This guide is an invaluable resource for understanding the nuances of steel fabrication, from quality standards to bespoke services.

It’s ideal for industry professionals, businesses in search of reliable steel contractors, or individuals needing bespoke solutions from top metal manufacturers. This guide offers easy-to-understand insights, helping you choose the right steel manufacturer or fabrication company for your unique project needs.

2. Cook Fabrications

Year Founded:

1979

Cook Fabrications possesses expertise in delivering structural steelwork services across a diverse array of industries within the public and private sectors of the South East region of the UK. The company can manufacture virtually any steel fabrication to precise customer specifications and drawings.

The contemporary manufacturing facility boasts an extensive array of structural steel and metalwork equipment, which includes CNC guillotines, brake presses, plasma cutters, and drilling/saw lines.

This comprehensive machinery inventory ensures the capacity to cater to diverse metalwork requirements, aligning perfectly with customer specifications.

Cook Fabrications also maintains trained teams of skilled steel erectors who are adept at installing anything from staircases to complete structural buildings.

Leveraging the advanced TEKLA Software, the company is equipped to internally generate 3D fabrication drawings using architect-supplied plans or engineering files. Leveraging the expertise of their experienced professionals, Cook Fabrications possesses the capability to provide valuable suggestions for product improvement, directing clients towards the most efficient and cost-effective design strategies.

Cook Fabricators proudly hold certifications in BS EN ISO 3834-3:2005 and ISO 9001, underscoring their commitment to excellence.

Check out the introduction video below to get a closer look at Cook Fabrications:

1. Billington Structures Ltd

Year Founded:

1947

Key Products/Services:

Design, fabrication, and construction of steel structures (15,000 tonnes), including industrial buildings, commercial buildings, bridges, and bespoke structures.

Billington Structures stands as an exemplar within the UK’s structural steelwork sector, boasting over 75 years of innovation, quality, and precision in every project they undertake. Their secret to success is a meticulously refined process that ensures flawless execution from design to installation, regardless of a project’s scale.

Their team, with deep expertise, ensures smooth, efficient, and timely deliveries across all phases, including commercial aspects, design, project management, manufacturing, and installation.

Billington Structures’ innovative projects and exemplary craftsmanship have been recognized with prestigious awards, showcasing their leadership and excellence in the structural steelwork industry.

For example, in 2021, they were honored at the UK Tekla Awards, winning in the Sports & Recreation category for their outstanding work on the Sandwell Aquatics Centre.

The year 2020 was particularly notable for Billington Structures; they received a commendation at the Structural Steel Design Awards for their work on the Centre Building at the London School of Economics. Additionally, their project, The Wave in Coventry, was a finalist at the same awards.

Their commitment to maintaining the highest standards is evidenced by their impressive array of accreditations. Notably, Billington Structures has earned the prestigious Cyber Essentials Plus certification, reflecting its dedication to cybersecurity and data protection.

Moreover, they hold ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety management standards, and much more.

Beyond their structural steelwork projects, Billington Structures is deeply committed to community and charitable initiatives, embodying their belief in the importance of building stronger communities alongside structures.

2. STEELO Structural Steel Fabricators

Year Founded:

2009

Key Products/Services:

Structural steel services from simple connections to entire building frames.

Originally established as a one-person venture, Steelo (formerly known as Polsteel) emerged with a primary focus on its customers. The driving force behind its success, Michael Krajewski, graduated from Warsaw University of Technology and became a self-made entrepreneur, driven by a clear vision and unwavering determination.

Steelo’s initial base was a modest unit in Isleworth, Middlesex. During its inception, the production process was entirely manual. However, in 2015, the introduction of drilling and cutting machines marked a significant step towards automation, with Steelo’s trajectory aiming for full automation shortly.

Currently, the company’s steelwork fabrication occurs within a semi-automated, 12,000-square feet facility near Heathrow.

Steelo maintains an ongoing commitment to enhancing productivity and efficiency, ensuring that each project is executed promptly and to the highest standards. Their mission is to deliver value at competitive prices without compromising quality.

Through the adoption of improved scheduling and production control practices, Steelo aims to minimize lead times.

