Welders are one of the essential tools in the manufacturing industry for joining metals and other materials. So many welding processes could be needed, and no single welding machine fits them all. As a result, at least ten different welder types are available to handle most welding projects.

Each machine type has its unique features and capabilities with variations in price and characteristics. Here is a look at the most popular welding machine types and some you might not be as familiar with, along with their uses:

1. Shielded Metal Arc Welding Machine (Stick)

Stick welding uses an electric current between the base metal and the stick (filler rod) to generate heat for welding. The filler rod is covered with a flux that prevents oxidation and contamination by producing carbon dioxide gas during welding. SMAW machines are operated by both AC and DC currents.

SMAW welders are among the most economical welders recommended for steel, inox steel

, and cast iron. Stick welding is ideal for open spaces and outdoor use, such as pipeline welding, construction, farm equipment repairs, steel erection, and maintenance.

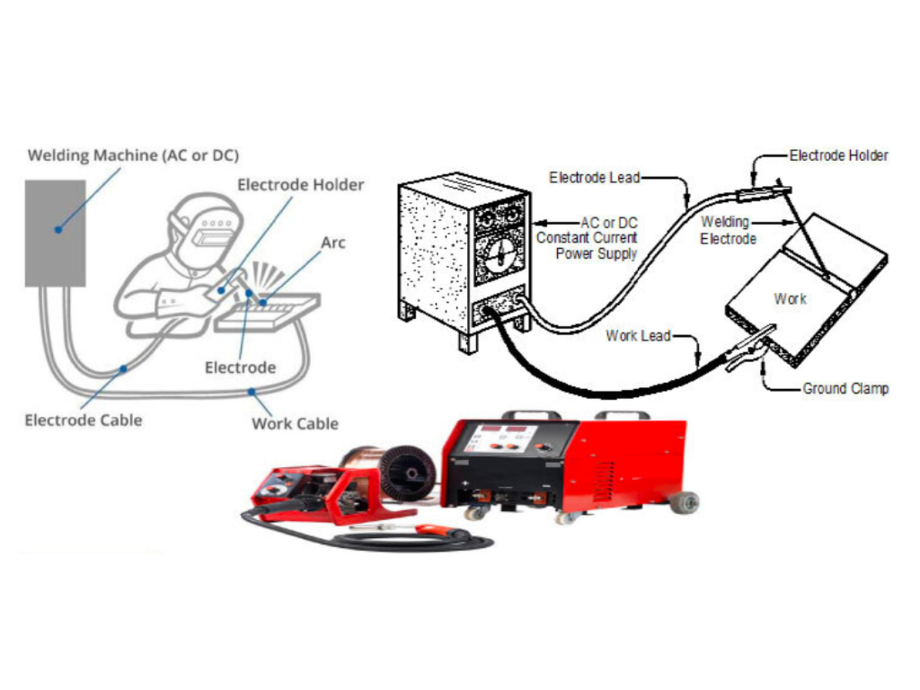

2. MIG Welding Machine

Image credit: https://www.weldman.net

MIG welding is one of the more accessible types of welding to learn. Metal inert gas welding, as it’s officially called, is typically used for large and thick materials. MIG machines use a consumable wire as an electrode and a filler material, resulting in a faster process and lower production costs.

The machines are usually accompanied by an external gas tank containing a shielding gas, typically Argon. A MIG welders works well with stainless steel, aluminum, magnesium, carbon steel, copper, and other metals. You’ll find these machines in the automotive, construction, shipyards, robotics, farms, and home workshops.

MIG Welders:

MIG (Metal Inert Gas) welding machines are one of the most commonly used welders in the industry. They use a consumable wire electrode that is fed through the machine, and a shielding gas, typically a mixture of argon and carbon dioxide, to protect the weld pool from contamination. MIG welders are versatile and can be used to weld a variety of materials, including carbon steel, stainless steel, and aluminum.

