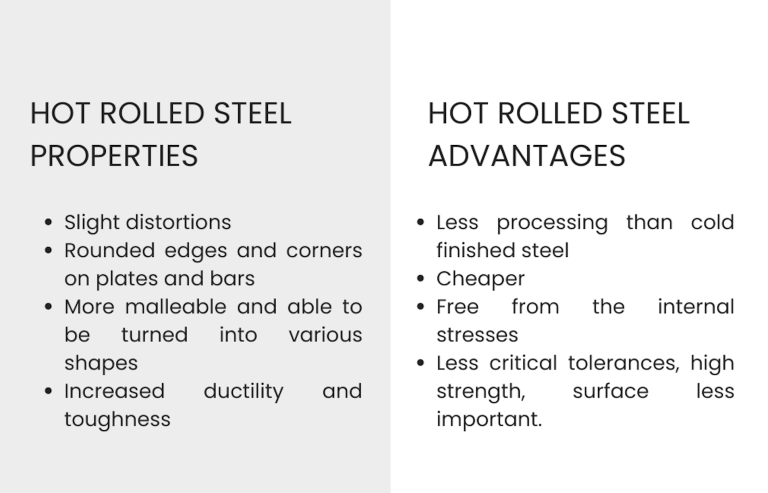

What are the Hot Rolled Steel Properties?

The following characteristics quickly identify hot rolled steel:

- Slight distortions, including a scaly finish

- Rounded edges and corners on plates and bars

- More malleable and able to be turned into various shapes

- Increased ductility and toughness

What are the Advantages of Hot Rolled Steel?

Hot rolled steel typically requires much less processing than cold finished steel, making it much cheaper. Since hot rolled steel can cool at room temperature, it’s free from the internal stresses arising from quenching or work-hardening processes.

Hot rolled steel is ideal when dimensional tolerances are less critical, material strength is required, and the surface finish isn’t a primary concern. In cases where the surface finish is essential, the scaling can be removed by grinding, sandblasting, or acid-bath pickling. After removing the scaling, the descaled steel surface offers a better surface for painting and other surface coatings.

What is Cold Rolled Steel?

Cold rolled steel is essentially hot rolled steel with extra processing. After the hot rolled steel has cooled, it is rolled again at room temperature for more precise dimensions and a better surface finish.

The term cold “rolled” steel typically describes a range of finishing processes, but it technically applies only to sheets that undergo compression between rollers. When referring to pulled steel, such as bars or tubes, “cold finishing” consists of cold drawing, turning, grinding, and polishing operations.

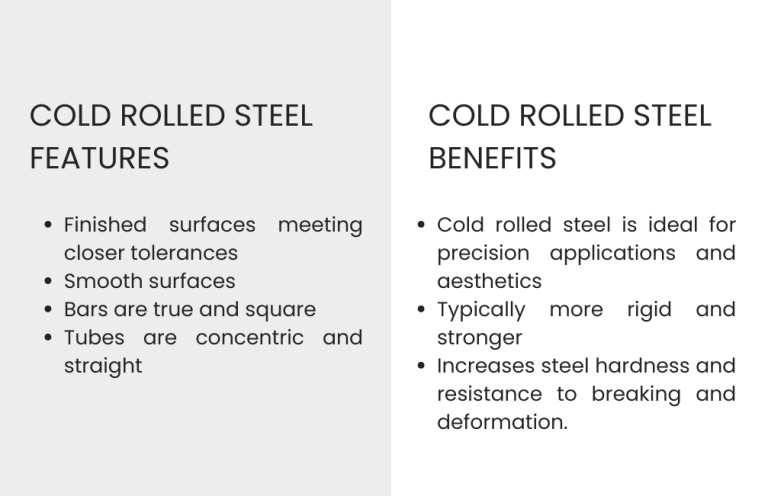

What are the Features of CRS Steel?

The following characteristics identify cold rolled steel:

- Finished surfaces meeting closer tolerances

- Smooth surfaces that are often oily to the touch

- Bars are true and square with well-defined edges and corners

- Tubes are concentric and straight

What are the Benefits of Cold Rolled Steel?

Because of their surface characteristics, cold rolled coils, bars, sheets, and tubes are preferred for technically precise applications or whenever aesthetics are essential. However, they come at a higher price because cold finishing requires additional processing.

Cold finished steel is typically more rigid and stronger than hot rolled steel. Since the metal is shaped at lower temperatures, the steel’s hardness, resistance against tension breaking, and resistance against deformation are all increased because of the work hardening.

However, these additional treatments can create internal stress that can cause warping if the steel is not stress-relieved before cutting, grinding, or welding.

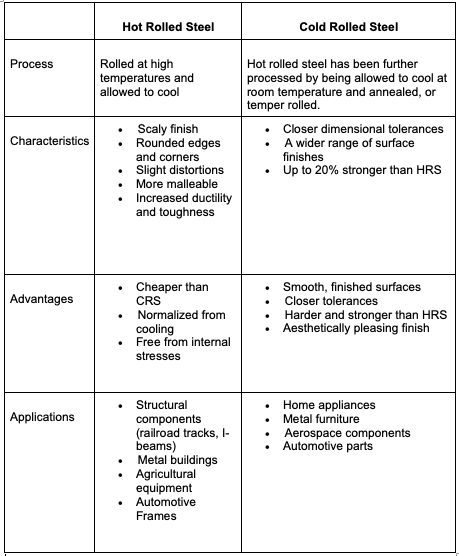

Hot Rolled Steel vs. Cold Rolled Steel

When choosing a rolled steel material for a project, it is crucial to consider the differences between the two steel types and how they affect their performance. For a side-by-side comparison of the two, check out the “Hot Rolled vs. Cold Drawn” table below:

The Bottom Line: Hot Rolled Steel vs. Cold Rolled Steel Strength Comparison

Hot Rolled (HR) and Cold Rolled (CR) steel methods shape the world of sheet metal fabrication. HR steel, ideal for large scale, structural applications, contrasts with CR steel, favored for precision and a polished finish in materials such as stainless steel. The choice between HR and CR steel can drastically affect a project’s outcome.

Cold rolled steel demonstrates up to 20% greater strength than hot rolled steel, making it more suitable for high-stress applications. However, the additional material strength and hardness produced by the cold rolling process come at a price: more significant internal stresses.

These stresses must be relieved before the material can be processed, or the cold finished steel part or product will likely warp.

Even with its higher cost, cold rolled steel has many qualities, making it the superior choice!