The sales, design, production, and logistics teams comprise a group of talented and dedicated individuals who ardently uphold the company’s values. Serving as the cornerstone of the enterprise, they collectively contribute to Steelo’s success.

Check out the video below to discover why Michael Krajewski started Steelo:

3. Cook Fabrications

Year Founded:

1979

Cook Fabrications possesses expertise in delivering structural steelwork services across a diverse array of industries within the public and private sectors of the South East region of the UK. The company can manufacture virtually any steel fabrication to precise customer specifications and drawings.

The contemporary manufacturing facility boasts an extensive array of structural steel and metalwork equipment, which includes CNC guillotines, brake presses, plasma cutters, and drilling/saw lines.

This comprehensive machinery inventory ensures the capacity to cater to diverse metalwork requirements, aligning perfectly with customer specifications.

Cook Fabrications also maintains trained teams of skilled steel erectors who are adept at installing anything from staircases to complete structural buildings.

Leveraging the advanced TEKLA Software, the company is equipped to internally generate 3D fabrication drawings using architect-supplied plans or engineering files. Leveraging the expertise of their experienced professionals, Cook Fabrications possesses the capability to provide valuable suggestions for product improvement, directing clients towards the most efficient and cost-effective design strategies.

Cook Fabricators proudly hold certifications in BS EN ISO 3834-3:2005 and ISO 9001, underscoring their commitment to excellence.

Check out the introduction video below to get a closer look at Cook Fabrications:

4. Birmingham Fabrications

Year Founded:

2017

Key Products/Services:

Steel fabrication, aluminum fabrication, and structural steelworks (steel frame structures, steel staircases, balustrades, mezzanine floors).

Welding, paint, shot blasting, transport, workshop

Birmingham Fabrications boasts an extensive background of over 30 years in the field. Their expertise is centered around steel fabrication and installation across the entire UK.

The company provides a comprehensive suite of services all within a single framework – from initial concept to final installation, They possess the capability to ensure a holistic approach.

The scope of fabrication services offered by Birmingham Fabrications is diverse and includes, but is not limited to, steel frame structures, steel staircases, balustrades, mezzanine floors, and various other offerings. The Factory Production Control is based on the requirements of BS EN 1090-1 & 2, and ISO 3834-3.

Beyond fabrication, Birmingham Fabrications also extends an array of supplementary services.

This includes in-house shot-blasting, painting, and transport solutions.

5. PMS Fabrications

Year Founded:

2000

Key Products/Services:

Detail, manufacture, and erection of structural steelwork and cladding, all in- house with full site management (structural steel, bespoke architectural steelwork, cladding, installation, and crane hire)

Situated in Carlisle, Cumbria, PMS Fabrications has solidified its standing as a pioneering force in the realm of steel fabrication.

The company takes immense pride in presenting a wide spectrum of top-tier steel fabrication services to its clients. Operating as both fabricators and installers of structural steel and architectural steel, they possess the capacity to address all project prerequisites.

Moreover, their expertise extends to adopting providers of cladding systems and crane hire services.

With an inception spanning over 35 years, the highly skilled team at PMS Fabrications initially burgeoned from the confines of their Managing Director’s home garage.

Presently, they boast a workforce of 50 individuals, each contributing to the enterprise’s triumph with their varied skill sets. The company’s contemporary workshop facilities enable them to undertake structural steel projects of up to 50 tonnes per week.

The company is accredited with FPC-EXC-3 – BS EN 1090-1 and WQMS-C – BS EN ISO 3834.

Through fostering close-knit collaborations with clients entrenched in both the construction and industrial sectors, as well as a multitude of private clients, PMS Fabrications has solidified its dedication to delivering a multitude of compelling steel fabrication ventures in the times ahead.

Book a 60-minute demo to see

how eziil mrp solution works for you

6. ADEY Steel

Year Founded:

1925

Key Products/Services:

Design, detailing, project management, manufacture, supply and installation services

Adey Steel holds a prominent position among the leading steel fabricators in the UK.