MIG Welder Types:

There are various types of MIG welders, including basic MIG welders, multi-process welders, and pulse MIG welders. Basic MIG welders are ideal for light-duty welding projects, while multi-process welders can handle a range of welding techniques, including MIG, TIG, and stick welding. Pulse MIG welders are designed for high-quality, precision welding projects, and use advanced technology to regulate the welding current and voltage.

3. TIG Welding Machine

Image credit: https://ipotools.eu

Tungsten inert gas welding (TIG) machines are preferred for thin metals and smaller projects. They produce precise and clean welds but require more experience and some multitasking compared to other techniques. The machine operator must hold the welding torch in one hand while feeding the filler wire with the other. The process requires a non-consumable tungsten electrode to produce a weld.

Unlike stick welding, TIG machines need a clean, rust-free surface to create a quality weld. The machines are used to weld steel, inox steel

, Chromoly, aluminum, nickel alloys, magnesium, Titanium, copper, brass, and bronze.

TIG helps repair lawnmowers, bike frames, door handles, fenders, etc. TIG’s other applications include pipeline welding, aerospace, race car fabrication, artwork, and motorcycles.

4. Flux-Cored Arc Welding Machine

Picture credit: https://www.diytrade.com

Flux core welders are generally used for thick metals and out-of-position welding. FCAW machines work equally well indoors and outdoors, and because they use a continuously-fed flux-filled electrode, there is no need for external shielding gas or to stop and restart the weld.

These welders produce less electrode waste and fewer fumes than other methods while operating at extremely hot temperatures, approaching 1000 amps. Although similar to the MIG welding process, FCAW is considered more powerful and uses a different gas shield.

Flux-cored arc machines are recommended for carbon steels, cast iron, nickel-based alloys, and some inox steel. They are popular in construction and fabrication applications.

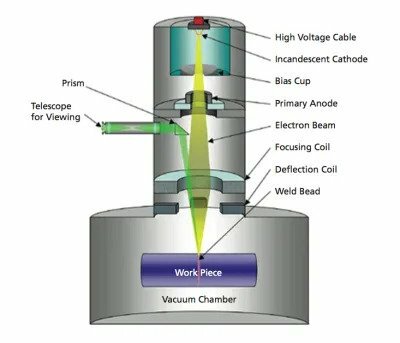

5. Energy Beam Welding Machine

Picture credit: https://www.techbriefs.com

The EWB machine employs a high-speed stream of tightly-focused electrons using magnetic fields and is applied to the base materials. The machine can join thick metals with thin metals or fuse different metals, and EWB can also weld specific points on the metals with little or no heat distortion in the welded areas.

Because the welder must perform this welding in a vacuum to prevent the electron beam from being absorbed by the air, the machine is not for home use. However, EWB is frequently used in power generation environments, plus the automotive, defense, medical, aerospace, and oil and gas industries.

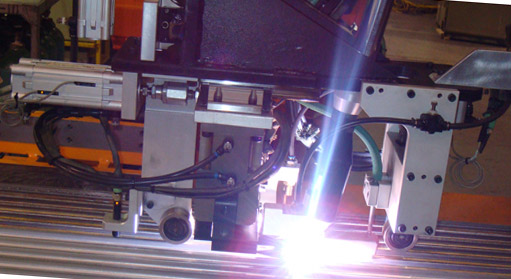

6. Plasma Arc Welding Machine

Picture credit: https://weldguru.com

Plasma-transferred stick welding machines (PTAW) are industrial-sized machines similar to TIG welders but with an anode surrounding the tungsten electrode. This anode constricts the arc to a laser-like precision and acts as a shield for the electrode, protecting it from the filler used in this process. Primarily used in the aircraft manufacturing industry, these welders are much more expensive than those we have discussed.

7. Submerged Arc Welding Machine

Image credit: https://www.cruxweld.com

Submerged arc welding machines involve creating an electric arc between a continuously fed electrode and the workpiece. A reusable powder flux replaces the gas shield, and the machines produce high-quality welds.

