You might not be familiar with the term “steel detailing.” After all, it’s a specialized area of structural drafting that few would encounter in their line of work. However, if you have ever been involved in creating a fabricated steel structure, you will likely understand the steel detailing process and the responsibilities of a steel detailer.

Whether you need an introduction or a refresher on steel detailing, the following should provide you with the basics and a bit more on this fascinating and critical work of creating structural steel drawings.

What is Steel Detailing?

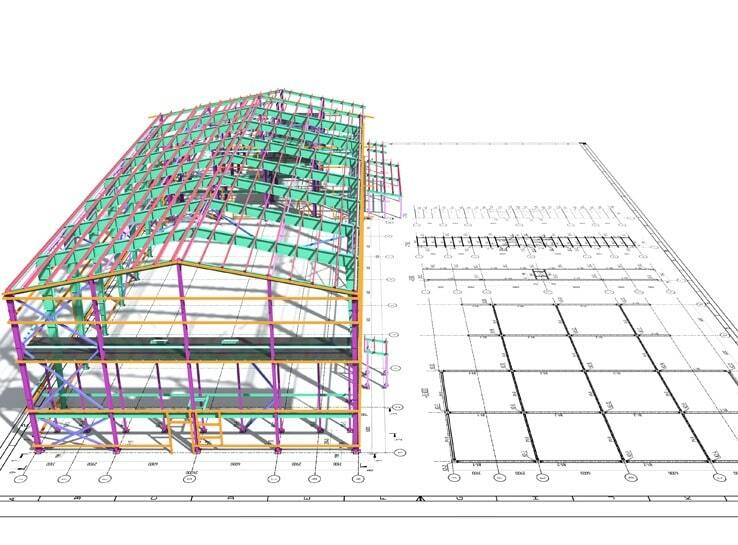

Image credit: https://astcad.com.au

Steel detailing companies produce structural steel drawings for fabricators and erectors.

These plans inform the steel fabrication shop of the dimensions and requirements of individual pieces.

They also instruct the fabricators on welding, installing, and erecting the steel framework on the job site.

Steel Detailing involves the development of comprehensive drawings for fabricators and contractors.

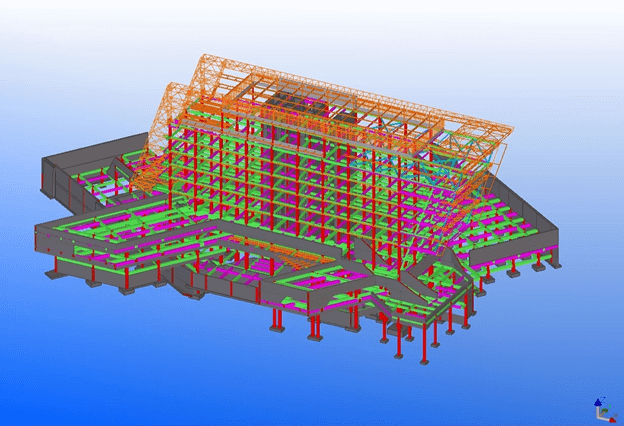

Image credit: https://astcad.com.au

Why is Structural Steel Detailing Important?

Steel details are part of the Building Information Modeling (BIM) process, where metal building detailing is organized in one model. BIM typically revolves around the 3D construction model. Still, it can also refer to the project’s budget, maintenance, materials, deadlines, positions, revisions, and anything significant for engineers, technical fabricators, and construction workers.

In effect, steel detailing means communicating project requirements in a way that directs the manufacturing and installation of the components required under the steel fabricator’s range of work.

There is no room for error when detailing for steel construction. Steel cut to the incorrect length or welded in the wrong place could result in costly field repairs. Even something innocuous like holes drilled in the wrong size or location can cost hundreds or thousands of dollars in additional labor and materials, not to mention expensive schedule delays.

What is a Steel Detailer?