Operating from their factory headquarters located in the Midlands, they provide steadfast support to clients spanning the Rail, Energy, Infrastructure, and Engineering sectors.

The enduring values established by their founder, Harry Adey, in 1925 remain deeply embedded within their business operations to this day.

As a family-owned entity, they take immense pride in their commitment to quality.

Adey Steel has garnered a reputation for effectively executing steel projects and meeting the precise requirements of its clients while upholding the highest industry standards for workforce safety.

The range of services they provide encompasses design and detailing, site surveying, project management, fabrication, inspection, delivery, and installation.

ADEY Steel certifications include PQAL ISO 14001:2015, CHAS Health and Safety, SMAS Workforce, NHSS20, ISO 14001, ISO 3834 TUV NORD, and BSEN 3834.

Get an inside look at Adey Steel with the introductory video below:

7. Hartwell Manufacturing and Mechanical Services

Year Founded:

1974

Key Products/Services:

High-quality fabrication and mechanical engineering services (heavy steel and general fabrications, material handling plant, vessels and tanks, chimneys and flues, installation and site services).

Drawing upon their wealth of knowledge and extensive experience in heavy steel fabrication, Hartwell Manufacturing stands poised to fulfill your precise requirements.

With a track record encompassing diverse industries, they assert that their heavy steel fabrication expertise ranks among the foremost available.

Operated as a privately owned enterprise, Hartwell Manufacturing has been rendering machining and fabrication services since 1974.

For more than three decades, they have meticulously built an outstanding reputation. This enduring history has facilitated the establishment of strong relationships with numerous clients who have recurrently sought their services.

A plethora of the heavy fabrications they offer are well-suited for a diverse spectrum of industrial establishments. These include handrails, gates, barriers, chequer plate flooring, ladders, and an assortment of other items and components of structural apparatus, all meticulously crafted to precise specifications.

Their proficiency extends to fabricating steel items that can weigh up to 100 tonnes.

This substantial capacity has enabled them to collaborate with organizations based at some of the largest sites throughout the UK.

8. MJ Ellis Manufacturing

Year Founded:

1979

Key Products/Services:

Steel fabrication and installation experts (free site surveys, architectural metal work, stainless steel metalwork, structural steelwork, laser cutting, profile cutting, steel supply, customised staircases and much more).

Inaugurated in 1979, MJ Ellis Manufacturing has emerged as a respected entity offering metal fabrication services across Hampshire, Dorset, and adjoining regions. Their extensive array of services encompasses design, and they incorporate advanced CAD, 3D projections, and structural calculations as integral components of their offerings.

Comprising a comprehensive scope, their services span free site surveys, architectural metalwork, stainless steel metalwork, structural steelwork, laser cutting, profile cutting, steel supply, customised staircases, and a variety of other provisions.

Within their range of services, they offer a variety of fabrication options, encompassing general steel fabrication, structural engineering, tailor-made staircases, and steel buildings. At M J Ellis, a strong commitment to quality is evident.

The company has dedicated several years to the ongoing enhancement of its quality systems, with the primary goal of surpassing industry benchmarks.

Since 2014, M J Ellis has proudly maintained accreditation to BS EN1090. This steadfast commitment extends to the production of all their goods, which are consequently subject to UKCA marking, accompanied by comprehensive certification and meticulous traceability records for every project.

In 2019, the company achieved ISO 9001 certification, a milestone that remains unbroken.

This achievement has empowered M J Ellis to collaborate with an array of prominent clients who demand exacting quality standards throughout the entirety of the organization.

9. LYCETT Fabrications

Year Founded:

1994

Key Products/Services:

Material processing, fabrication, welding, NDT, machine/boring/driling, flamecutting, chamfering

Situated at the heart of the industrial Midlands, LYCETT Fabricators continues the legacy of the region by consistently delivering engineering excellence across all aspects of their operations.

Their steel fabrication hub in Tamworth takes advantage of the favourable local transportation links, enabling the delivery of finished medium and heavy steel fabrication products to various locations throughout the UK, precisely when they are needed.

With a workforce comprising 20 well-trained and proficient employees, backed by a substantial 26,000 square feet production area, they possess the essential resources, space, and expertise to successfully execute projects within allocated budgets and timelines.