Because this is an automatic or semi-automatic system, the operator only needs a little experience with the machine. The primary downside to this machine is that it is not portable. These machines work well with steel, stainless steel, and steel and nickel alloys and are often found in plumbing, pipeline, and pressure vessel applications.

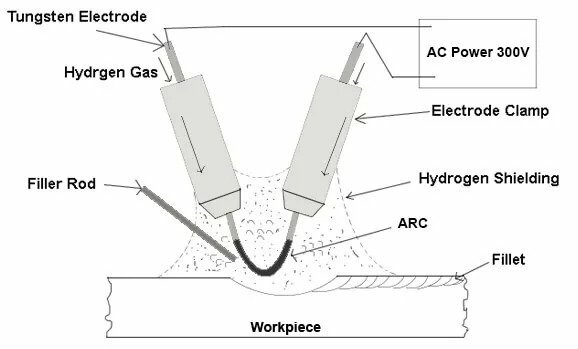

8. Atomic Hydrogen Welding Machine

Image credit: https://www.weldinginfo.org

Atomic hydrogen welding (AHW) machines use an arc generated between two tungsten electrodes and hydrogen shielding gas from an external cylinder. It’s called atomic hydrogen welding because the arc separates the hydrogen into atomic form.

These welding machines require an experienced operator, and they are being replaced by the more popular MIG welders, partly because AHW is more costly. AHW machines are suitable for thin and thick materials and rapid welding situations.

Stainless steel, ferrous metals, non-ferrous metals, and some alloys are compatible with AHW.

9. Oxyacetylene Gas Welding Machine

Picture credit: https://extrudesign.com

The oxyacetylene welder uses a fuel gas (usually acetylene) and oxygen as the heating medium. The flame is the main component produced at the end of the torch since it melts the base metal and possible filler to form the weld.

Gas welding works better for thin materials and not as well for thick ones. Operators can control the temperature and weld beads by adjusting the oxygen-to-fuel gas ratio on the machine. These welders are still used worldwide because of their relatively low cost and portability.

The recommended metals to use with this machine are restricted to iron-based and ferrous. You can still find oxyacetylene welding in fabrication projects, plumbing, automotive repair, and fieldwork.

10. Multipurpose Welding Machines

Picture credit: https://www.thomasnet.com

In addition to welder performing one type, multi-process welders can do two or three types on one machine. For example, 3-in-1 welders will perform TIG, MIG, and stick welding on the same machine, and others are capable of TIG and stick with a plasma cutter included.

You might need to purchase additional accessories to change the process, but you will not need to buy three separate machines!

A Few Lesser-Known Welding Machines

Although MIG, TIG, and stick welding dominate today’s welding, they do not perform all of it. Here are a few machines you may have heard of—or perhaps not:

- Spot welder Spot welding is a type of resistance welding that combines two or more metal sheets by applying heat and pressure to the weld area with an electric current.

- Thyristor MIG welder: These machines are ideal for steel and aluminum because of their high output and precise work. Thyristors are often used in automotive repair shops, construction sites, and manufacturing plants for joining sheet metal or repairing machinery.

- Transformer welder: Within the welding machine, the transformer converts the high-voltage input from the wall plug, usually from 208 to 600 volts, with a low alternating current (AC) from 15 to 55 amps.

- Rectifier welder: This machine is an electric device that joins two pieces of metal. It is composed of a power source that converts AC into DC and then sends it through electrodes attached to the joined metal pieces. The DC creates heat and melts the metal pieces together, forming a solid bond.

- Converter welder: A converter welding machine is an advanced technology using electrical current to create heat and melt metals. It is frequently used for stick welding since it makes higher-quality welds than most traditional methods.