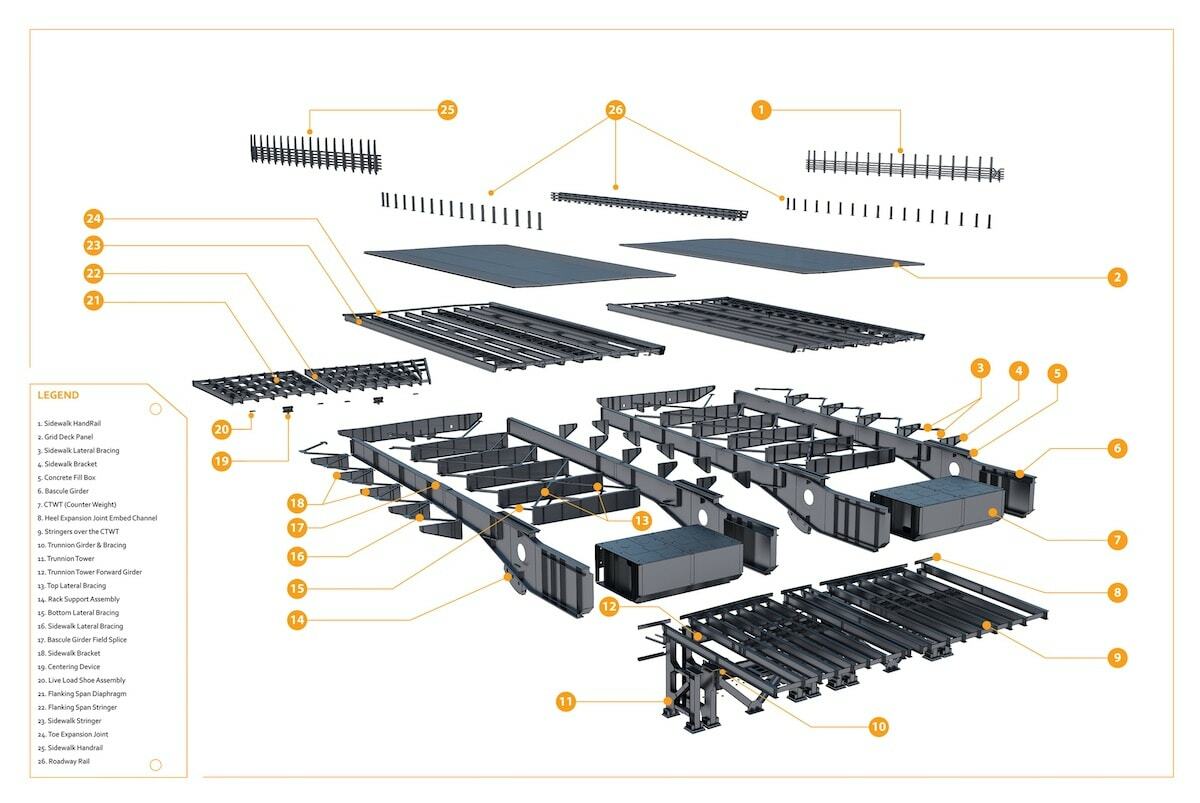

A steel detailer interprets architectural and structural engineering drawings to understand the design intent of a building better. They then provide detailed designs for the manufacture and erection of the columns, beams, braces, trusses, stairways, handrails, and joists comprising large steel structures, including buildings, bridges, plants, and stadiums.

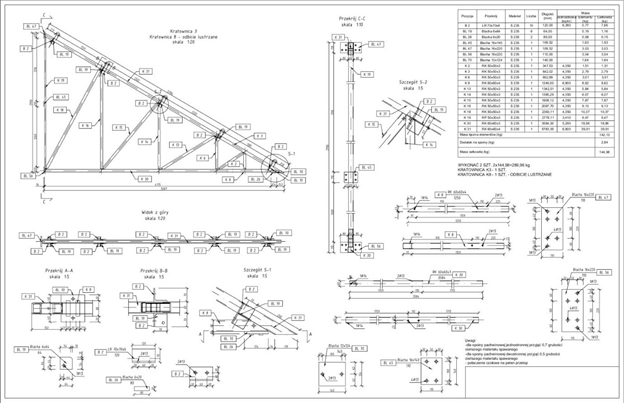

The structural steel detailer creates the shop and erection drawings required to build the steel structure. In the past, these drawings were produced using manual drafting methods (pencils, paper, drafting tools, and table). Today, detailers use computer-aided design (CAD), such as Autodesk Advance Steel and Tekla Structures, to create drawings and software for steel detailing.

See the samples below (image credits: https://blog.maestrosteeldetailing.com):

Steel detailing also includes other important stages, such as reinforcing steel detailing, anchor setting plans, steel design, connectivity diagrams, and the creation of a Bill of Materials (BoM).

Samples of steel detailing process.

Steel detailing also includes other important stages, such as reinforcing steel detailing, anchor setting plans, steel design, connectivity diagrams, and the creation of a Bill of Materials (BoM).

It is necessary to choose a visual aid that is appropriate for the topic and audience.

Steel detailers now use these 3-D Modelling applications because they are specifically designed for steel detailing. The detailer can create the project in 3D before producing detailed shop drawings from the model. Sometimes, the software makes connections and details automatically without redrawing from scratch.