Their Tamworth facility offers an extensive range of in-house steel fabrication services, encompassing welding, flame cutting, sawing, machining, jig-boring, shot blasting, and finishing. This comprehensive capability empowers them to transform provided schematics into finished fabrications that precisely align with client specifications.

Continuous investments in enhancing their steel fabrication capabilities enable them to offer a holistic in-house service, ensuring consistent quality control and material traceability throughout the production processes, all accredited to the ISO 9001:2015 standard.

Catering to a diverse range of demanding sectors, they offer a complete suite of services dedicated to supplying customised, precision-crafted medium and heavy gauge fabrications.

Their client base spans various industries, including agriculture, environmental management, waste management, transportation, mining, architecture, and machinery.

Want to know what Lycett Fabrications does? See the details in the video below:

10. Haley Engineering

Year Founded:

1986

Key Products/Services:

Supply & erection of steel frames ranging from 100T to 1,500T (steelwork, fabrication and erection, metal decking and edge protection)

William Haley Engineering, established in 1986, operates as part of the Haley Group, a family-owned enterprise specializing in construction, employing a workforce of 160 individuals, thus ranking among the largest steelwork fabricators in England. This expansive capacity positions them to undertake projects nationwide.

Situated conveniently at junction 22 of the M5, William Haley Engineering boasts a combined facility spanning 5,000 square meters within a one-hectare site.

In close proximity, FLI, located near junction 12, occupies a facility encompassing 3,600 square meters on a 0.8-hectare plot.

William Haley Engineering possesses the capability to manufacture up to 10,000 tonnes of steel annually and has actively contributed to some of the United Kingdom’s most significant recent steel initiatives.

With a robust commitment to health and safety, an exemplary track record for quality, and a team of dedicated experts, they stand as the ideal choice for your forthcoming project, ensuring safe and accurate delivery from the outset.

The products of William Haley Engineering conform rigorously to all pertinent regulations derived from European Directives. Their compliance is maintained at the highest standards, with certifications including CE BS EN 1090-1 FPC Execution Class 4 and CE BS EN 1090-2 WC Execution Class 4, enabling them to operate on critical sites, such as those in the nuclear sector.

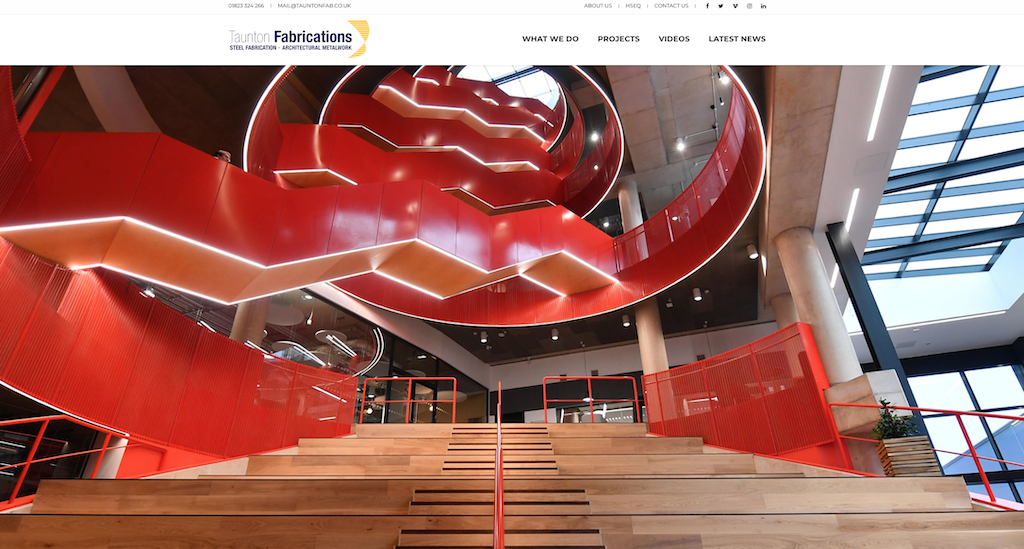

11. Taunton Fabrications Ltd

Year Founded:

1992

Key Products/Services:

Specialising in steel fabrication and architectural metalwork (staircases, helical stairs, stainless steel balustrades, glass canopies, bridges and walkways)

Taunton Fabrications, a leading supplier of architectural metalwork in the South of England, excels in transforming metal into bespoke features like balconies, staircases, and structural steelwork. With more than 25 years of commitment to excellence, this company is a pillar in the construction sector, renowned for its quality and innovative approaches.