Samples of lesser-known welding machines

Carbon Dioxide Welders

Carbon dioxide (CO2) welders are a type of welding machine that utilize CO2 gas to shield the welding arc and protect the weld pool from atmospheric contamination. These machines are often used for MIG welding, a popular welding process that uses a consumable wire electrode and a shielding gas to join two pieces of metal. CO2 welders are widely used in the automotive industry and are suitable for welding a variety of materials, including stainless steel and aluminum.

Welding Helmets

Welding helmets are essential pieces of protective equipment that shield the welder’s face and eyes from harmful radiation and debris. They come in a range of styles and designs, from basic models that cover the face to advanced auto-darkening helmets that adjust the shade of the lens based on the welding arc’s intensity.

Arc Length

Arc length is an important consideration when welding. It is the distance between the end of the welding wire and the workpiece. Keeping the correct arc length is crucial for producing a strong and consistent weld. A longer arc length can cause excessive spatter, while a shorter arc length can lead to a shallow weld.

Welding Table

A welding table is a specialized piece of equipment designed for holding the workpiece during welding. It provides a stable and secure surface for welding projects, allowing for precise and accurate welds. Welding tables are typically made of heat-resistant materials and can withstand the high temperatures generated during welding.

Welding Wire

Welding wire is the consumable material used in welding machines to join two pieces of metal. The type of welding wire used depends on the welding project’s requirements and the welding machine being used. For example, MIG welding wire is typically used in MIG welding machines and requires a shielding gas, such as CO2 or a mixture of argon and CO2.

Welding Project

A welding project refers to any welding work that needs to be completed, whether it is a small DIY project or a large-scale industrial project. The type of welding machine and welding equipment used will depend on the requirements of the project and the materials being welded.

MIG Welding Gas

MIG welding gas is a shielding gas used in MIG welding machines. It helps to protect the weld pool from atmospheric contamination and ensure a clean and strong weld. The type of MIG welding gas used will depend on the welding project’s requirements and the materials being welded.

Welding Torch

A welding torch is a handheld tool used in various welding machines, such as MIG welding machines and TIG welding machines. It is used to direct the heat and flame to the workpiece and welding wire, creating the weld. The type of welding torch used will depend on the welding machine being used and the welding project’s requirements.

Welding Equipment

Welding equipment refers to the various tools and machines used in welding, such as welding machines, welding torches, welding tables, and welding helmets. Choosing the right welding equipment is crucial for achieving optimal results and ensuring the safety of the welder.

Filler Metal

Filler metal is a type of welding wire used to fill gaps in the weld joint or add additional material to the weld. It is typically used in MIG welding and TIG welding machines and is available in various types and sizes, depending on the welding project’s requirements.

Weld Metal

Weld metal is the metal that is fused together during the welding process. It is created by melting the welding wire and the workpiece, allowing them to combine and solidify.

Flux Core Wire

Flux core wire is a type of welding wire that contains a flux compound, eliminating the need for a separate shielding gas in the welding process. It is commonly used in MIG welding machines for welding projects in outdoor or windy conditions.

Weld Bead

A weld bead is the visible seam created by the welding process. It is formed by the molten metal that has cooled and solidified, creating a strong and durable weld.

Welding Gun

A welding gun is a handheld tool used in MIG welding machines. It is attached to the welding wire and directs the heat and shielding gas to the workpiece

Conclusion

There are too many welding processes and machines to cover in one article, just as there are endless areas using welding in their manufacturing projects.

Suffice it to say that for every welding task in construction, aerospace, pipelines, rail lines, tubes, steel, automobile, shipbuilding, electronics, solar, and storage tanks, a welding machine will be available to handle it.

In addition, we recommend checking out a very popular YouTube channel with extensive welding content by Jody Collier. His channel offers: “Clear arc shots and plain talk to help you pass a test”, “fix stuff”, “build stuff”, “get a raise”.

Watch this informative video about various welding machine types and techniques on Jody Collier’s YouTube channel.