Steel detailers might work as an employee or subcontractors for steel fabricators. Their primary mission is to provide shop drawings illustrating how to make each steel part required for a construction project. However, generating shop drawings is not their only responsibility.

For instance, detailers ensure that all steel components work together with the components of other building trades and meet the architectural and structural requirements in the construction design drawings. Beyond shop drawings, the detailer supplies the fabricator with an advanced material list to order raw materials, electronic files for programming CNC machinery, material files for production tracking software, and separate sub-assembly details for making standard parts, bolt ordering lists, and bolt placement lists.

The steel detailer often manages the RFI (Request for Information) process with the general contractor to resolve disputes, get information, and coordinate with other subcontractors. The detailer also collaborates with the contractor and design team during the approval process, during which the architect and engineer review and approve the completed shop drawings.

The detailer also coordinates with the fabricator’s personnel, engineers, material suppliers, joist and deck manufacturers, and erectors to ensure everything comes together smoothly.

Book a 60-minute demo to see

how eziil mrp solution works for you

What is the Relationship Between the

Steel Detailer and the Fabricator?

A simplified explanation of the relationship between the detailer and the fabricator would look like this: The architect designs the structure’s look, while the engineer estimates the required sizes and locations of the steel to ensure the structure’s strength and safety.

Finally, the steel detailer uses both sets of plans to provide detailed drawings with dimensions for each part the welder and installer will use.

What Does a Steel Detailer Job

Description Look Like?

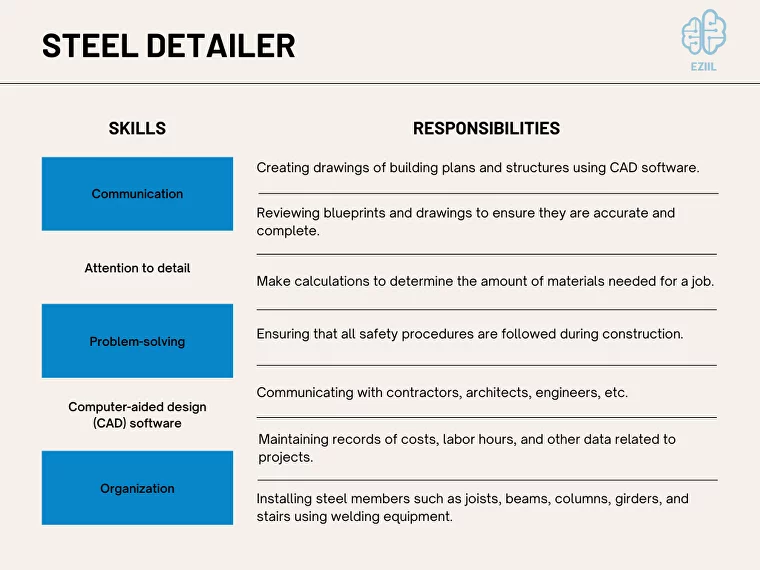

Using detailing software and computer-assisted design (CAD) programs, structural steel detailers create drawings and plans for steel buildings, bridges, and other fabrications.

They first gather information on the area’s community and environmental aspects, discuss the project’s specifications and expectations with their clients, review 3D models, manage the project’s preparation, and ensure the structure meets building standards.

Planning, collaborating, and cooperating with fabricators, architects, and other engineers are some of the soft skills required throughout a project to certify that it will be completed by the deadline and within budget.

How does one become a structural steel detailer?

To become a steel detailer, it is essential to be well-informed on drafting and proficient in industrial software, such as AutoCAD, Autodesk Advance Steel, Tekla 3D Modeling, or Revit. Candidates should be familiar with the shop and erection process for steel, having completed a structural detailing certificate program from a vocational school or community college.

Some employers consider candidates with expertise in drafting and construction experience, even without formal training.

In addition to drafting skills, a structural steel detailer needs an understanding of the materials used in steel erection and knows industry regulations. Other qualifications include excellent math skills, multitasking ability, attention to detail, and strong communication skills.

What is the steel detailer salary?

The salaries of structural steel detailers in the US range from $77,126 to $79,248, with a median salary of $79,248. The middle 50% of Structural Steel Detailers make $77,126, with the top 75% earning $95,098.

Conclusion

Structural steel detailing is essential in steel construction projects to transform comprehensive documentation into detailed drawings and explanations. Many engineering companies and contractors use subcontracted steel detailing services. However, hiring outsourced companies that provide detailing services for the construction industry is also a trend that ensures every project is executed by experienced professionals who will deliver on time, finish within a budget, and comply with the highest industry standards.