Their philosophy centers on continuous improvement, with contributions from each team member driving projects to exceed client expectations. With accreditations like ISO9001:2015 and BS EN 1090-1, Taunton Fabrications demonstrates a steadfast commitment to quality and sustainability.

They pride themselves on robust partnerships with some of the UK’s top construction companies and architects, engaging early in the design process to ensure cost efficiency and precision. Equipped with modern facilities, their skilled team ensures that from design through installation, every detail is handled with utmost care, adhering to the highest safety standards.

Discover how Taunton Fabrications is not just crafting structures but redefining architectural possibilities, making every project a landmark.

For more insights into their projects, you can watch the video below:

12. Steelgram Fabrications

Year Founded:

2008

Key Products/Services:

Design manufacture and installation of a range of structural and secondary steelwork (site visit, design, manufacture, installation)

Established in 2008, Steelgram Fabrications Ltd was founded to cater to the requirements of Architects, Engineers, and Main Contractors seeking a specialized partner in Structural Steelwork and Metalwork.

The company offers comprehensive services, spanning from the design phase to project completion.

The directors of the company are actively involved in the operations, drawing from a collective experience of over 50 years in steelwork fabrication.

Headquartered in Sheffield, Steelgram Fabrications Ltd’s reach extends across the entire United Kingdom, providing structural steel and fabrication services.

Services of Steelgram include site visits, design, manufacture, and installation. Steelgram Fabrications Ltd has achieved CE execution Class 2, CHAS Premium Plus, Construction Line Gold, and Acclaim Accreditation.

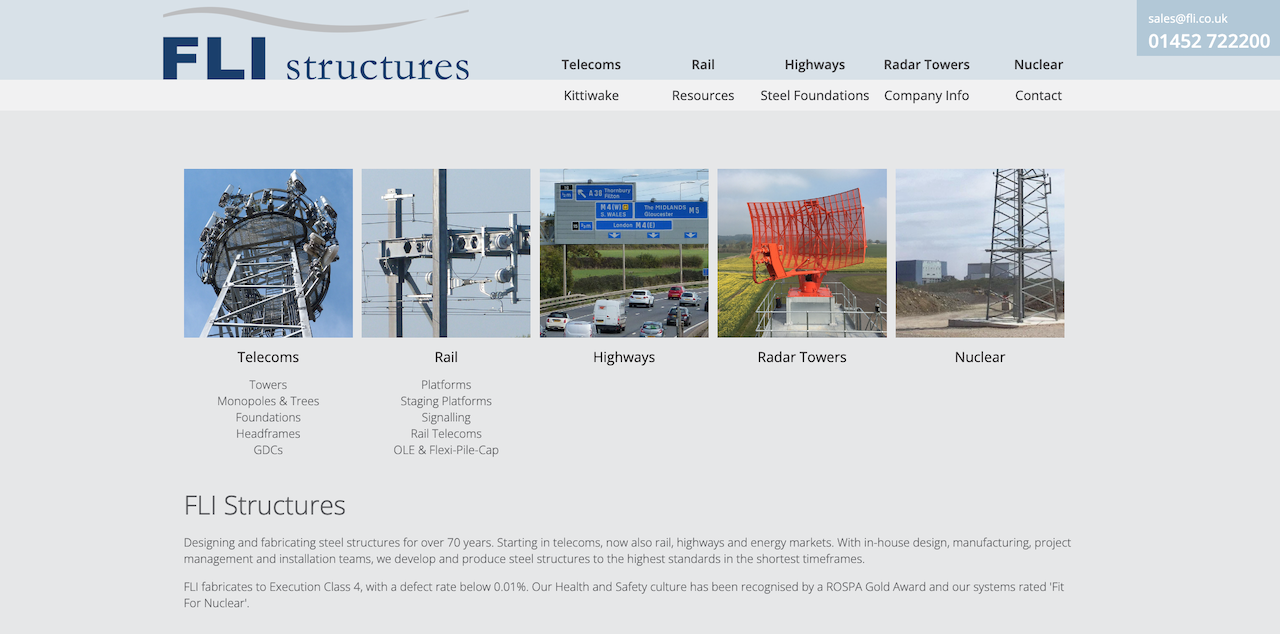

13. FLI Structures

Year Founded:

1954

Key Products/Services:

Develop and produce steel structures to the highest standards in the shortest timeframes

With a history spanning over 70 years, they have been actively engaged in the design and fabrication of steel structures. Their origins lie in the telecommunications sector, which has expanded to encompass rail, highways, and the energy markets.

Equipped with in-house design, manufacturing, project management, and installation teams, they remain committed to developing and producing high-quality steel structures within remarkably short timeframes.

FLI Structures also uses our Eziil software for better metal fabrication.

FLI’s fabrication standards adhere to Execution Class 4, with a notably low defect rate of less than 0.01%. Their dedication to Health and Safety has earned them a ROSPA Gold Award, and their systems have received a ‘Fit For Nuclear’ rating.

Operating across various sectors, including those witnessing advancements in sustainability, holds significance for them. Notably, in Control Period 6, Network Rail prioritizes ‘sustainability Requirements,’ and rail remains a key market for FLI.

Embracing sustainability considerations is no longer a discretionary effort for the supply chain.

Recognizing the efforts invested by their Quality, Health, Safety, and Environment (QHSE) team in recent years—enhancing monitoring precision and scope and aligning sustainability progress with quality standards—will undoubtedly assume an increasingly pivotal role in enhancing their market value.

14. SH Structures

Year Founded:

1992

Key Products/Services:

Design, supply, manufacture and install complex steel structures

SH Structures specializes in the design, supply, manufacturing, and installation of intricate steel structures. Although structural steelwork remains at the heart of their operations, they also extend their services to a diverse array of materials that frequently interact closely with their structures.

This inclusive strategy allows them to present clients with a comprehensive service package. Their commitment to their craft is evident, and they eagerly embrace the challenges that come their way.

Embracing a collaborative philosophy in construction, they ardently advocate for early engagement with specialist contractors, believing it to be instrumental in fostering successful outcomes.

SH Structures holds the prestigious accreditation of Execution Class 4, which enables them to meet the most demanding of specifications with ease.

Their Quality Management System (QMS) is accredited to ISO 9001:2008, signifying their commitment to maintaining high-quality standards. Moreover, their Welding Quality Management System (WQMS) is accredited to BS EN 3834 part 2 and aligns with the requirements of the EWF and IIW.

Additionally, their Factory Production Control (FPC) is accredited to BS EN 1090-2009, specifically Execution Class 4 to BS EN 1090-2:2008 standards.

SH Structures also boasts accreditation under the Highways Sector Scheme HSS20, further affirming their dedication to quality and compliance in their field.

15. Canterbury Steel

Year Founded:

2001

Key Products/Services:

Assistance for a large variety of steel engineering and supply services.

With over 20 years of experience in the trade, Canterbury Steel has developed a first-class service in all areas of steel engineering, fabrication, and supply, to enhance the quality and efficiency of construction projects. From installing steel beams and columns to erecting steel canopies and sheet metal work, Canterbury Steel is available to manage all requirements.

The professional services offered by Canterbury Steel cover a wide range of structural steel fabrications, including hollow sections, channels, and tubes, extending to steel assembly from planning to completion.

Whether one requires domestic or commercial steel fabrication or specialist steelwork in the Canterbury area, Canterbury Steel’s steel engineering and supply can be relied upon to ensure that construction work is as efficient as possible.

The engineering services encompass stainless steel fabrications, steel assembly services, steel fabrications, and structural steelwork.

How to choose the best fabricator in the UK?

When embarking on a construction project in the UK that involves steel structures, selecting the right steel fabricator is crucial for the success and efficiency of the endeavor. With the myriad of options available, it’s essential to consider a range of factors to ensure that the chosen fabricator aligns with the project’s requirements and goals.

Certifications: Ensuring Quality and Compliance

Certifications play a pivotal role in assessing the credibility and competence of a steel fabricator. In the UK, reputable fabricators hold certifications from recognised bodies such as the British Constructional Steelwork Association (BCSA), the Steel Construction Certification Scheme (SCCS), EN1090-1:2009 CE Execution Class 1, 2, 3, 4, and ISO 45001 Certification. These certifications are indicative of the fabricator’s adherence to industry standards, quality control processes, and commitment to safety.

Experience: A Testament to Expertise

Established fabricators often possess the expertise and knowledge gained from over thirty years of successfully delivering projects. Steel fabrication companies in the UK are involved in a wide range of projects across various industries. Their expertise spans from structural and architectural projects to industrial and commercial applications. Here are some of the types of projects that steel fabrication companies in the UK commonly undertake: Structural buildings and infrastructure, Architectural features, Industrial equipment and machinery, Energy utilities, Infrastructure and transportation, Renewable energy projects, and Interior design elements.

Location: Balancing Proximity and Costs

The geographical location of a steel fabricator is another crucial factor to consider. Certain cities and regions in the UK are hubs for steel fabrication activities. London, Manchester, Birmingham, and Glasgow are among the cities with a significant presence of fabricators. Fabricators nearby can streamline logistics and reduce transportation costs. Furthermore, if the project’s tender encompasses site work, involving the fabricator in the process can lead to more accurate cost estimates and efficient project execution.

Project Specialization and Handling Capability

Steel fabrication companies in the UK frequently focus on specific categories of projects to highlight their distinct abilities and areas of expertise. These project categories encompass Mezzanine Floors, Access Platforms, Balustrades, Steel Canopies, Secondary Steelwork, Structural Steelwork, Steel Staircases, and Portal Frames.

To evaluate their historical track record, examine the range of projects they have successfully executed, as well as their operational capacity. The majority of these firms are equipped to manage projects spanning from 5 tonnes to 500 tonnes. Most of the fabricators have a maximum capacity of lifting 100-tonne steel.

When a company takes on a larger project, it often requires heightened expertise in project planning and the ability to negotiate favorable steel prices through increased purchasing leverage. However, having its engineers and an in-house design department generally leads to higher overhead costs, which can, in turn, affect the pricing structure for smaller projects.

Stages of Work: From Fabrication to Installation

The range of services provided by a steel fabricator plays a pivotal role in customers’ selection process. In the UK, certain fabricators solely provide fabrication services, whereas others expand their role to encompass design and installation. A majority of fabricators handle both design and installation, offering advantages like efficient communication, diminished project coordination complexities, and an all-inclusive solution from a singular source.

Conclusion

In conclusion, our review of the UK’s top 15 steel fabrication companies in 2024 highlights the diverse capabilities and exceptional standards maintained by these industry leaders. From bespoke structural steel fabricators to versatile steel manufacturers, each company has demonstrated a commitment to excellence, innovation, and customer satisfaction. Whether you’re a steel contractor in search of a reliable fabrication company, a business seeking skilled metal manufacturers, or an individual with particular project requirements, these steel fabricators provide exceptional expertise and high-quality services.

As you navigate the dynamic world of metal fabrication, remember that the right partner can significantly impact the success of your projects. The fabricators listed in this guide not only meet but often exceed industry standards, ensuring that your needs are met with precision and professionalism. By choosing from these top-rated fabrication companies, you are not just investing in their services but also in the assurance that your project is in capable hands.

We hope this guide serves as your go-to resource for selecting the best metal fabricator to fulfill your unique needs. With the insights and information provided, you are well-prepared to make an informed decision, confidently partnering with a fabrication company that matches your project’s scale, complexity, and specific needs. Remember, in the world of steel fabrication, the success of your project is greatly influenced by the strength of your partnerships. Choose wisely!